Treatment method of circulating water sewage

A treatment method and sewage technology, which are applied in water/sewage treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of effectively removing the hardness of untreated sewage, and achieve easy operation and maintenance, and technical economy. Good, strong adaptability to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

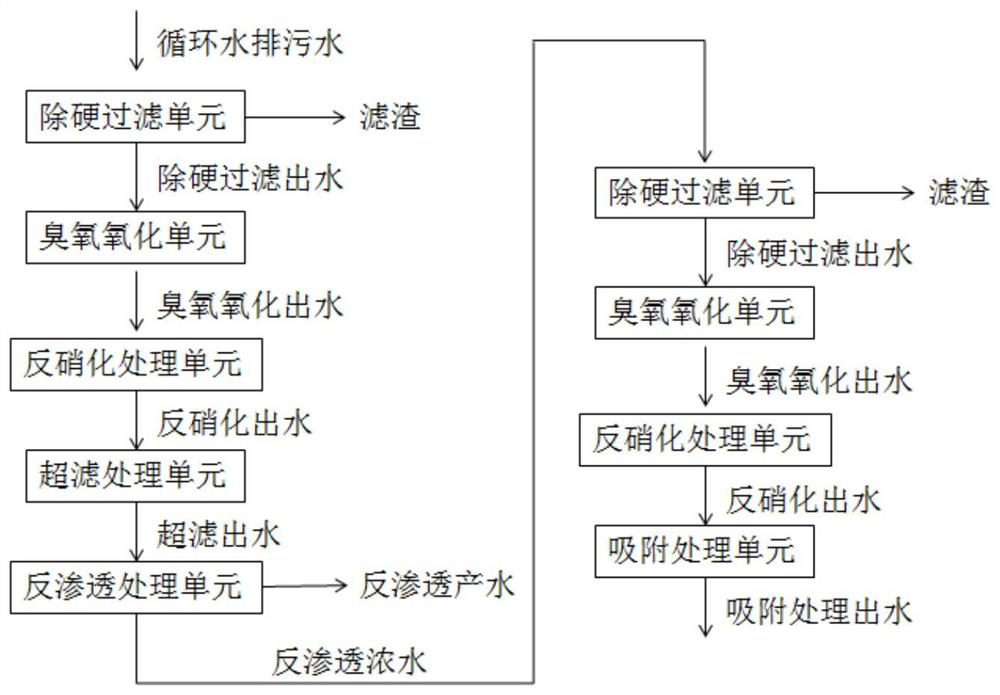

Image

Examples

Embodiment 1

[0052] The main water quality characteristics of circulating water sewage include: oil content 1.6mg / L, conductivity 2200μS / cm, suspended solids 95mg / L, COD 160mg / L, Cl - 470mg / L, SO 4 2- 620mg / L, dissolved silicon 45mg / L, pH 9, total nitrogen 40mg / L in terms of N element, total hardness 200.

[0053] The processing steps are as follows:

[0054] Step 1, the circulating water sewage enters into the high-efficiency hardening removal filter unit, and the hardening agent sodium hydroxide and sodium carbonate are added. After the circulating water sewage and the hardening agent are contacted and reacted, the pH of the water is controlled at 10.8, reacted for 20 minutes, and then the membrane Filtration to form high-efficiency hard-removal filtered water; the filtration pressure of the membrane filtration unit is 0.1MPa, the membrane material is polytetrafluoroethylene, and the membrane pore size is 0.2μm; the filter residues are solidified and then transported outside for treatm...

Embodiment 2

[0075] The main water quality characteristics of circulating water sewage include: oil content 1.4mg / L, electrical conductivity 3500μS / cm, suspended solids 110mg / L, COD 130mg / L, Cl - 500mg / L, SO 4 2- 660mg / L, dissolved silicon 70mg / L, pH 8, total nitrogen 25mg / L in terms of N element, total hardness 170.

[0076] The processing steps are as follows:

[0077] Step 1, the circulating water sewage enters into the high-efficiency hardness removal filter unit, and the hardening agents sodium hydroxide and sodium carbonate are added. After the circulating water sewage and the hardening agent are contacted and reacted, the pH of the water is controlled at 11.5, and the reaction is carried out for 25 minutes. After that, the membrane Filtration to form high-efficiency hard-removal filtered water; the filtration pressure of the membrane filtration unit is 0.1MPa, the membrane material is polytetrafluoroethylene, and the membrane pore size is 0.18μm; the filter residues are solidified...

Embodiment 3

[0098] The main water quality characteristics of circulating water sewage include: oil content 1.5mg / L, conductivity 4000μS / cm, suspended solids 100mg / L, COD 180mg / L, Cl - 550mg / L, SO 4 2- 700mg / L, dissolved silicon 55mg / L, pH 8.5, total nitrogen 35mg / L in terms of N element, total hardness 200.

[0099] The processing steps are as follows:

[0100] Step 1, the circulating water sewage enters into the high-efficiency dehardening filter unit, adding the hardening agents sodium hydroxide and sodium carbonate, the pH of the water after the contact reaction between the circulating water sewage and the hardening agent is controlled at 10.8, the circulating water sewage and the dehardening agent The hard agent is reacted for 25 minutes, and then membrane filtration is performed to form high-efficiency hard removal and filtered water; the filtration pressure of the membrane filtration unit is 0.1MPa, the membrane material is polytetrafluoroethylene, and the membrane pore size is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com