High silica fiber reinforced reactive silsesquioxane modified hybrid phenolic aldehyde composite material and preparation method thereof

A technology of silsesquioxane and high silica fiber, which is applied in the field of hybrid phenolic composite materials and preparation, can solve the problems of high price, monopoly of synthesis methods, cumbersome purchasing routes, etc., and achieves low chemical toxicity and improved heat resistance. , the effect of suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

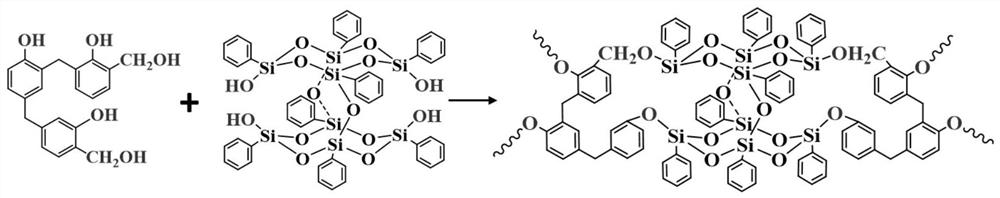

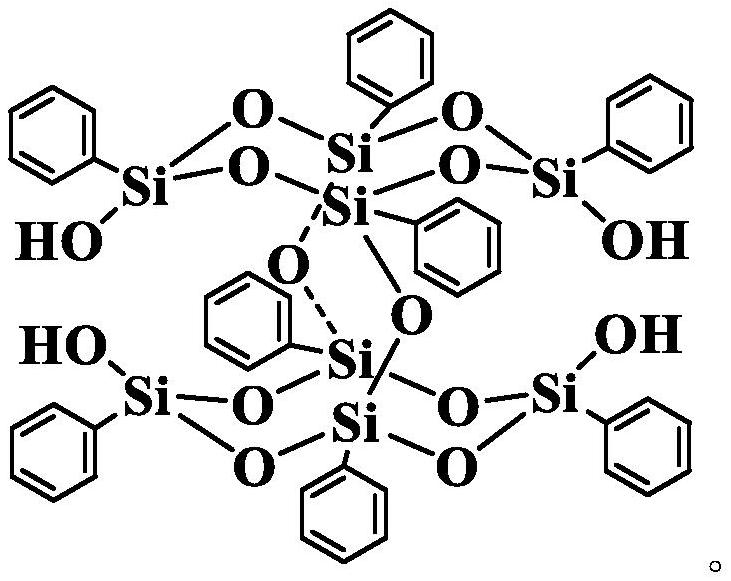

[0038] The present invention provides a method for synthesizing silsesquioxane described in the above technical scheme, comprising the following preferred steps:

[0039]In a nitrogen-protected three-necked flask equipped with a magnet and a condenser, first add isopropanol (120-150mL), then phenyltrimethoxysilane (24.0g, 121mmol), deionized water (2.5g, 139mmol ) and NaOH (3.2 g, 80 mmol) were added successively, and the mixture was reacted under reflux for 4 hours, then cooled to room temperature and reacted for 15-18 hours. After the reaction, remove most of the isopropanol with a rotary evaporator, filter to obtain a white solid, and vacuum-dry at 60° C. for 12 to 24 hours to obtain octaphenylcyclotetrasiloxane sodium tetrasilicate (DDONa) with a yield of 90 ~98%. Dissolve the above DDONa (11.6g, 10mmol) in a one-necked flask equipped with tetrahydrofuran and a magnet, add a certain amount of glacial acetic acid (3.0mL, 53mmol) and stir for 15-30 minutes, then add a certa...

