Quasi-solid-state battery positive electrode slurry as well as preparation method and application thereof

A battery cathode, quasi-solid-state technology, applied in electrode manufacturing, battery electrodes, batteries, etc., can solve the problems affecting the cycle stability and safety of the battery cell, reducing the peel strength of the pole piece, and reducing the stability of the slurry, etc. Cycling stability and rate capability, inhibiting lithium dendrite growth, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

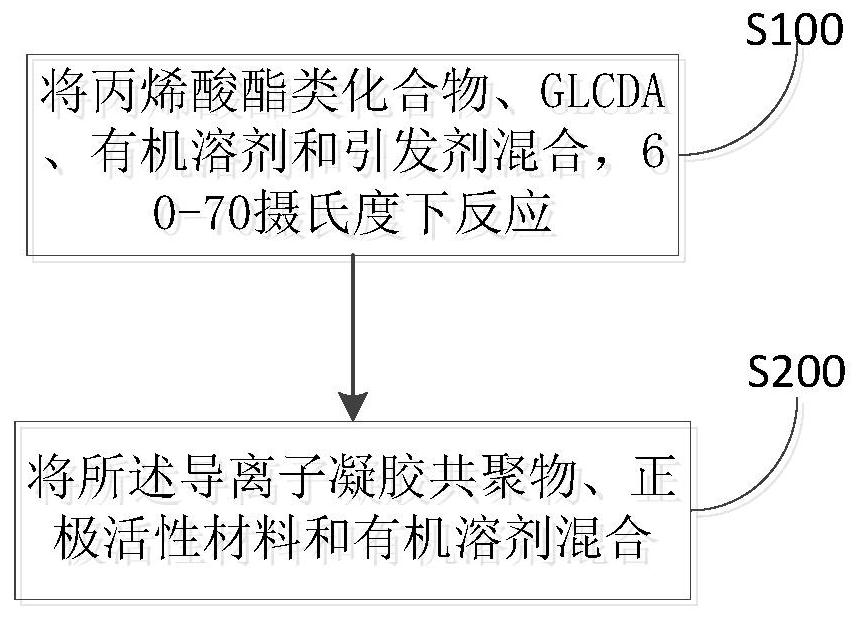

Method used

Image

Examples

preparation example Construction

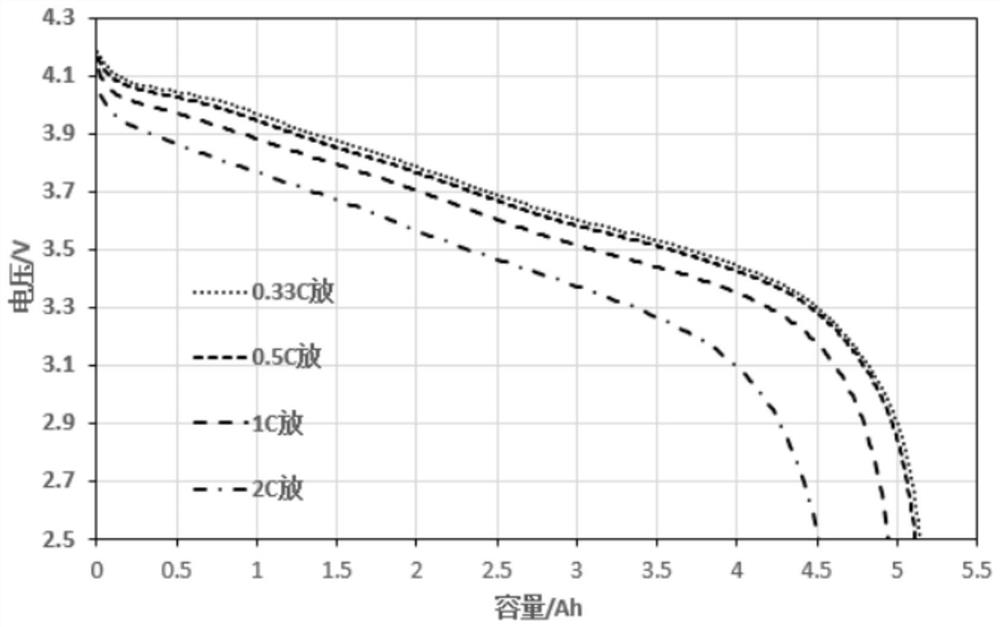

[0073] According to the method for preparing the above-mentioned quasi-solid-state battery positive electrode slurry according to the embodiment of the present invention, the method significantly increases the stability of the homogenate coating process by introducing an ion-conducting gel copolymer, and improves the rate performance and cycle performance of the battery. The use of electrolyte is reduced to improve the safety performance of the battery. Specifically, the ion-conducting gel copolymer can be used as Li + Transport carrier, undertake the role of the solvent in the electrolyte to synergistically promote Li + Transmission in the pole piece; in addition, the mechanical properties of the pole piece are improved by introducing ion-conducting gel copolymer, which endows the pole piece with flexibility, which can effectively relieve the volume expansion of the pole piece during charge and discharge, and improve the electrode material The stability of the Li + The tran...

Embodiment 1

[0079] 1) Preparation of ion-conducting copolymer:

[0080] Stir 0.1kg triethylene glycol dimethacrylate, 3.5kgNMP, 0.01kgEC and 0.002kgGLCDA with a homogenizer to obtain a clear solution, then add 0.12kgLiTFSI and 0.07kgSP to make a clear glue solution, and then add 0.07kg Azepanitril, 18h at 70°C, prepared a brown glue solution, that is, an ion-conducting gel copolymer.

[0081] 2) Preparation of ternary cathode slurry:

[0082] Add 10 kg of ternary material (NCM) to the glue solution prepared in step 1), and mix evenly to prepare ternary positive electrode slurry.

[0083] 3) Preparation of ternary positive pole piece:

[0084] Apply the ternary positive electrode slurry prepared in step 2) with a laboratory automatic coater, and apply the gap between the coating blades (adjust the target surface density: 15mg / cm 2 ), apply the slurry on the aluminum foil, and bake the coated electrode sheet at 120°C for 10 minutes to obtain the ternary positive electrode sheet.

Embodiment 2

[0086] 1) Preparation of ion-conducting copolymer:

[0087] Stir 0.08kg ethylene glycol dimethacrylate, 3kgNMP, 0.012kgPC and 0.0024kgGLCDA with a homogenizer to obtain a clear solution, then add 0.07kgLiPF 6 Stir with 0.12kg of VGCF to prepare a clear glue solution, then add 0.12kg of azobiheptanonitrile for 12 hours at 70°C to prepare a brown glue solution, that is, an ion-conducting gel copolymer.

[0088] 2) Preparation of ternary cathode slurry:

[0089] Add 10 kg of ternary material (NCM) to the glue solution prepared in step 1), and mix evenly to prepare ternary positive electrode slurry.

[0090] 3) Preparation of ternary positive pole piece:

[0091] Apply the ternary positive electrode slurry prepared in step 2) with a laboratory automatic coater, and apply the gap between the coating blades (adjust the target surface density: 15mg / cm 2 ), apply the slurry on the aluminum foil, and bake the coated electrode sheet at 120°C for 10 minutes to obtain the ternary posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com