Preparation method of platinum/titanium carbide nanosheet/graphene three-dimensional composite electrode catalyst

An electrode catalyst, three-dimensional composite technology, applied in battery electrodes, nanotechnology, nanotechnology and other directions, can solve the problems of limiting the ion transmission speed of the electrolyte, reducing the electrochemical activity, reducing the catalytic efficiency, etc., and achieving a simple and controllable preparation method. Conducive to large-scale industrial production, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

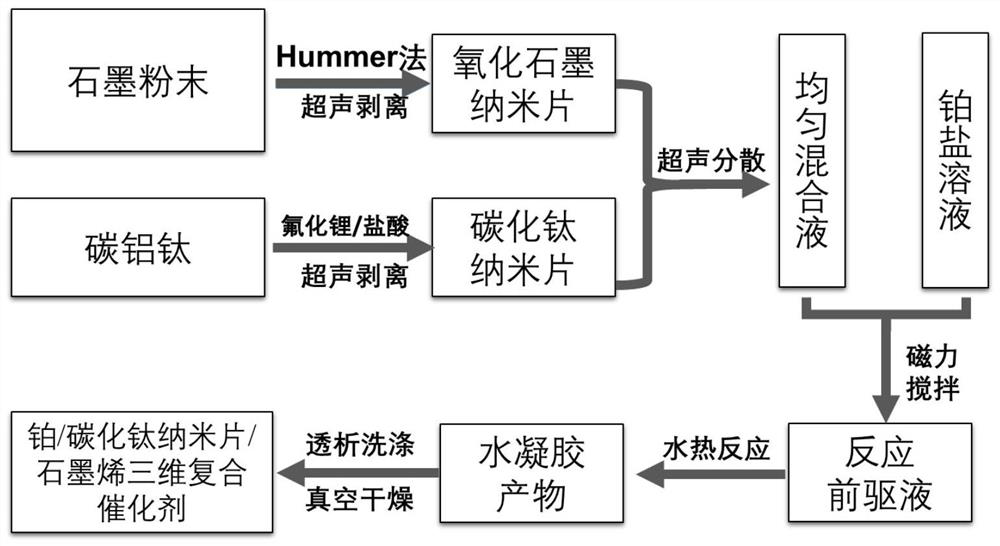

[0040] Such as figure 1 , a preparation method of platinum / titanium carbide nanosheet / graphene three-dimensional composite electrode catalyst, comprising the following steps:

[0041] S1, preparing a titanium carbide nanosheet dispersion;

[0042] S2. Add graphene oxide to the titanium carbide nanosheet dispersion in step S1, the amount of graphene oxide and titanium carbide added is 1 to 9:9 to 1 in mass ratio, and ultrasonic at a temperature of 0 to 50°C Disperse for 0.5-6 hours to obtain a titanium carbide nanosheet / graphene oxide binary composite solution;

[0043] S3, adding potassium chloroplatinite solution to the binary composite solution in step S4, the addition amount of platinum element and titanium carbide nanosheet / graphene oxide binary composite in the potassium chloroplatinite solution is by mass ratio Calculated as 1-20:1-20, stirred at 0-50°C for 0.2-5h to obtain potassium chloroplatinite / titanium carbide nanosheet / graphene oxide ternary composite solution; ...

Embodiment 1

[0050] A preparation method of platinum / titanium carbide nanosheet / graphene three-dimensional composite electrode catalyst, comprising the following steps:

[0051] S1, preparing a titanium carbide nanosheet dispersion;

[0052] S2. Add graphene oxide to the titanium carbide nanosheet dispersion in step S1, the amount of graphene oxide and titanium carbide added is 9:1 by mass ratio, and ultrasonically disperse at a temperature of 10°C for 1 hour to obtain titanium carbide Nanosheet / graphene oxide binary composite solution;

[0053] S3, adding potassium chloroplatinite solution to the binary composite solution in step S2, the addition amount of platinum element and titanium carbide nanosheet / graphene oxide binary composite in the potassium chloroplatinite solution is by mass ratio Calculated at a ratio of 1:9, stirred at 20°C for 40 minutes to obtain a ternary composite solution of potassium chloroplatinite / titanium carbide nanosheets / graphene oxide;

[0054] S4. Put the ter...

Embodiment 2

[0060] A preparation method of platinum / titanium carbide nanosheet / graphene three-dimensional composite electrode catalyst, comprising the following steps:

[0061] S1, preparing a titanium carbide nanosheet dispersion;

[0062] S2. Add graphene oxide to the titanium carbide nanosheet dispersion in step S1, the amount of graphene oxide and titanium carbide added is 4:5 by mass ratio; ultrasonically disperse for 3 hours at a temperature of 30° C. to obtain titanium carbide Nanosheet / graphene oxide binary composite solution;

[0063] S3, adding potassium chloroplatinite solution to the binary composite solution in step S2, the addition amount of platinum element and titanium carbide nanosheet / graphene oxide binary composite in the potassium chloroplatinite solution is by mass ratio Calculated at a ratio of 1:7, stirred at 10°C for 30 minutes to obtain a ternary composite solution of potassium chloroplatinite / titanium carbide nanosheets / graphene oxide;

[0064] S4. Put the tern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com