Method for in-situ additive preparation of intermetallic compound component based on additive manufacturing method

An intermetallic compound and additive manufacturing technology, which is applied in the field of intermetallic compound preparation, can solve the problems of high preparation cost, difficult processing of intermetallic compound components, and difficulty in small batch production, and achieve low processing cost, high density, The effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

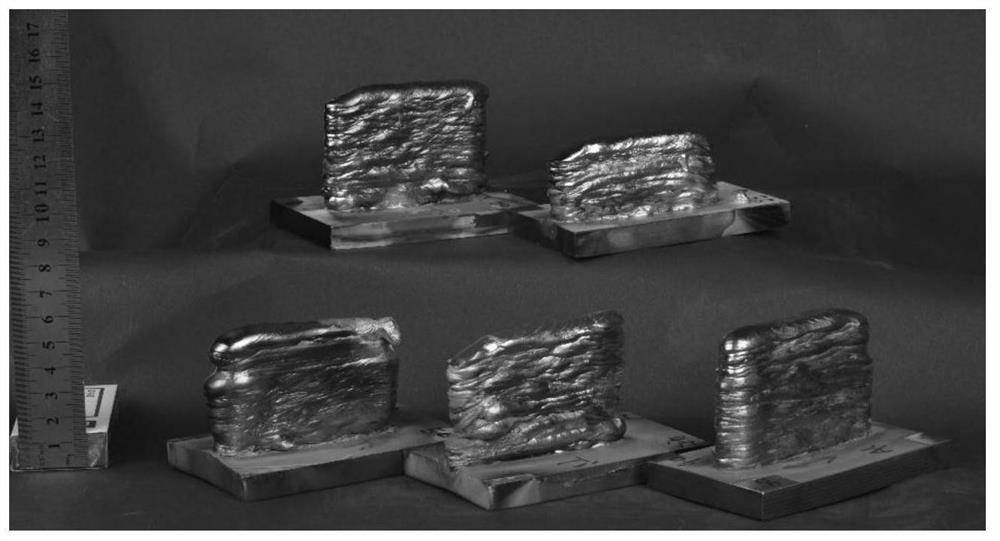

[0046] This embodiment is to use electron beam twin-filament fuse in-situ additive to prepare titanium-aluminum intermetallic compound, including the following steps:

[0047] (1) Preliminary preparation: place the aluminum wire and titanium wire on different wire feeders of the electron beam fused wire additive system, adjust the angle and height of the wire feed gun, and fix the titanium alloy substrate after sanding and ethanol cleaning on the electronic beam. Put the working platform on the working platform of the electron beam fused filament additive manufacturing system, and place the working platform in the vacuum chamber of the electron beam fused filament additive manufacturing system. When the vacuum degree reaches the working vacuum degree, use a small beam to preheat the substrate until the titanium alloy substrate appears red hot;

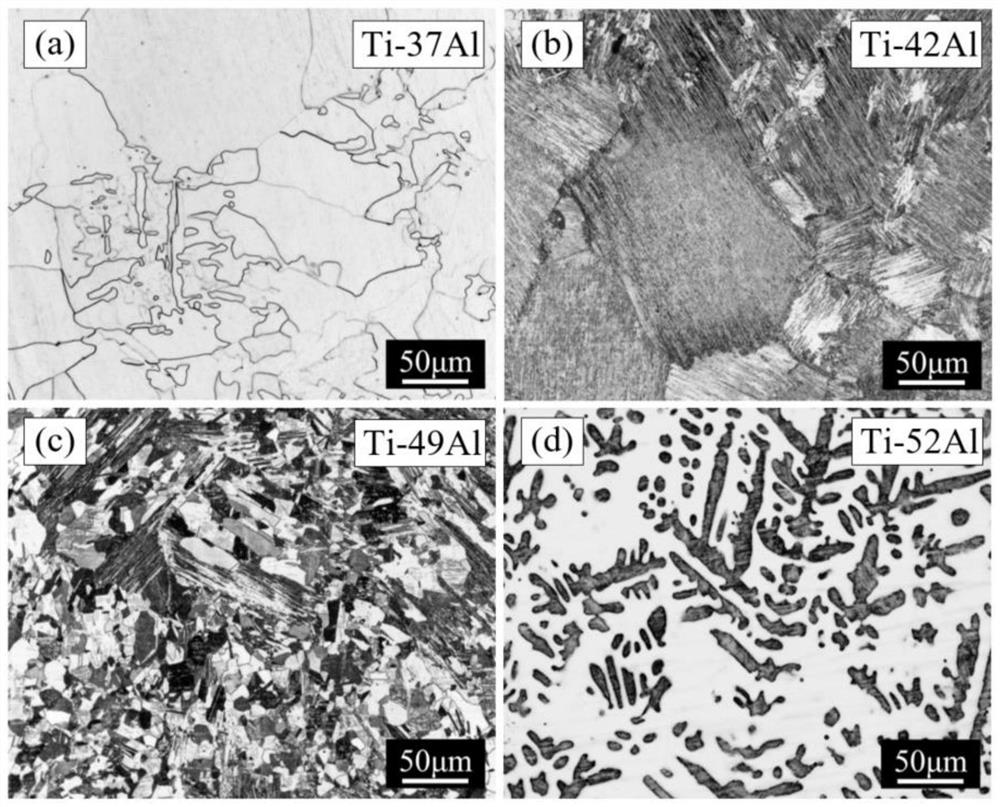

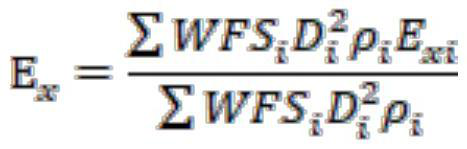

[0048] (2) In-situ material addition: After setting the wire feeding speed of aluminum wire and titanium wire, feed the wire at the s...

Embodiment 2

[0058] This embodiment is to prepare nickel-aluminum intermetallic compounds by in-situ addition of plasma arc fuses, including the following steps:

[0059] (1) Preliminary preparation: place the aluminum wire and nickel wire on different wire feeders of the plasma arc fuse additive system, adjust the angle and height of the wire feed gun, and fix the pure nickel substrate after sanding and ethanol cleaning on the melting wire feeder. On the working platform of the silk additive manufacturing system, and turn on the substrate preheating device to heat the substrate to 400 °C;

[0060] (2) In-situ material addition: After setting the wire feeding speed of aluminum wire and titanium wire, feed the wire at the same time, feed it into the same molten pool, and deposit it according to the set path, after depositing a single pass, cool to 400°C and continue carry out the deposition until the deposition is complete;

[0061] (3) Cooling of additive components: the nickel-aluminum i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com