Marinated meat sauce and marinated meat making method and equipment

A production method and technology for braised meat, which are applied in the functions of food ingredients, food ingredients as taste improvers, and food ingredients as anti-microbial preservation, etc., can solve the problem of loss of chewiness and smoothness of muscle fibers, and difficulty in marinating muscle fibers in place. and other problems to achieve the effect of avoiding uneven cutting, avoiding drying, and meeting edible needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

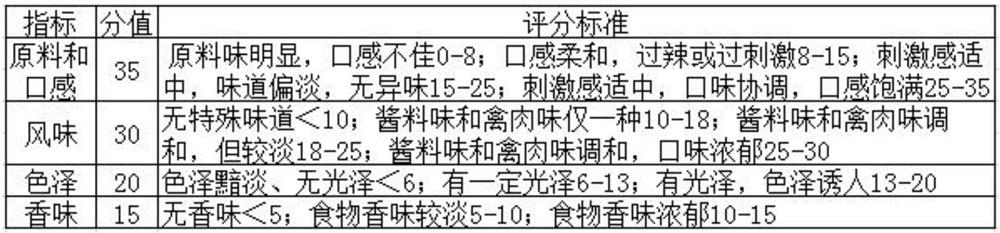

[0045] Preparation of marinated meat:

[0046] A. Stewing of brine: After weighing and mixing dried chili, Chinese prickly ash, table salt, cooking wine, star anise, tangerine peel, cinnamon bark and licorice according to a certain mass ratio, add boiling water and boil for 2-6 hours;

[0047] B. Prepare poultry meat: After the poultry meat is cleaned, shaped, trimmed, pickled and air-dried, the thickness of the poultry meat is controlled to 2-12cm, and it is refrigerated for later use;

[0048] C. Cooking: boil the poultry in step B for 20-40 minutes at a temperature of 90-100°C in brine, then lower the temperature and continue to keep warm for 1-3 hours, take out the meat and drain the brine to obtain brine meat;

[0049] Making the sauce:

[0050] D. Seasoning pretreatment: chop the washed and dried seasoning and mix evenly, weigh 1 / 3-1 / 2 of the quality of cooking oil, heat the cooking oil until the oil temperature is 60-80°C , add seasoning and stop heating cooking oil; ...

Embodiment 1

[0067] Take duck meat as an example:

[0068] A braised meat sauce, comprising the following raw materials by mass: 20 parts of edible oil, 4 parts of table salt, 1 part of edible gum, 1.5 parts of starch, 2 parts of seasoning, 2 parts of fermented soybean juice, 1 part of honey and food additives 0.1 part.

[0069] The soybean juice fermented product is fermented after soybeans are pulverized and squeezed for juice. The solid active ingredient concentration of the soybean juice fermented product is 18%. The fermentation includes anaerobic fermentation and aerobic fermentation performed by lactic acid bacteria and yeast. The condiments include ginger juice, dried chili, spice powder, soy sauce and oyster sauce. The food additives include compound seasonings and compound phosphates, and the compound phosphates include sodium tripolyphosphate and sodium hexametaphosphate.

[0070] A method for making stewed meat, comprising preparation of stewed meat, preparation of sauce and ...

Embodiment 2

[0082] Take duck meat as an example:

[0083] A braised meat sauce, comprising the following raw materials by mass: 10 parts of edible oil, 3 parts of table salt, 0.05 part of edible gum, 1-2 parts of starch, 1 part of condiment, 0.5 part of fermented soybean juice, 0.5 part of honey and Food additive 0.05 parts. The soybean juice fermented product is fermented after soybeans are pulverized and squeezed for juice. The solid active ingredient concentration of the soybean juice fermented product is 2%. The fermentation includes anaerobic fermentation and aerobic fermentation performed by lactic acid bacteria and yeast. The condiments include ginger juice, dried chili, spice powder, soy sauce and oyster sauce. The food additives include compound seasonings and compound phosphates, and the compound phosphates include sodium tripolyphosphate, sodium hexametaphosphate, sodium pyrophosphate and trisodium phosphate.

[0084] A method for making stewed meat, comprising preparation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com