Preparation method of isothiocyano functionalized silicon dioxide material

A silicon dioxide, isothiocyanate technology, applied in the direction of silicon dioxide, silicon oxide, nanotechnology for materials and surface science, etc., can solve the problem of low selectivity, decreased production of silicon dioxide materials, toxic and other problems, to achieve the effect of cheap and easily available raw materials, good biomedical application prospects, and good reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of isothiocyanate functionalized silica material, its preparation method comprises the steps:

[0034] 1) Preparation of Amino-modified Silica Nanoparticles

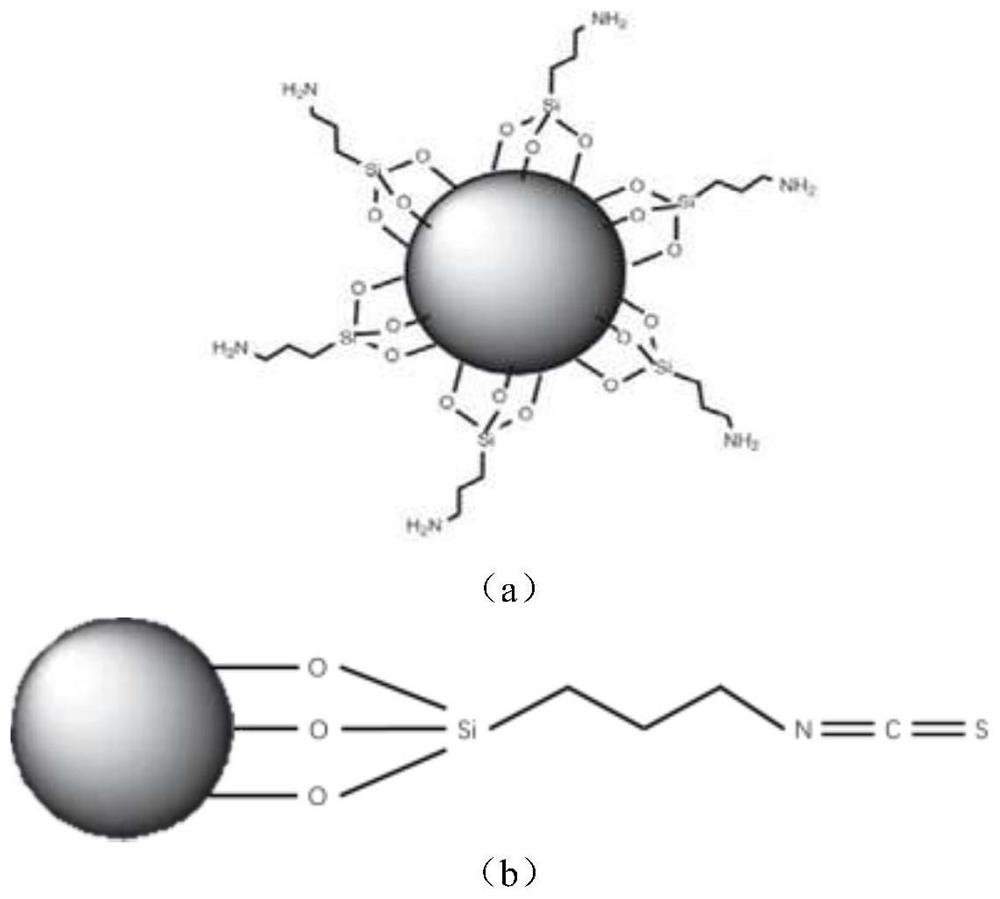

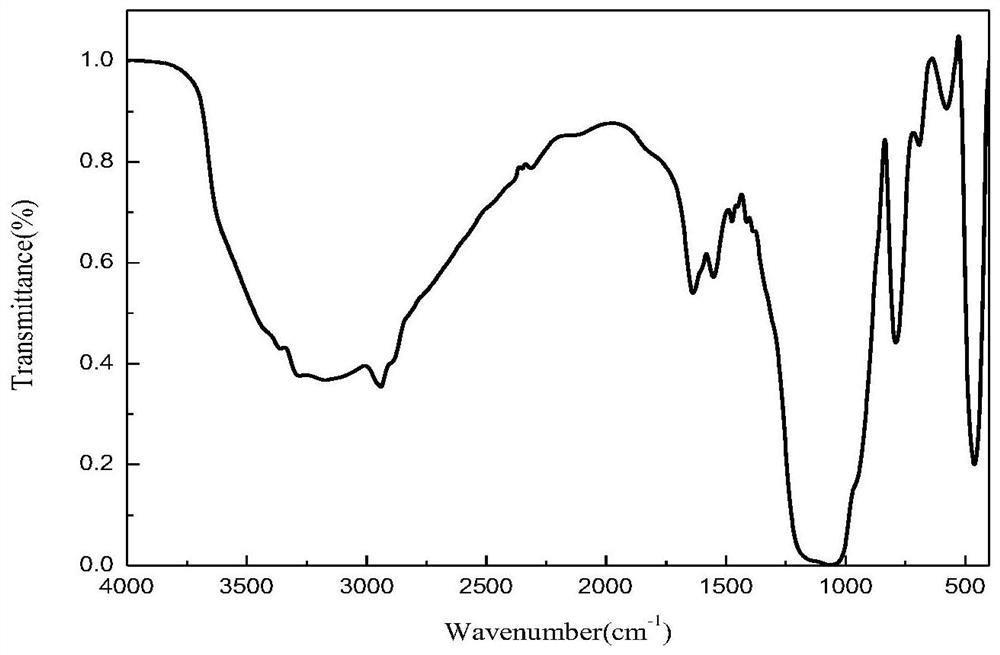

[0035] Add 7.2mL of ammonia water (25wt%) dropwise to 150mL of absolute ethanol and stir at room temperature to obtain a mixed solution I. Add 3mL of tetraethoxysilane and 1mL of 3-aminopropyltriethoxysilane into 30mL of ethanol and mix and stir for 0.5h , then poured into the mixed solution I and stirred at room temperature for 12h, concentrated the liquid with a rotary evaporator, collected by centrifugation (10000rpm, 10min), washed and dispersed with deionized water and absolute ethanol several times, dried (60°C, 12h), and obtained amino Modified silica nanoparticles (for a schematic diagram, see figure 1 a);

