Cover plate type packaging structure and method for perovskite solar cell

A technology of solar cells and packaging structures, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of complicated packaging methods and high costs, achieve excellent mechanical properties and weather resistance, fully respond, and improve the effect of system strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

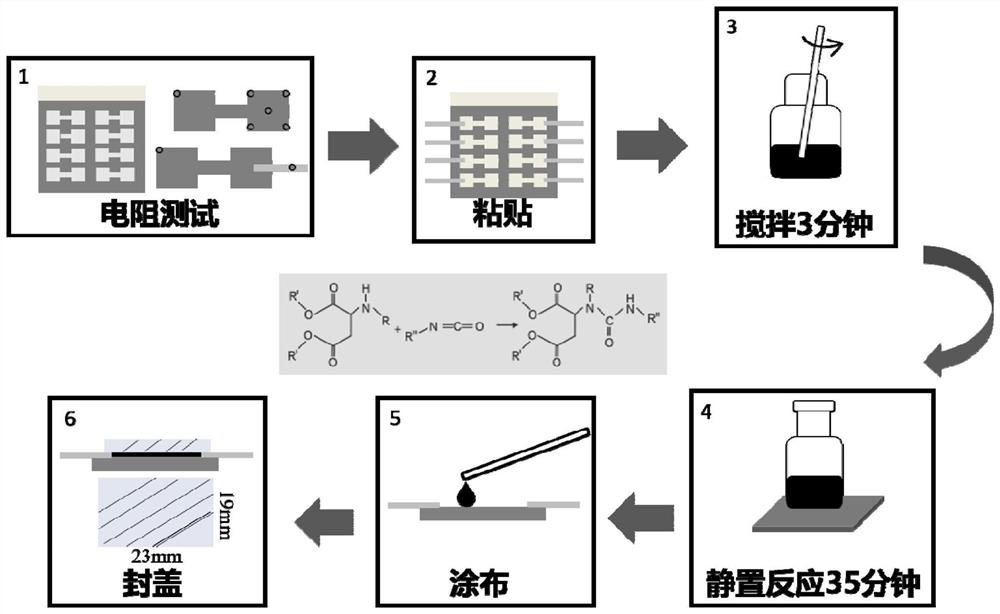

[0066]Step 1, the determination of the equivalent electrode resistance on the surface of the perovskite solar cell; use a compressed air spray gun with a working pressure of 0.4MPa to clean the surface of the prepared perovskite solar cell device, and use a multimeter to measure by the five-point sampling method The initial resistance R0 of each group of equivalent electrodes, after the measurement is completed, the surface is cleaned again.

[0067] Step 2, lead out the equivalent electrode; cut the copper tape with a resistivity of 0.03Ω / m into small pieces of 2mm*25mm, and paste each group of equivalent electrodes with a piece of folded copper tape, and measure again after the pasting is completed Lead-out resistance R1, when R1-R0≤±0.5Ω, it is regarded as effective lead-out, and the surface is cleaned with a compressed air spray gun after the lead-out treatment is completed.

[0068] Step 3, Stirring and mixing of the two-component sealant; Mix the A-component polyaspartat...

Embodiment 2

[0074] In this example, in step 3, the mixing ratio of component A polyaspartate and component B isocyanate is 2:1. After the mixing is completed, place it on a constant temperature magnetic stirrer and stir for 3 minutes. After stirring, the magnetic stirrer Recovery, the reagent bottle is removed from the mixer. The curing time in step 6 is 24h.

[0075] All the other unrelated parts are the same as in Example 1.

Embodiment 3

[0077] In this example, in step 3, the mixing ratio of component A polyaspartate and component B isocyanate is 2:1. After the mixing is completed, place it on a constant temperature magnetic stirrer and stir for 2 minutes. Recovery, the reagent bottle is taken off from the stirrer, and the curing time in step 6 is 30h.

[0078] All the other unrelated parts are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com