Microporous granular carbon and its preparation method

A technology of microporous particles and carbonization, applied in separation methods, chemical instruments and methods, carbon preparation/purification, etc., can solve the problems of unpublished microsphere pore structure information, failure to observe microporous structure, etc., and achieve convenience Spherical shape and size, simple and easy-to-control preparation process, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

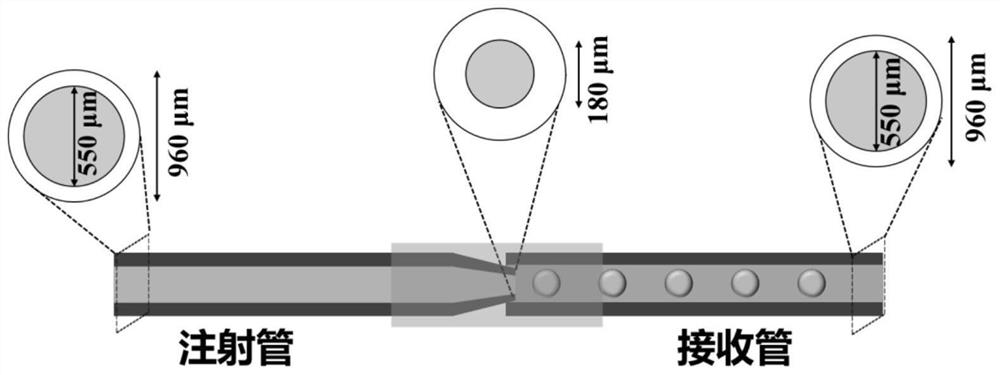

[0046] B. Preparation of monodisperse particles: Inject the internal phase solution and the external phase solution into the injection tube and collection tube of the capillary microfluidic chip to form a monodisperse water / oil emulsion, and inject the monodisperse emulsion into the curing bath to interact with the crosslinking agent. Cross-linking reaction to obtain particles;

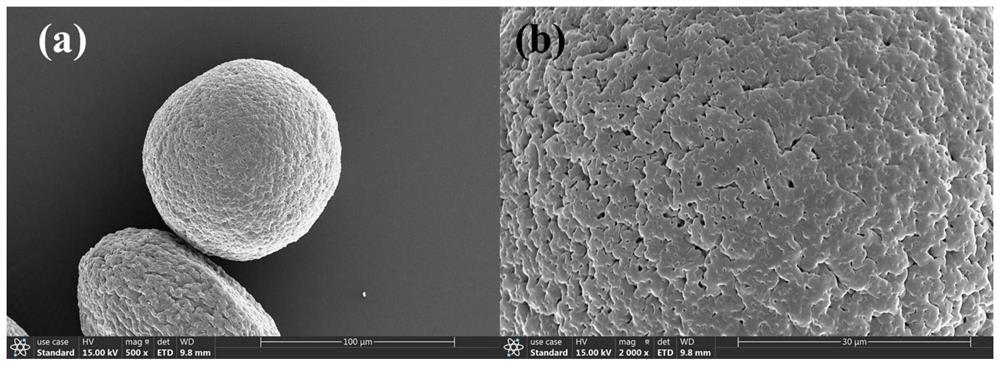

[0047] C. Cleaning, freeze-drying, and carbonization of the formed particles: separate the particles from the solidification bath, and wash them with the above-mentioned corresponding organic solvents, petroleum ether, and deionized water to remove the excess oil phase on the surface of the particles and inside the pores, and place them after drying. Carbonize in a tube furnace, heat up to a carbonization temperature of 600-900°C for carbonization to obtain microporous granular carbon, then cool down naturally, and store in a dry box.

[0048] In the method of the present invention, since chitosan is ...

Embodiment 1

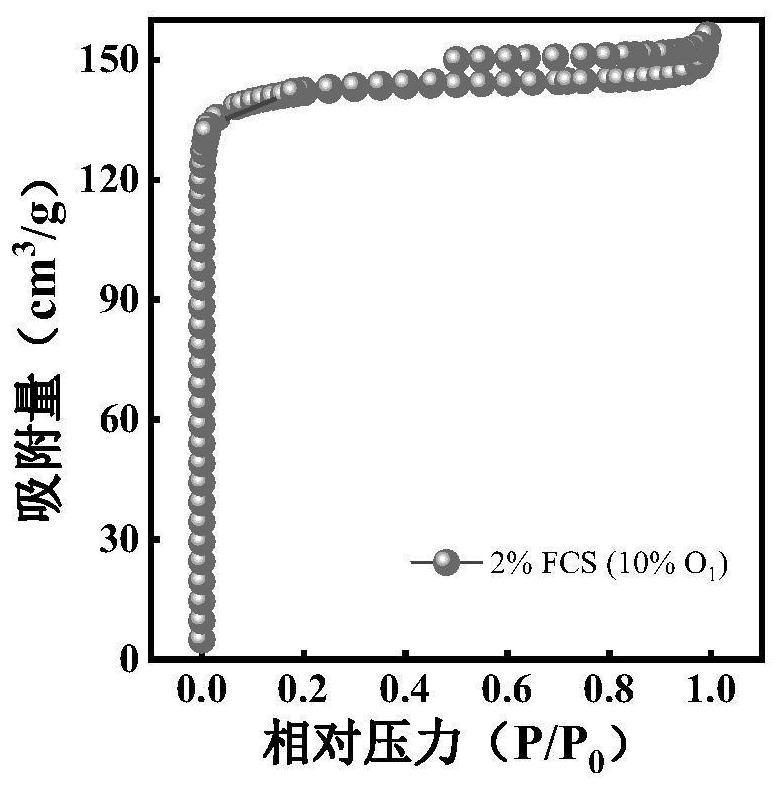

[0057] Mix 2% chitosan solution containing 2% oil-in-water emulsifier F127 with n-octane evenly, and the volume ratio of n-octane is 10%. Place it under a homogeneous emulsifier and emulsify at 13000rpm for 60s to obtain an internal phase solution. Add 6% water-in-oil emulsifier Span80 into n-octane and mix evenly to obtain the external phase solution. The curing bath is 2% cross-linking agent glutaraldehyde added to the external phase solution.

[0058] The inner phase fluid and the outer phase fluid were respectively injected into the injection tube and the collection tube of the capillary microfluidic device to form a monodisperse water / oil emulsion. The diameter of the cone tip of the injection port was 180 μm, and the diameter of the receiving tube was 550 μm. The monodisperse emulsion is injected into the solidification bath to generate crosslinking reaction with glutaraldehyde; the flow rate of the internal phase solution is 1mL / h, the flow rate of the external phase s...

Embodiment 2

[0061] Mix 2% chitosan solution containing 2% oil-in-water emulsifier F127 with n-octane evenly, and the volume ratio of n-octane is 5%. Place it under a homogeneous emulsifier and emulsify at 16000rpm for 60s to obtain an internal phase solution. Add 6% water-in-oil emulsifier Span 80 into n-octane and mix evenly to obtain the external phase solution. The curing bath is 2% cross-linking agent glutaraldehyde added to the external phase solution.

[0062] The inner phase fluid and the outer phase fluid were respectively injected into the injection tube and the collection tube of the capillary microfluidic device to form a monodisperse water / oil emulsion. The diameter of the cone tip of the injection port was 180 μm, and the diameter of the receiving tube was 550 μm. The monodisperse emulsion is injected into the solidification bath to generate crosslinking reaction with glutaraldehyde; the flow rate of the internal phase solution is 2mL / h, the flow rate of the external phase s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com