Technical wood material impregnation liquid, preparation method, treatment method and manufacturing process

A technology of manufacturing process and treatment method, applied in wood treatment, wood treatment details, manufacturing tools, etc., can solve the problems of yellowing, low peeling rate of impregnation, fading of technical wood, etc., and achieve the effect of high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

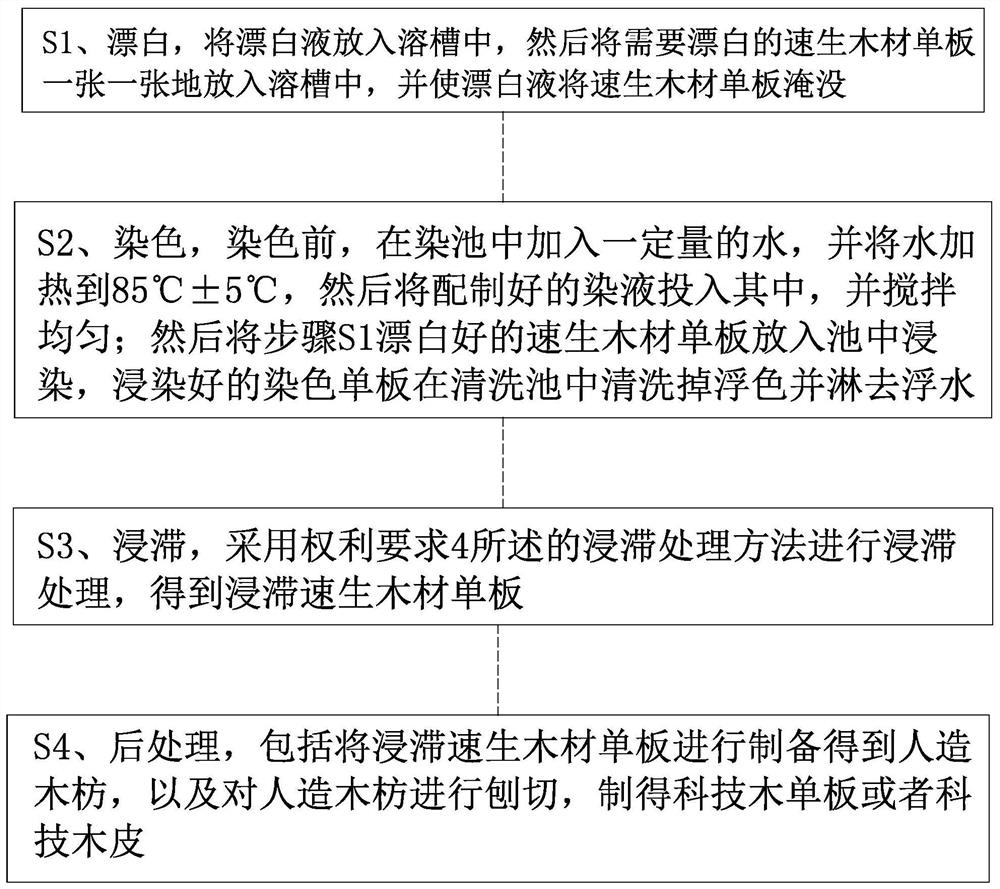

Method used

Image

Examples

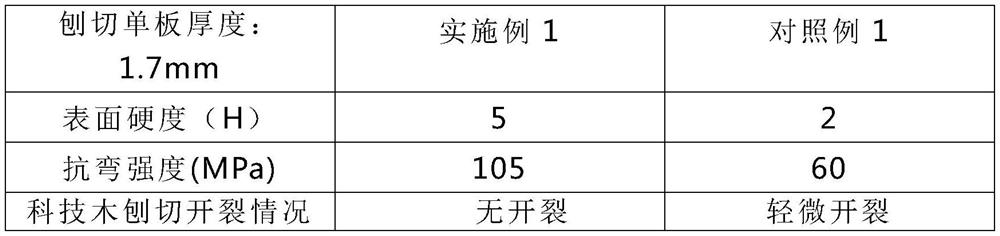

Embodiment 1

[0034] A technology wood material impregnation solution includes the following material components: water, silicone acrylic emulsion, light shielding agent, ultraviolet absorber, histamine free radical scavenger and emulsifier. Silicone acrylic emulsion itself has very good flexibility, adhesion and other advantages. Using the above-mentioned components to physically mix, the silicone acrylic emulsion at this time can fill the original gaps and wormholes of technical wood stained wood, etc. to fill the space, synergistically The characteristics of film formation at a lower temperature can make the technical wood stained wood have very good crack resistance and high density.

[0035] Secondly, the silicone acrylic emulsion cooperates with the histamine free radical scavenger, and the synergistic effect of the two can make the cured silicone acrylic emulsion have a long-term stable free radical or a substance that stabilizes molecules to ensure that the silicone acrylic emulsion ...

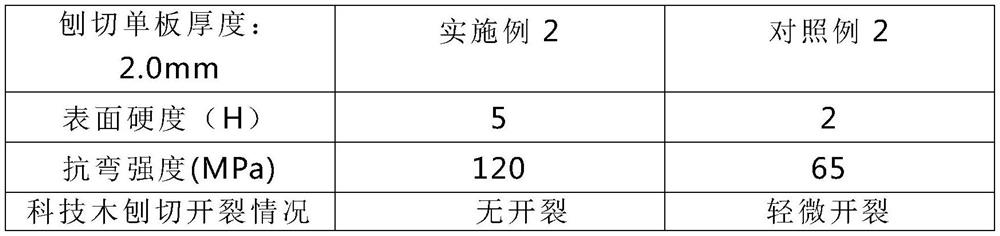

Embodiment 2

[0074] The working principle of the present embodiment is basically the same as that of Embodiment 1, the difference being that: according to the actual parts by weight: 100 parts of water, 15 parts of silicon-acrylic emulsion, 5 parts of light shielding agent, 2 parts of ultraviolet absorber, and 2 parts of histamine 1 part of free radical scavenger and 1 part of emulsifier.

[0075] Through the above dosage, it can achieve the following application test data:

[0076] The following is the veneer test data:

[0077]

[0078] The following is the veneer test data:

[0079] sliced veneer Example 2 Comparative example 2 Color fastness to light level 4 Level 1.5 Anti-yellowing E* 0.89 2.15 Slicing and cracking of technical wood no crack slightly cracked

Embodiment 3

[0081] The working principle of this embodiment is basically the same as that of Embodiment 1, the difference being: according to the actual weight parts as follows: 100 parts of water, 10 parts of silicon-acrylic emulsion, 1 part of light shielding agent, 5 parts of ultraviolet absorber, and 1 part of histamine 3 parts of free radical scavenger and 4 parts of emulsifier.

[0082] Through the above dosage, it can achieve the following application test data:

[0083] The following is the veneer test data:

[0084]

[0085] The following is the veneer test data:

[0086] sliced veneer Example 3 Comparative example 1 Color fastness to light Level 6 Level 1.5 Anti-yellowing E* 0.45 1.99 Slicing and cracking of technical wood no crack slightly cracked

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com