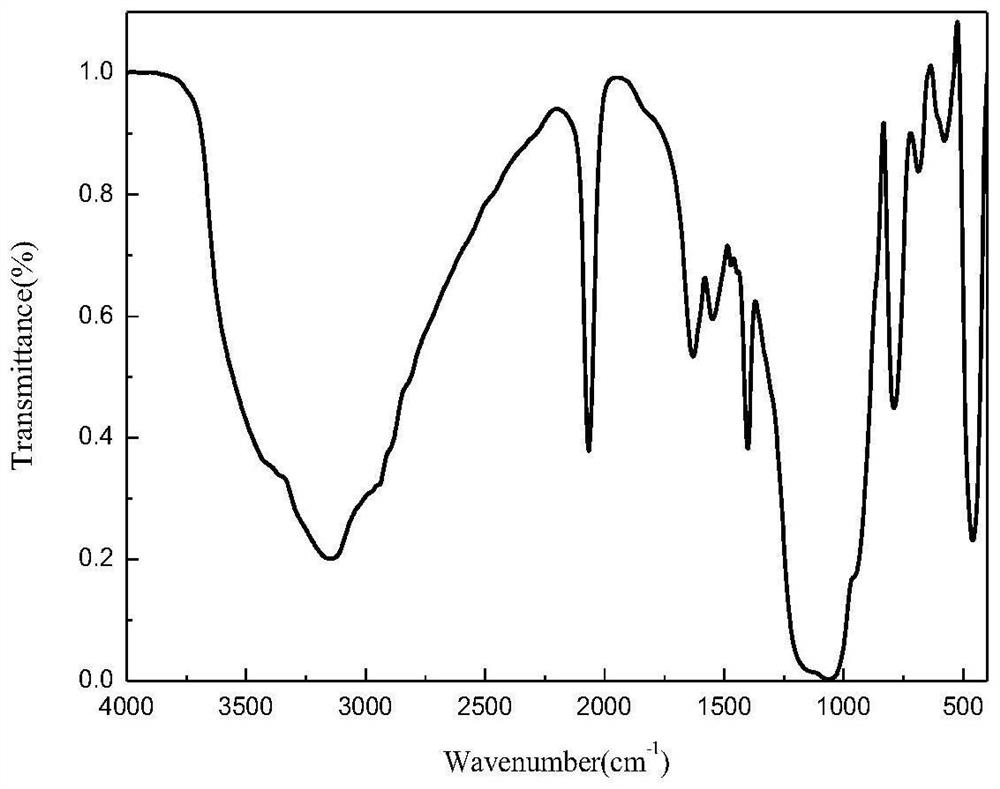

[0036] 2) Preparation of isothiocyano-functionalized silica nanoparticles

[0037] Disperse 3g of amino-modified silica nanoparticles into 50mL of absolute ethanol, add dropwise 4.0mL of am...

Embodiment 2

[0041] A kind of isothiocyanate functionalized silica material, its preparation method comprises the steps:

[0042] 1) Preparation of Amino-modified Silica Nanoparticles

[0043] Add 7.2mL of ammonia water (25wt%) dropwise to 180g of water and stir at room temperature to obtain a mixed solution I, add 1.5mL of tetraethoxysilane and 0.4mL of 3-aminopropyltrimethoxysilane into 30mL of ethanol, mix and stir for 0.5h, then pour Put it into the mixed solution I and stir at room temperature for 12h, concentrate the liquid with a rotary evaporator, collect by centrifugation (10000rpm, 10min), wash and disperse with deionized water and absolute ethanol several times, and dry (60°C, 12h) to obtain amino-modified dioxide Silicon nanoparticles;

[0044] 2) Preparation of isothiocyano-functionalized silica nanoparticles

[0045] Disperse 3g of amino-modified silica nanoparticles into 50mL of tetrahydrofuran, add 4mL of ammonia water (25wt%), stir at 15°C for 0.5h, add dropwise 1.6mL of...

Embodiment 3

[0047] A kind of isothiocyanate functionalized silica material, its preparation method comprises the steps:

[0048] 1) Preparation of Amino-modified Silica Nanoparticles

[0049] Add 7.2mL of ammonia water (25wt%) dropwise to 180g of water and stir at room temperature to obtain a mixed solution I, add 1.5mL of tetraethoxysilane and 0.4mL of 3-aminopropyltrimethoxysilane into 30mL of ethanol, mix and stir for 0.5h, then pour Put it into the mixed solution I and stir at room temperature for 12h, concentrate the liquid with a rotary evaporator, collect by centrifugation (10000rpm, 10min), wash and disperse with deionized water and absolute ethanol several times, and dry (60°C, 12h) to obtain amino-modified dioxide Silicon nanoparticles;

[0050] 2) Preparation of isothiocyano-functionalized silica nanoparticles

[0051] Disperse 3 g of amino-modified silica nanoparticles into 50 mL of tetrahydrofuran, add 3.5 mL of triethylamine, stir at 15 °C for 0.5 h, add 1.6 mL of carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com