Homogeneous dispersion liquid of cross-linkable hydrocarbon resin composition, prepreg prepared from homogeneous dispersion liquid, and high-thermal-conductivity thermosetting copper-clad plate

A hydrocarbon resin, uniformly dispersed technology, applied in the field of communication materials, can solve the problems of limited thermal conductivity improvement of copper clad laminates, influence on the dielectric constant of copper clad laminates, limited addition of thermal conductive fillers, etc., to achieve uniform toughness and viscosity, good industrialization Proper base, toughness and stickiness are produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

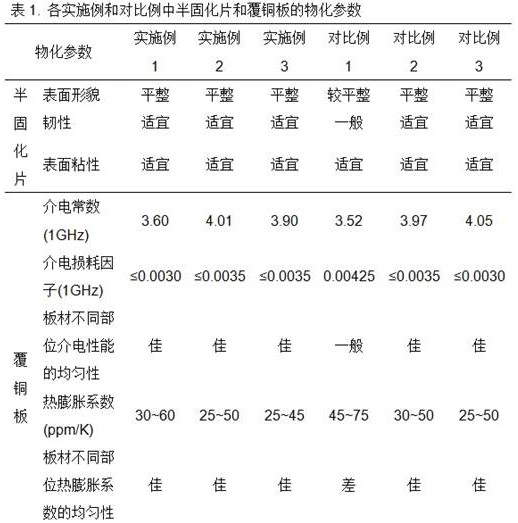

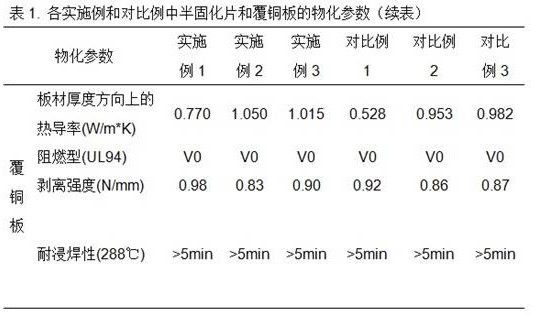

Examples

Embodiment 1

[0028] Take 18 parts of hexagonal AlN (D50=20um) and 60 parts of vinyl-terminated polyphenylene ether (Sabic SA9000) and disperse them in 600 parts of THF, take them out after ball milling for 12 hours, add excess deionized water to the system and The system was precipitated, and THF was fully removed by washing and filtering several times, and then the system was redispersed in water, and the water was removed by lyophilization to obtain a complex; then the complex was added to toluene, and 4 parts of hexagonal crystals were added at the same time Type BN (D50=1um), 3 parts of BN fiber (2~10um in diameter, 10~100um in length), 8 parts of alumina, 380 parts of silicon oxide, 60 parts of polybutadiene (Kray Willy Ricon130), 30 parts of polybutadiene (Craigville Ricon154), 15 parts of polydiene-styrene-divinylbenzene terpolymer (Craigville Ricon257), 5 parts of polybutadiene-maleic anhydride copolymer (Kray Willy Ricon130MA8), 5 parts of polystyrene-maleic anhydride copolymer (K...

Embodiment 2

[0030] Take 20 parts of hexagonal BN (D50=20um) and 25 parts of vinyl-terminated polyphenylene ether (Sabic SA9000) and disperse them in 800 parts of THF, take them out after ball milling for 12 hours, add excess deionized water to the system and The system was precipitated, and THF was fully removed by washing and filtering several times, and then the system was redispersed in water, and the water was removed by lyophilization to obtain a complex; then the complex was added to toluene, and 5 parts of hexagonal crystals were added at the same time Type BN (D50=1um), 7 parts of BN fiber (diameter 2~10um, length 10~100um), 12 parts of alumina, 120 parts of magnesium hydroxide, 35 parts of polybutadiene (Craig Willy Ricon130) , 10 parts polybutadiene (Crayville Ricon154), 6 parts polydiene-styrene-divinylbenzene terpolymer (Crayville Ricon257) and 5 parts polybutadiene-maleic anhydride Copolymer (Craig Willy Ricon130MA8), stirred at 50°C for 24 hours to fully dissolve and evenly ...

Embodiment 3

[0032] Take 10 parts of hexagonal BN (D50=30um), 5 parts of hexagonal BN (D50=10um), 5 parts of hexagonal AlN (D50=20um) and 25 parts of vinyl-terminated polyphenylene ether (Sabic SA9000) was dispersed in 600 parts of THF, taken out after ball milling for 12 hours, and excessive deionized water was added to the system to precipitate the system, and then THF was fully removed by repeated washing and filtration, and then the system was redispersed in water , the complex was obtained by lyophilization to remove water; then the complex was added to toluene, and at the same time, 3 parts of hexagonal BN (D50=1um), 5 parts of BN fiber (diameter 2~10um, length 10~100um ), 4 parts of AlN fiber (diameter 1~5um, length 10~50um), 12 parts of alumina, 100 parts of magnesium hydroxide, 15 parts of silicon oxide, 30 parts of polybutadiene (Kray Willy Ricon130), 15 parts Parts polybutadiene (Cray Willy Ricon 154), 6 parts polydiene-styrene-divinylbenzene terpolymer (Cray Willy Ricon 257), a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com