A kind of anti-marine biofouling coating and preparation method thereof

A marine biofouling and coating technology, applied in anti-fouling/underwater coatings, anti-corrosion coatings, alkali metal silicate coatings, etc. Long sterilization life, improve impermeability, and prevent substrate corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

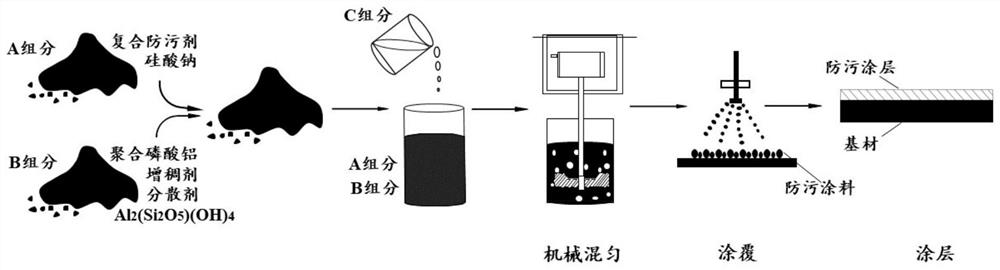

Method used

Image

Examples

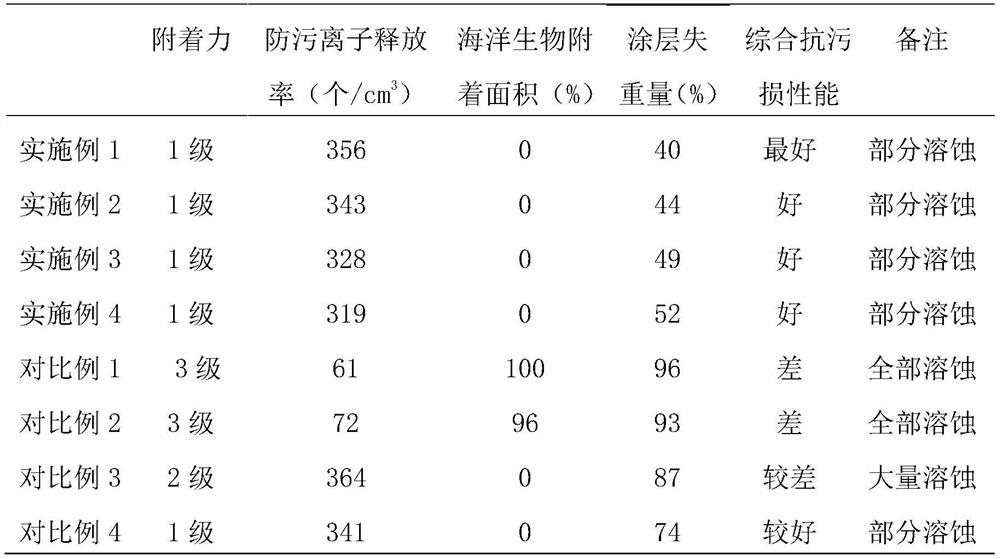

Embodiment 1

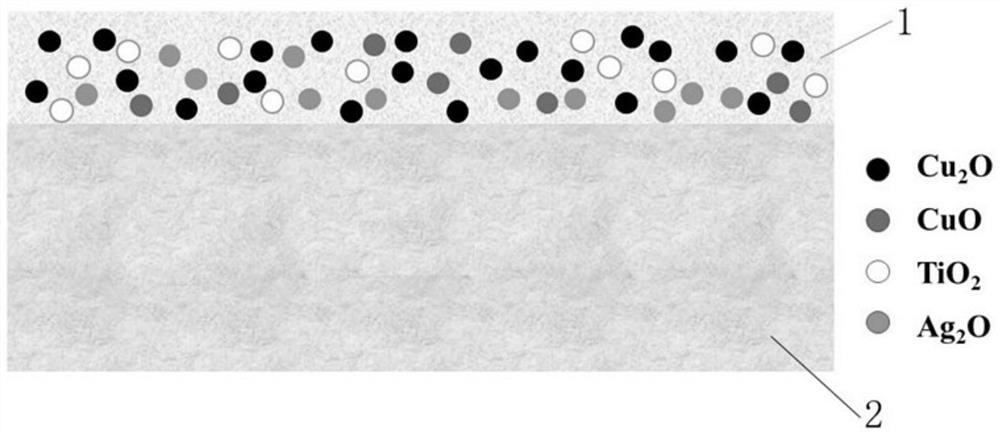

[0026] Weigh 15g of sodium silicate and 25g of composite antifouling agent with a median particle size of 80nm in proportion to mix and stir evenly. The composite antifouling agent includes Cu 2 O 10g, CuO 5g, TiO 2 5g, Ag 2 0 5g, obtain A component; Weigh in proportion to polyaluminum phosphate 10g, thickener sodium alginate 1g, hydroxyethyl cellulose 1g, Al 2 (Si 2 O 5 )(OH) 4 20g, dispersant calcium lignosulfonate 3g, mix and stir evenly to obtain B component; mechanically stir and mix A and B components, add 25g of C component water in proportion, and mechanically stir and mix to obtain anti-marine Biofouling paint.

[0027] The obtained anti-marine biofouling coating is evenly painted on the surface of the ceramic substrate, and after it is naturally cured and formed, a uniform and dense coating is formed on the surface of the ceramic substrate, which can effectively resist marine biofouling and protect the surface of the seawater immersion structure. Free from ma...

Embodiment 2

[0029] Weigh 17g of sodium silicate and 22g of composite antifouling agent with a median particle size of 120nm and mix them evenly. The composite antifouling agent includes Cu 2 O 10g, TiO 2 6g, Ag 2 0 6g, obtain A component; Weigh in proportion 11g of polyaluminum phosphate, thickener sodium alginate 1g, hydroxyethyl cellulose 0.6g, Al 2 (Si 2 O 5 )(OH) 4 18g, dispersant calcium lignosulfonate 2.4g, mix and stir evenly to obtain B component; mechanically stir and mix A and B components, add 28g of C component water in proportion, and mechanically stir and mix to obtain anti-oxidant. Marine biofouling paint.

[0030]The obtained anti-marine biofouling coating is evenly painted on the surface of the ceramic substrate, and after it is naturally cured and formed, a uniform and dense coating is formed on the surface of the ceramic substrate, which can effectively resist marine biofouling and protect the surface of the seawater immersion structure. Free from marine life. ...

Embodiment 3

[0032] Weigh 20g of sodium silicate and 18g of composite antifouling agent with a median particle size of 120nm and mix them evenly. The composite antifouling agent includes Cu 2 O 9g, Ag 2 0 9g, obtain A component; Weigh polyaluminum phosphate 13g, thickener sodium alginate 1.4g, Al 2 (Si 2 O 5 )(OH) 4 16g, dispersant calcium lignosulfonate 1.6g, mix and stir evenly to obtain B component; mechanically stir and mix A and B components, add 30g of C component water in proportion, and mechanically stir and mix; Marine biofouling paint.

[0033] The obtained anti-marine biofouling coating is sprayed on the surface of the concrete substrate, and after it is naturally cured and formed, a uniform and dense coating is formed on the surface of the concrete substrate, which can effectively resist marine biofouling and protect the surface of the seawater immersed structure from being damaged. Invasion of marine life. The resulting anti-marine biofouling coating eroded away in abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com