Preparation method of 3-hydroxypropanesulfonic acid

A technology of hydroxypropane sulfonic acid and sodium hydroxypropane sulfonate, which is applied in the field of preparation of 3-hydroxypropane sulfonic acid, can solve the problems of inconvenient operation, potential safety hazards, transportation, waste of energy consumption, etc., achieves reduction of acid dosage and ensures sufficient reaction , the effect of reducing the amount of acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

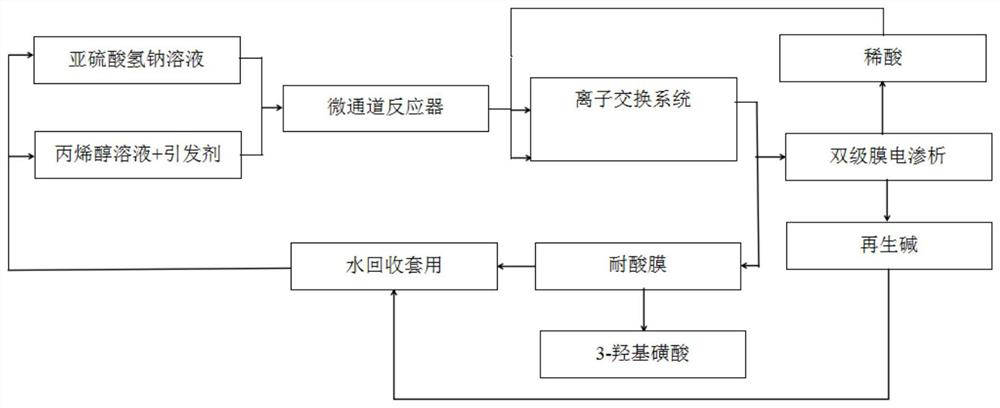

[0025] combine figure 1 , the specific embodiment proposes a kind of preparation method of 3-hydroxypropanesulfonic acid, comprises the following steps:

[0026] 1) The propenyl alcohol is mixed with the initiator and water to obtain a mixed solution, and the mixed solution and the aqueous sodium bisulfite solution are simultaneously pumped into the microchannel reactor from two inlets and heated at a pressure of 0.5-1MPa The reaction is carried out at a reaction temperature of 20-60°C to obtain the sodium 3-hydroxypropanesulfonate; wherein, the pumping speed of the mixed solution is 130-135kg / h, and the aqueous solution of sodium bisulfite The pumping speed is 80-85kg / h; The mol ratio of described propylene alcohol, sodium bisulfite and initiator is 1:(1~1.02):(0.001~0.5); Described initiator is H 2 o 2 、NaS 2 o 8 , (CH 3 ) 3 One or more of COOH and dibenzoyl peroxide. Reacting at a pressure of 0.5-1 MPa can speed up the movement speed between molecules and speed up th...

Embodiment 1

[0034] The present embodiment provides a kind of preparation method of 3-hydroxypropanesulfonic acid, comprises the steps:

[0035] (1) Add 3000kg of deionized water and 1550kg of sodium bisulfite to the 5000L enamel reactor A with mechanical stirring, stir and dissolve at room temperature;

[0036] (2) Add 2000kg deionized water, 850kg propylene alcohol and 20kg H to the 3000L enamel reactor B with mechanical stirring 2 o 2 , stir evenly at room temperature;

[0037] (3) Through the metering pump, pump the liquid in the A kettle at 130kg / h, and the solution in the B kettle at 80kg / h, and simultaneously pump them into the microchannel reactor for reaction. The reaction temperature is 50°C, and the discharge back pressure valve is adjusted to make the system The pressure reaches 0.5MPa;

[0038] (4) The reaction solution passes through the A column activated by the separation system. After the A column resin is saturated with sodium ions, switch to the B column. At this time...

Embodiment 2

[0042] The present embodiment provides a kind of preparation method of 3-hydroxypropanesulfonic acid, comprises the steps:

[0043](1) Add 3000kg of deionized water and 1560kg of sodium bisulfite to the 5000L enamel reactor A with mechanical stirring, stir and dissolve at room temperature;

[0044] (2) Add 2000kg deionized water, 860kg propylene alcohol and 25kg NaS to the 3000L enamel reactor B with mechanical stirring 2 o 8 , stir evenly at room temperature;

[0045] (3) Through the metering pump, pump the liquid in the A kettle at 135kg / h, and the solution in the B kettle at 82kg / h, and simultaneously pump them into the microchannel reactor for reaction. The reaction temperature is 20°C, and the discharge back pressure valve is adjusted to make the system The pressure reaches 1MPa;

[0046] (4) The reaction solution passes through the A column activated by the separation system. After the A column resin is saturated with sodium ions, switch to the B column. At this time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com