Corona-resistant coating for cable and preparation method of coating

A corona resistance and coating technology, applied in polyether coatings, coatings and other directions, can solve the problems of easy aging and cracking, low corona resistance performance, poor corona resistance effect, etc., achieving good insulation, not easy to crack and aging , The effect of not easy to break down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

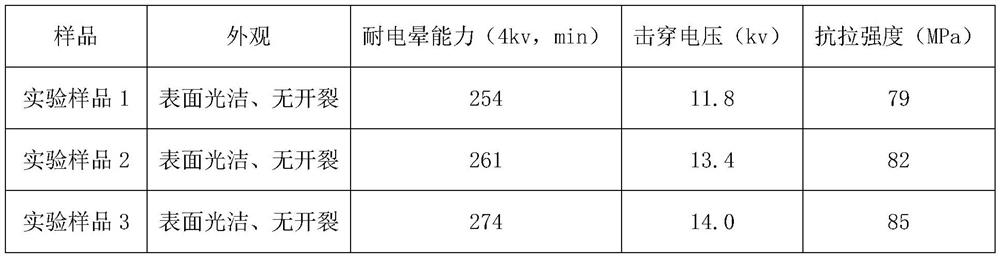

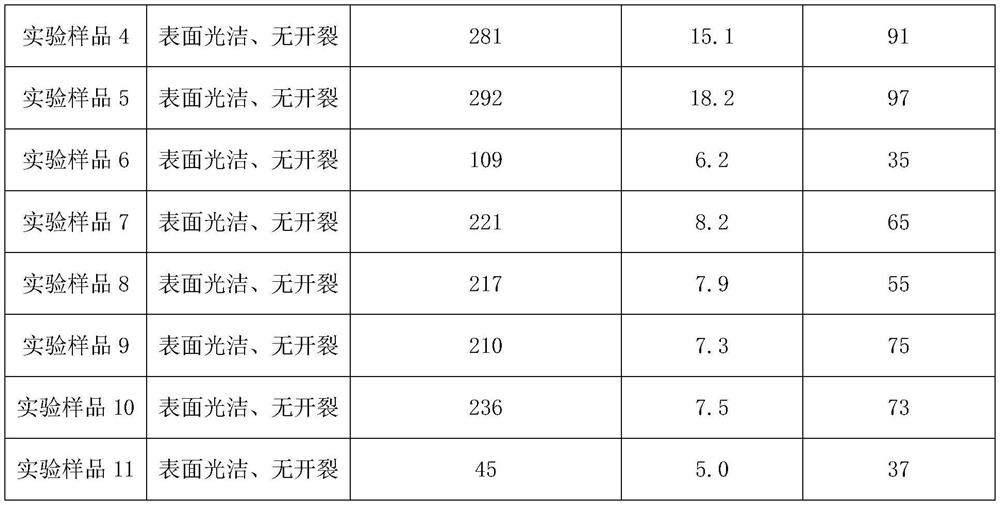

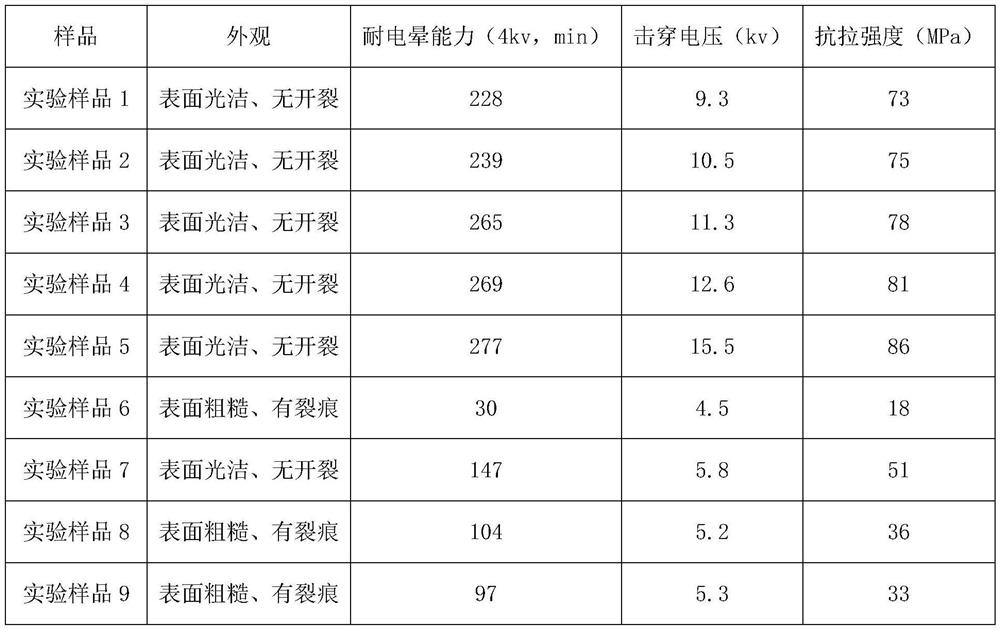

Examples

Embodiment 1

[0032] A corona-resistant coating for cables, comprising the following raw materials in parts by weight: 45 parts of acrylic resin, 500 parts of ethanol, 0.3 parts of N,N'-diisopropylcarbodiimide, 1.2 parts of perfluoropolyether, 30 parts of dried blood extract, 7 parts of mica, 2.5 parts of graphite boron nitride, 0.11 parts of benzylidene dichlorobis(tricyclohexylphosphine) ruthenium, 15 parts of porphyrin compound, 4 parts of zirconium oxide and 0.13 parts of cetyltrimethylammonium bromide.

[0033] Wherein, the porphyrin compound is porphine or tetraphenylporphyrin.

[0034] The preparation method of the dragon's blood extract is as follows: according to the weight ratio, take 5 parts of dragon's blood, add water to immerse, boil for 45 minutes, then filter, collect the filter residue to obtain the filter residue I, add 30 parts of ethanol to the filter residue I, and heat it at 80 ° C. Heating under reflux for 60 minutes, then filtering, collecting the filter residue to ...

Embodiment 2

