a g-c 3 n 4 Quantum dots and their preparation methods and applications

A technology of g-c3n4 and quantum dots, which is applied in the field of g-C3N4 quantum dots and its preparation, can solve the problems of cumbersome and difficult quantum dot methods and low yield, and achieve the effect of simple and fast method, stable performance and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

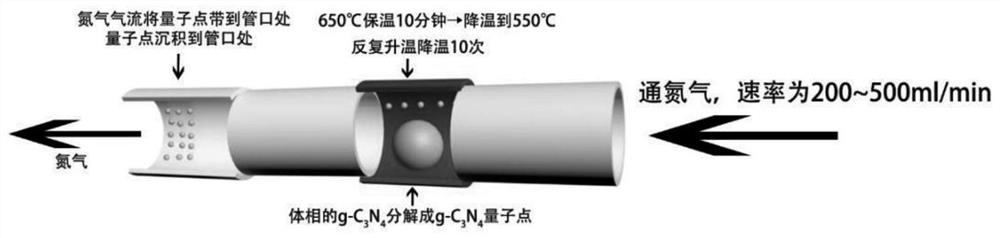

[0032] Embodiments of the present invention also provide the above-mentioned g-C 3 N 4 The preparation method of quantum dots, the principle is as follows figure 1 shown, including the following steps:

[0033] 1) The bulk phase g-C 3 N 4 Put it into the quartz crucible, and then put the quartz crucible into the middle of the tube furnace;

[0034] 2) Put the quartz glass beads into the second quartz crucible and place the second quartz crucible in the bulk phase g-C 3 N 4 downwind; alternatively, put the quartz glass beads into two second quartz crucibles and place the two quartz crucibles in the bulk phase g-C 3 N 4 After the upper tuyere and the lower tuyere are installed, the tube furnace is installed;

[0035] In the present invention, the quartz glass beads are placed in the bulk phase g-C 3 N 4 On both sides of the high-temperature calcination and decomposition, the small-sized g-C 3 N 4 Quantum dots are deposited on quartz glass beads for subsequent collec...

Embodiment 1

[0047] A high yield g-C 3 N 4 A rapid preparation method of quantum dots, the preparation method comprises the following steps:

[0048] 1 Preparation of bulk g-C 3 N 4 :

[0049] Weigh 20g of melamine, put it into a quartz crucible, heat it up to 550°C in a muffle furnace for 2h, keep it warm for 2h, take it out after cooling, it is the bulk phase g-C 3 N 4 .

[0050] 2. Preparation of g-C 3 N 4 Quantum dots:

[0051] 1) Weigh 15g bulk phase g-C 3 N 4 Put into the first quartz crucible, and then put the first quartz crucible into the middle of the tube furnace;

[0052] 2) Select spherical quartz glass beads with a diameter of 2-10 mm, put the quartz glass beads into two second quartz crucibles on average, and then place the two second quartz crucibles on both sides of the tube furnace respectively (that is, the body Phase g-C 3 N 4 On both sides of the tube furnace, corresponding to the upper tuyere and the lower tuyere of the tube furnace), install the tube fu...

Embodiment 2

[0056] A high yield g-C 3 N 4 A rapid preparation method of quantum dots, the preparation method comprises the following steps:

[0057] 1 Preparation of bulk g-C 3 N 4 :

[0058] Weigh 20g of melamine, put it into a quartz crucible, heat it up to 500°C within 2h in a muffle furnace, keep it warm for 4h, take it out after cooling, it is the bulk phase g-C 3 N 4 .

[0059] 2. Preparation of g-C 3 N 4 Quantum dots:

[0060] 1) Weigh 15g bulk phase g-C 3 N 4 Put into the first quartz crucible, and then put the first quartz crucible into the middle of the tube furnace;

[0061] 2) Select spherical quartz glass beads with a diameter of 2-10 mm, put the quartz glass beads into the second quartz crucible on average, and then place the two second quartz crucibles on both sides of the tube furnace respectively (i.e. the bulk phase g-C 3 N 4 On both sides of the tube furnace, corresponding to the upper and lower tuyere vents of the tube furnace), install the tube furnace; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com