Preparation method of low-cost low-temperature lithium iron phosphate

A lithium iron phosphate, low temperature technology, applied in chemical instruments and methods, phosphorus compounds, structural parts, etc., can solve the problems of high cost and poor low temperature performance, reduce environmental pressure, good performance, and broad market application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

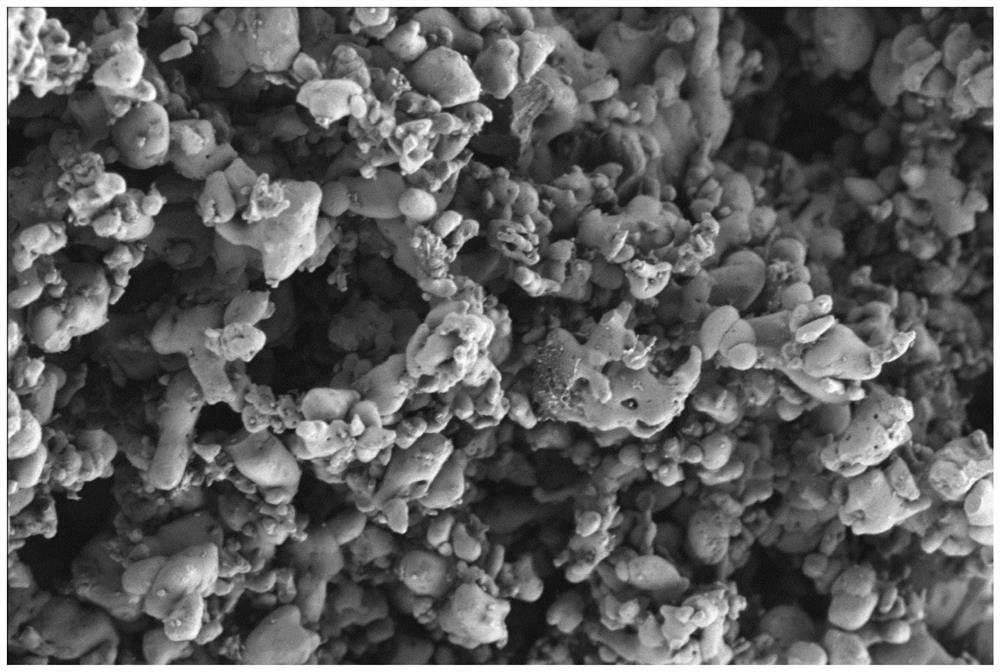

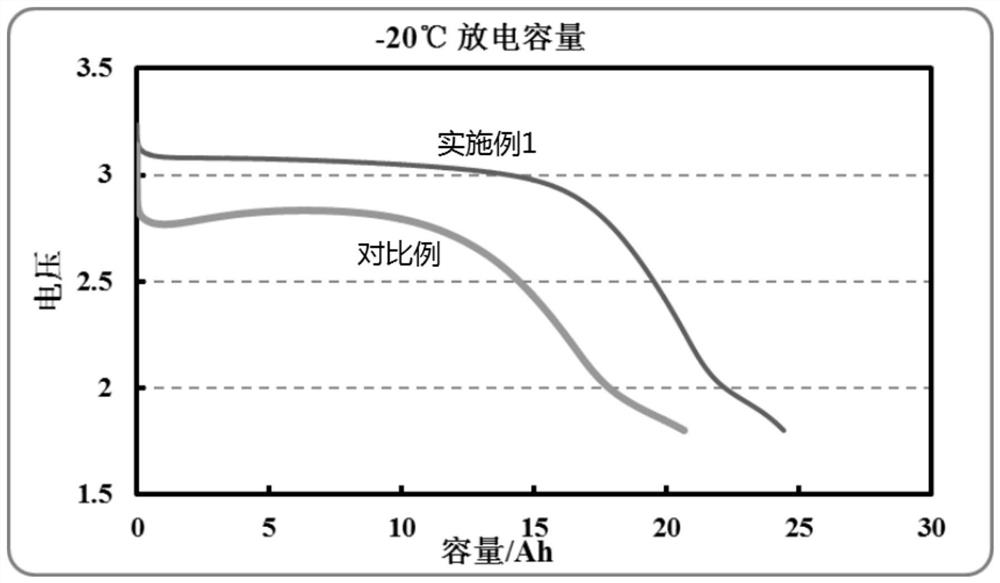

Image

Examples

Embodiment 1

[0029] A method for preparing low-cost low-temperature lithium iron phosphate, comprising the following steps:

[0030] S1, transfer the chemical chrome plating waste liquid into the filter tank with a mesh aperture of 50 orders (that is, the aperture is 150 μm) and filter to remove small particle impurities in the waste liquid;

[0031] S2, adding concentration is the photochemical oxidizing agent ozone (O of 3mg / L) in chemical plating waste liquid 3 ), the hypophosphite and phosphite ions in the electroless chrome plating waste liquid are oxidized into orthophosphate ions, and the reaction time is 1.5h;

[0032] S3, in the solution treated in step S2 according to phosphate ion and Fe 3+ Add ferric nitrate at a molar ratio of 1.10:1, after stirring and mixing for 3.5 hours, adjust the pH value to 2.0, and react at a temperature of 65°C;

[0033] S4, subjecting the reacted product to aging, press filtration, washing, and pulping to obtain iron phosphate slurry;

[0034] S5....

Embodiment 2

[0042] A method for preparing low-cost low-temperature lithium iron phosphate, comprising the following steps:

[0043] S1, transfer the chemical chrome plating waste liquid into the filter tank with a mesh aperture of 50 orders (that is, the aperture is 150 μm) and filter to remove small particle impurities in the waste liquid;

[0044] S2, adding concentration to the chemical chrome plating waste liquid is the photochemical oxidant ozone (O 3 ), the hypophosphite and phosphite ions in the electroless chrome plating waste liquid are oxidized into orthophosphate ions, and the reaction time is 1h;

[0045] S3, in the solution treated in step S2 according to phosphate ion and Fe 3+ The molar ratio is 1.15:1, adding ferric chloride, after stirring and mixing for 4 hours, adjust the pH value at 2.5, and react at a temperature of 70°C;

[0046] S4, subjecting the reacted product to aging, press filtration, washing, and pulping to obtain iron phosphate slurry;

[0047] S5. Add li...

Embodiment 3

[0050] A method for preparing low-cost low-temperature lithium iron phosphate, comprising the following steps:

[0051] S1, transfer the chemical chrome plating waste liquid into the filter tank with a mesh aperture of 50 orders (that is, the aperture is 150 μm) and filter to remove small particle impurities in the waste liquid;

[0052] S2, adding concentration to the chemical chrome plating waste liquid is the photochemical oxidant ozone (O 3 ), the hypophosphite and phosphite ions in the electroless chrome plating waste liquid are oxidized into orthophosphate ions, and the reaction time is 2h;

[0053] S3, in the solution treated in step S2 according to phosphate ion and Fe 3+ The molar ratio is 1.08:1, adding ferric sulfate, after stirring and mixing for 3 hours, adjust the pH value at 2.0, and react at a temperature of 60°C;

[0054] S4, subjecting the reacted product to aging, press filtration, washing, and pulping to obtain iron phosphate slurry;

[0055] S5. Add lit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com