[0044] A corona-resistant coating for cables, comprising the following raw materials in parts by weight: 65 parts of acrylic resin, 700 parts of ethanol, 1.1 parts of N,N'-diisopropylcarbodiimide, 2.4 parts of perfluoropolyether, 60 parts of dried blood extract, 19 parts of mica, 6.5 parts of graphite boron nitride, 0.23 parts of benzylidene dichlorobis(tricyclohexylphosphine) ruthenium, 23 parts of porphyrin compound, 11 parts of zirconium oxide and 0.21 parts of cetyltrimethylammonium bromide.

[0045] Among them, the porphyrin compound is 5,15-ethynylphenyl-10,20-phenylporphyrin.

[0046] The preparation method of the dragon's blood extract is as follows: according to the weight ratio, take 13 parts of dragon's blood, add water to immerse, boil for 55 minutes, then filter, collect the filter residue to obtain the filter residue I, add 80 parts of ethanol to the filter residue I, and heat it at 90°C Heating under reflux for 90 minutes, and then filtering, collecting the fil...

Embodiment 3

[0056] A corona-resistant coating for cables, comprising the following raw materials in parts by weight: 50 parts of acrylic resin, 550 parts of ethanol, 0.5 parts of N,N'-diisopropylcarbodiimide, 1.5 parts of perfluoropolyether, 40 parts of dragon's blood extract, 10 parts of mica, 3 parts of graphite-type boron nitride, 0.15 parts of benzylidene dichlorobis(tricyclohexylphosphine) ruthenium, porphyrin compound 18 parts, 6 parts of zirconia and 0.15 parts of cetyltrimethylammonium bromide; the particle size of zirconia is 50 nanometers; the molecular weight of perfluoropolyether is 3000Da.

[0057] Among them, the porphyrin compound is 5,10,15,20-tetrakis(4-ethynylphenyl)porphyrin.

[0058] The preparation method of the dragon's blood extract is as follows: according to the weight ratio, take 7 parts of dragon's blood, add water to immerse, boil for 47 minutes, then filter, collect the filter residue to obtain the filter residue I, add 38 parts of ethanol to the filter residu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com