Material pretreatment method for preparing tea theanine

A technology of tea theanine and pretreatment, which is applied in the field of separation and purification of theanine in tea leaves, can solve the problems of increasing the pressure of sewage treatment, increasing the production process steps, and taking a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

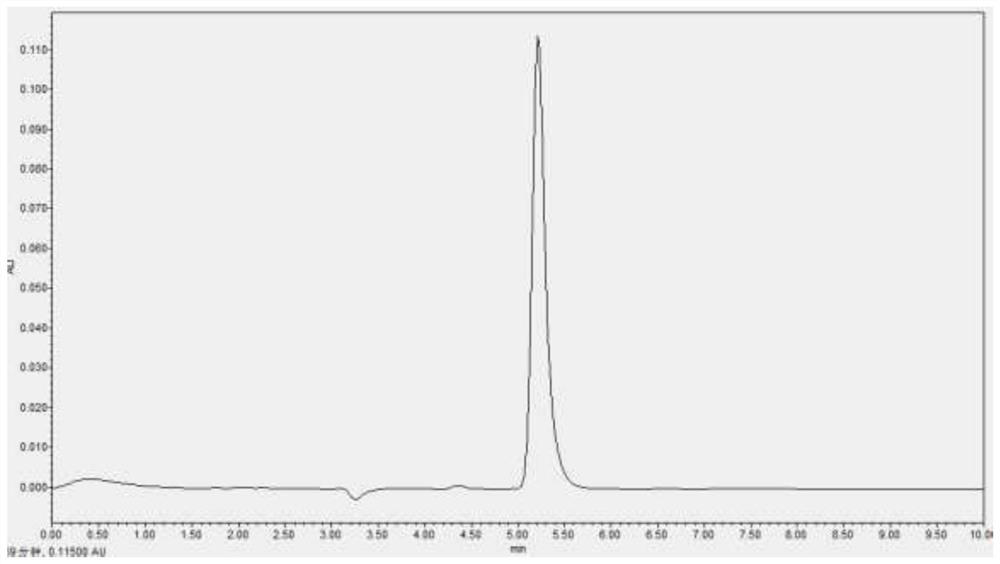

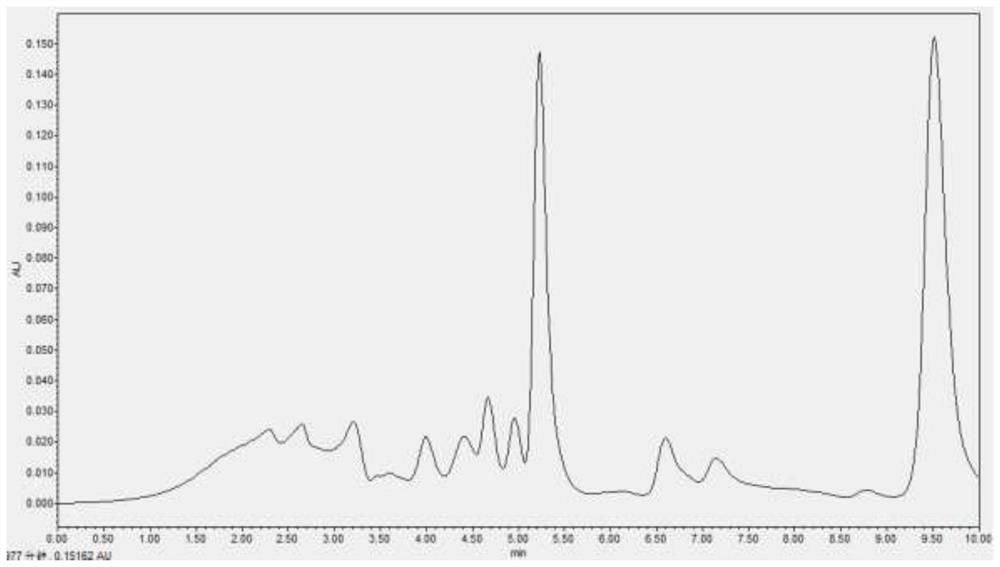

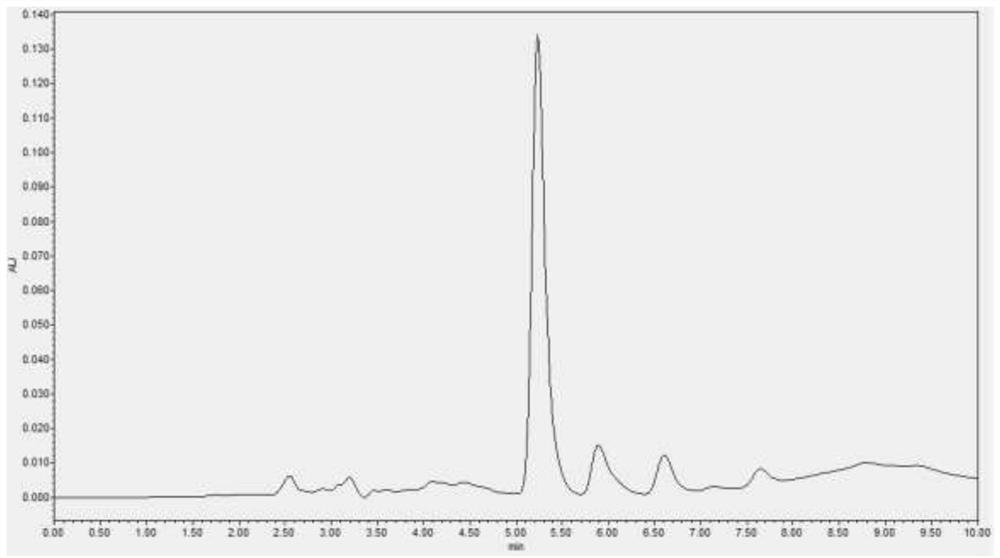

Image

Examples

Embodiment 1

[0034] (1) Collect the waste liquid produced by the production of tea polyphenols in the workshop;

[0035] (2) Dilute the waste liquid with purified water to a concentration of 7.6Brix (use ATAGO PAL-1 portable sugar meter to detect the concentration of the diluted waste liquid, the same below);

[0036] (3) Then use the prepared NaOH solution (mass fraction 50%) to adjust the pH of the waste liquid (monitor the pH value of the waste liquid with a pH meter, the same below): add NaOH solution while stirring until the pH value reaches 10.0, and the alkali-adjusting material is obtained ;

[0037] (4) Take 500mL 001×7 resin and put it on the chromatography column. After cleaning, put the base adjustment material directly on the column; control the flow rate of the column at 450mL / h, and load a total of 2503g on the column. After the column is finished, use the same Washing at a flow rate of 750mL, the washing liquid is incorporated into the effluent of the upper column; the eff...

Embodiment 2

[0040] (1) Collect the waste liquid produced by the production of tea polyphenols in the workshop;

[0041] (2) Dilute the waste liquid to a concentration of 8.0 Brix with purified water;