Embodiment 1

[0056] In a nitrogen-protected three-necked flask equipped with a magnet and a condenser, first add isopropanol (120mL), then phenyltrimethoxysilane (24.0g, 121mmol), deionized water (2.5g, 139mmol) and NaOH (3.2 g, 80 mmol) was added successively, and the mixture was reacted under reflux for 4 hours, then cooled to room temperature and reacted for 15 hours. After the reaction was completed, most of the isopropanol was removed by a rotary evaporator, and a white solid was obtained by filtration, and vacuum-dried at 60° C. for 12 hours to obtain sodium octaphenylcyclotetrasiloxane tetrasilicate (DDONa), with a yield of 98%. Dissolve the above DDONa (11.6g, 10mmol) in a single-necked flask equipped with tetrahydrofuran and a magnet, add a certain amount of glacial acetic acid (3.0mL, 53mmol) and stir for 30 minutes, then add a certain amount of saturated sodium bicarbonate solution (10mL) to neutralize the unreacted acid, add (20mL) n-hexane to the flask, stop stirring, let stan...

Embodiment 2

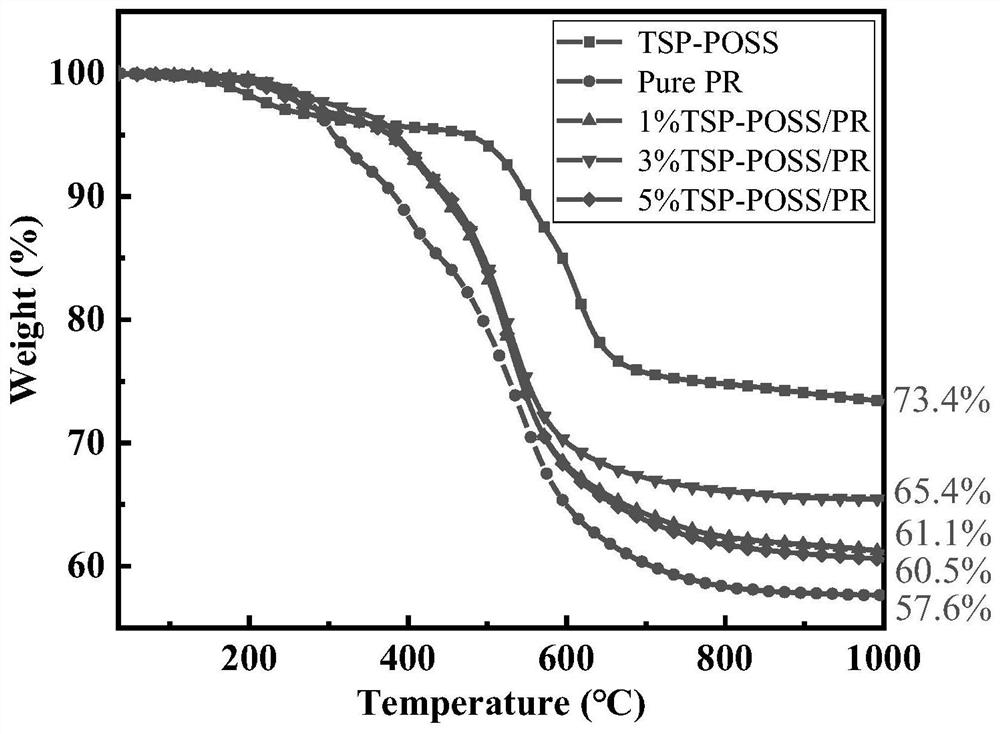

[0058] (1) Weigh 0.954g of tetrasilanol octaphenylsilsesquioxane, dissolve it in 3.816g of acetone, stir and oscillate until completely dissolved, and obtain a silsesquioxane solution with a mass fraction of 20%;

[0059] (2) Weigh 52.5g of phenolic resin solution with a solid content of 59.4%, add the above-mentioned tetrasilanol octaphenylsilsesquioxane solution into the phenolic resin solution, stir with a homogeneous stirrer for 30 minutes until uniformly mixed, Obtain a modified phenolic resin solution (silsesquioxane accounts for 3% of the total mass except the solvent);

[0060] (3) Put the modified phenolic resin into a 75°C vacuum oven to remove the solvent for 4 hours. During the solvent removal process, the vacuum should be released at any time to remove the extracted solvent;

[0061] (4) The above-mentioned modified resin after removing the solvent is directly cured in stages: 100° C. / 3 hours; 130° C. / 2 hours; 150° C. / 2 hours; 170° C. / 2 hours; natural cooling. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ablation rate | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com