Method and device for recycling printed circuit board waste copper liquid

A technology of printed circuit boards and electrolysis devices, applied in chemical instruments and methods, electrolysis processes, electrolysis components, etc., can solve problems such as the reduction of electrolysis reaction rate, the precipitation of chlorine gas at the anode of the electrolysis cell, and the harm to the health of workshop workers, so as to increase the purity , Improve environmental friendliness, and promote the effect of copper ion precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

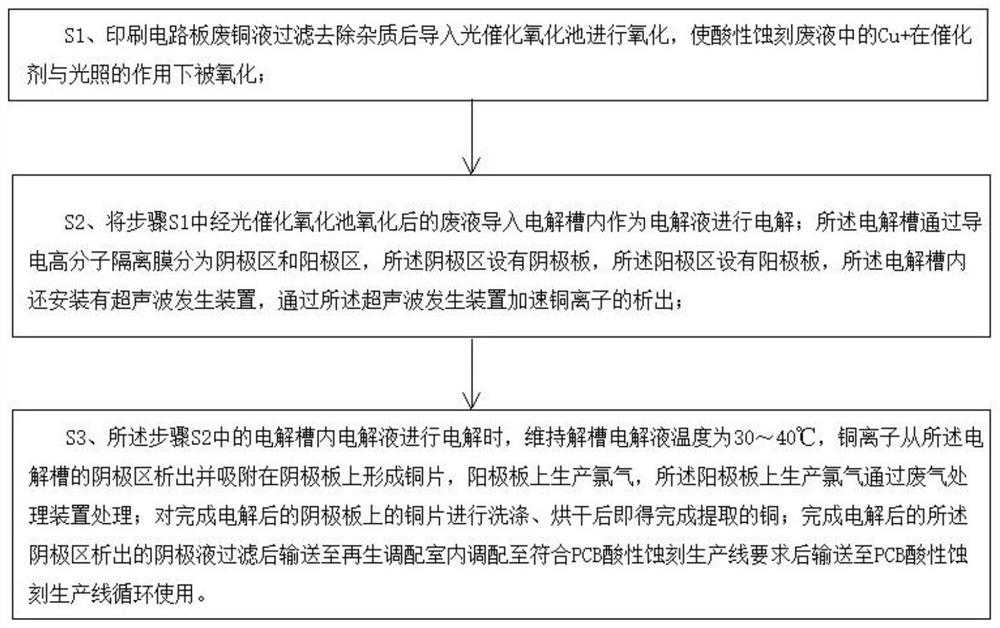

[0036] refer to figure 1 Shown, a kind of printed circuit board waste copper solution recycling method comprises the following steps:

[0037] S1. After the printed circuit board waste copper liquid is filtered to remove impurities, it is introduced into the photocatalytic oxidation tank 2 for oxidation, so that Cu+ in the acidic etching waste liquid is oxidized under the action of catalyst and light;

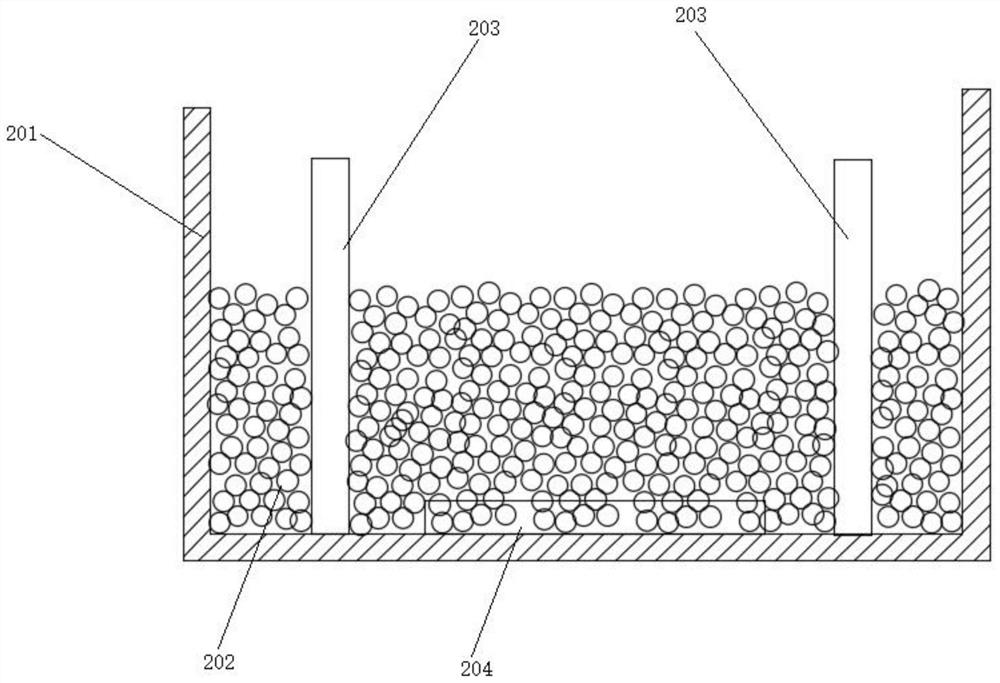

[0038] S2. In step S1, the waste liquid oxidized by the photocatalytic oxidation cell 2 is introduced into the electrolytic cell 301 for electrolysis as the electrolyte; the electrolytic cell 301 is divided into a cathode area and an anode area through a conductive polymer isolation film 302, and the cathode area is provided with The cathode plate and the anode area are provided with an anode plate, and an ultrasonic generator 327 is also installed in the electrolytic cell 301, through which the ultrasonic generator 327 accelerates the precipitation of copper ions;

[0039] S3...

Embodiment 2

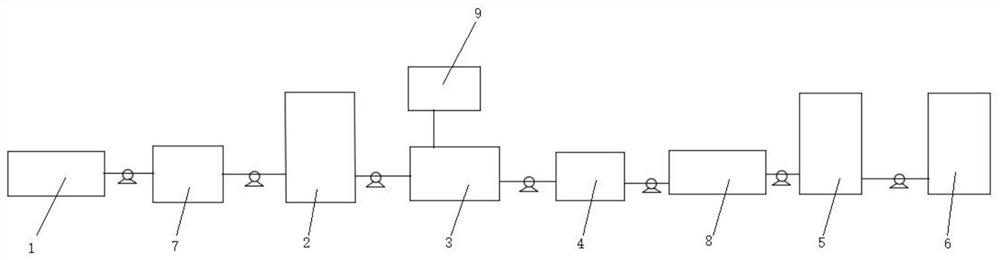

[0041] Such as figure 2 As shown, a printed circuit board waste copper liquid recycling device includes a waste liquid tank 1, a photocatalytic oxidation tank 2, an electrolysis device 3, a first regeneration liquid storage tank 4, a regeneration preparation chamber 5, and a second regeneration liquid storage tank. Tank 6, first filter 7, second filter 8 and waste gas treatment device 9; electrolysis device 3 includes water inlet, water outlet and gas outlet, and the acidic etching wastewater produced on the PCB acidic etching production line is stored in the waste liquid tank 1, The waste liquid tank 1 is sequentially connected with the first filter 7, the photocatalytic oxidation cell 2, and the water inlet of the electrolysis device 3 through a pipeline with a pump. The pump pipeline is connected with the first regeneration liquid storage tank 4 , the second filter 8 , the regeneration preparation chamber 5 and the second regeneration liquid storage tank 6 .

[0042] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com