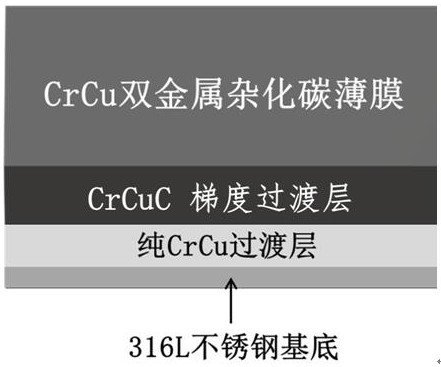

Preparation method of CrCuC gradient gradually-changed CrCu compound carbon thin film bipolar plate

A composite carbon and bipolar plate technology, which is applied to fuel cell components, ion implantation plating, fuel cells, etc., can solve the problem of PEMFC metal bipolar plates being easily corroded and passivated, and achieve improved hydrophobicity and high The effect of corrosion resistance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Polish the stainless steel (316L stainless steel) substrate, and ultrasonically clean it with acetone cleaning solution and ethanol cleaning solution for 15 minutes respectively to remove surface impurities and organic pollutants such as oil stains and rust spots, then dry it with nitrogen, and put it into a coating vacuum chamber Prepare for coating;

[0021] (2) Pump the vacuum system to 1.0×10 -3 Pa and below, pass in argon gas; turn on the high bias voltage, control the argon gas pressure 2.0Pa, bias voltage 800 V, etch and clean the target surface and stainless steel sample surface; the time is 15 min;

[0022] (3) The bias voltage was adjusted to 100 V, the argon gas pressure was 1.4-1.5 Pa, the pure CrCu metal transition layer was deposited by magnetron sputtering, the average current was 6.5 A, the voltage was 700 V, the duty cycle was 20%, and the pulse length was 3000 ms; The deposition time is 25 min, and the thickness of the CrCu metal transition layer ...

Embodiment 2

[0027] (1) Polish the stainless steel (316L stainless steel) substrate, and ultrasonically clean it with acetone cleaning solution and ethanol cleaning solution for 15 minutes respectively to remove surface impurities and organic pollutants such as oil stains and rust spots, then dry it with nitrogen, and put it into a coating vacuum chamber Prepare for coating;

[0028] (2) Pump the vacuum system to 1.0×10 -3 Pa and below, pass in argon gas; turn on the high bias voltage, control the argon gas pressure 1.5Pa, bias voltage 900 V, etch and clean the target surface and stainless steel sample surface; the time is 20min;

[0029] (3) The bias voltage was adjusted to 100 V, the argon gas pressure was 1.4-1.5 Pa, the pure CrCu metal transition layer was deposited by magnetron sputtering, the average current was 6.5 A, the voltage was 700 V, the duty cycle was 20%, and the pulse length was 3000 ms; The deposition time is 25 min, and the thickness of the CrCu metal transition layer i...

Embodiment 3

[0034] (1) Polish the stainless steel (316L stainless steel) substrate, and ultrasonically clean it with acetone cleaning solution and ethanol cleaning solution for 20 minutes respectively to remove surface impurities and organic pollutants such as oil stains and rust spots, then dry it with nitrogen, and put it into the coating vacuum Chamber preparation for coating;

[0035] (2) Pump the vacuum system to 1.0×10 -3 Pa and below, pass in argon gas; turn on the high bias voltage, control the argon gas pressure to 2.0Pa, and the bias voltage to 900 V, etch and clean the target surface and stainless steel sample surface; the time is 15 min;

[0036] (3) The bias voltage was adjusted to 130 V, the argon gas pressure was 1.4-1.5 Pa, the pure CrCu metal transition layer was deposited by magnetron sputtering, the average current was 6.5 A, the voltage was 700 V, the duty cycle was 20%, and the pulse length was 3000 ms; The deposition time is 25 min, and the thickness of the CrCu met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com