Preparation method and application of three-layer core-spun silicon carbide fiber wire

A core-spun silicon carbide and fiber technology, which is applied in fiber processing, braids, textiles and papermaking, etc., can solve the problems affecting the application range of two-dimensional SiC/SiC composite materials, the decrease of the interlayer bonding force of composite materials, and the impact on the mechanics of composite materials. Performance and other problems, to avoid poor high temperature oxidation resistance, reduce friction and extrusion stress, and broaden the effect of engineering application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

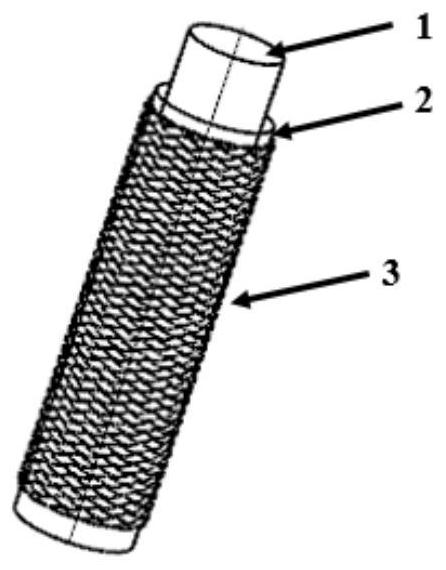

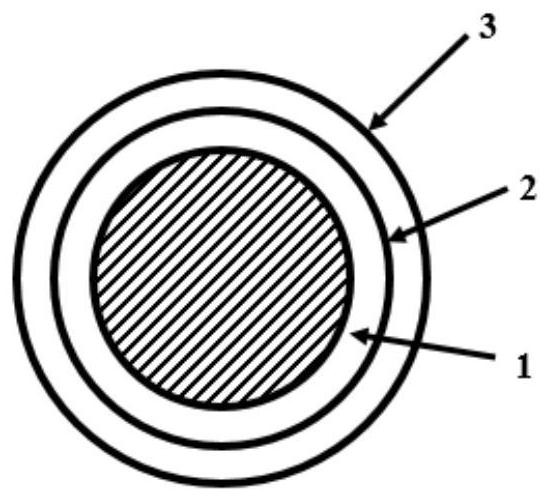

[0027] Such as figure 1 As shown, the three-layer core-spun silicon carbide fiber wire includes a SiC fiber core wire 1, the outer side of the SiC fiber core wire 1 is a polytetrafluoroethylene intermediate layer 2, and the outermost layer is an aramid outer wrapping layer 3, wherein the polytetrafluoroethylene intermediate layer The thickness of layer 2 is 0.01mm-0.15mm, and the thickness ratio of SiC fiber core wire, polytetrafluoroethylene intermediate layer and aramid outer wrapping layer is (60-75):(10-15):(10-30);

[0028] The three-layer core-spun silicon carbide fiber wire is made by the following method:

[0029] (1) Determine the SiC fiber core thread: According to the suture specification and strength requirements of the SiC fiber fabric, determine the number of single filaments in the SiC fiber core thread tow as 0.5k, and select the domestic second-generation SiC fiber;

[0030] (2) Preparation of the polytetrafluoroethylene intermediate layer: through the pultru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com