[0042] (3) Then use the prepared KOH solution (mass fraction 45%) to adjust the pH: add KOH solution while stirring until the pH value reaches 9.7, and the alkali adjustment material is obtained;

[0043] (4) Take 500mL 001×7 resin and put it on the chromatography column. After cleaning, put the base adjustment material directly on the column; control the flow rate of the column at 400mL / h, and load a total of 2507mL on the column. After the column is finished, use the same Washing at a flow rate of 750mL, the washing liquid is incorporated into the effluent of the upper column; the effluent of the upper column and the washing liquid are mixed evenly, which is the material for the preparation of theanine.

Embodiment 3

[0045] (1) Collect the waste liquid produced by the production of tea polyphenols in the workshop;

[0046] (2) Dilute the waste liquid to a concentration of 7.8Brix with purified water;

[0047] (3) Then use the prepared NaOH solution (50% mass fraction) to adjust the pH of the solution: add NaOH solution while stirring until the pH value reaches 9.5, and the alkali adjustment material is obtained;

[0048] (4) Take 700mL of 001×7 resin and put it on the chromatography column. After cleaning, put the base adjustment material directly on the column; control the flow rate of the column at 680mL / h, a total of 3502mL is loaded on the column, and wash with water at the same flow rate after the column is loaded , the amount of water washing is 1050mL, and the water washing liquid is merged into the effluent of the upper column. The effluent from the upper column and the washing liquid are evenly mixed, which is the material for preparing theanine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com