Cellulose acetate nano composite material with ultraviolet shielding and bacteriostatic properties and preparation method thereof

A nano-composite material, cellulose acetate technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, can solve the problems of cellulose acetate antibacterial and UV shielding limitations, and achieve excellent UV shielding performance , low hygroscopicity, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

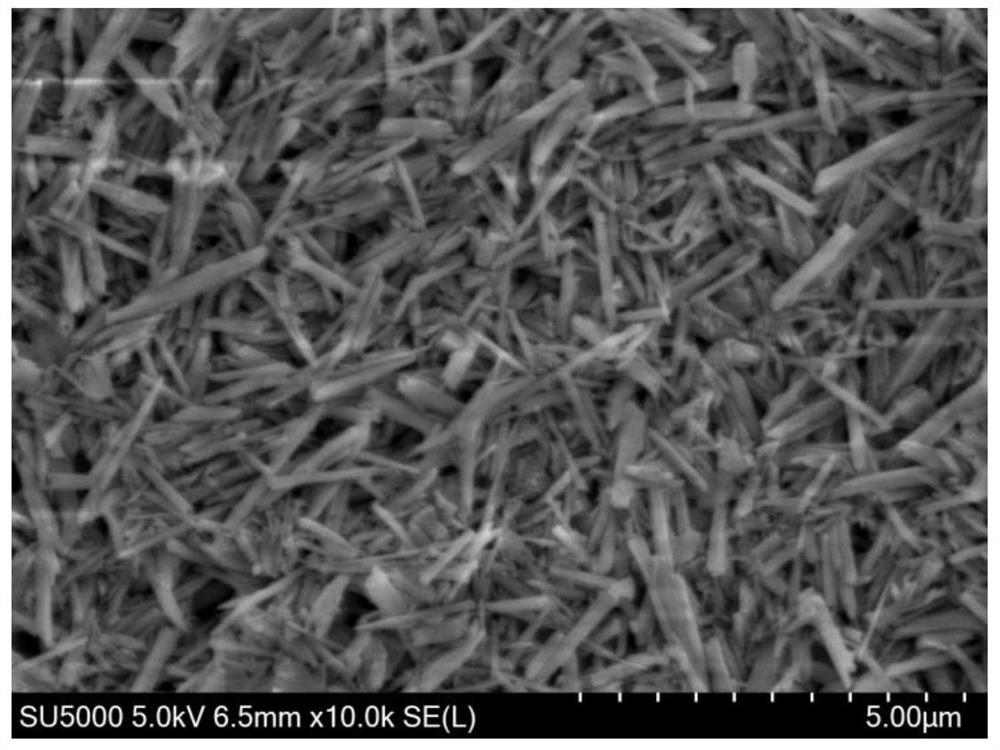

[0021] The halloysite modified by the copper complex is a self-made nano particle (diameter is 40-80nm, length is 200-1000nm), and its preparation method comprises the following steps:

[0022] Add halloysite into deionized water at room temperature, stir for 30 minutes and mix well, then add copper chloride dihydrate, stir for 2 hours to obtain a uniform dispersion; then dissolve 1,2-benzisothiazol-3-one into DMF, and the resulting 1,2-benzisothiazol-3-one solution was added to the above dispersion, stirred for 30 minutes, placed in a constant temperature water bath at 70°C for 24 hours, and then centrifuged , washing and drying to obtain the halloysite modified by the copper complex;

[0023] The mass ratio of halloysite, deionized water, copper chloride dihydrate, 1,2-benzisothiazol-3-one and DMF is 5:250:2:1.7:250.

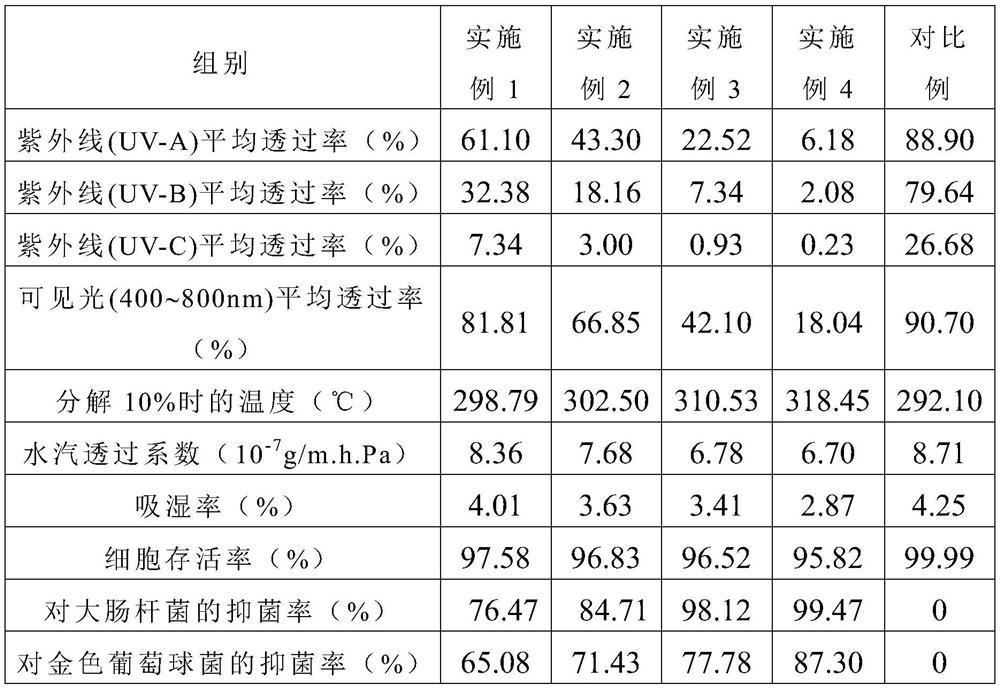

Embodiment 1

[0025] A cellulose acetate nanocomposite material with ultraviolet shielding and bacteriostasis properties consists of the following components by weight: 99.5 parts of cellulose acetate and 0.5 parts of halloysite modified by copper complexes.

[0026] The preparation method comprises the steps of:

[0027] (1) Disperse 0.5 part of halloysite modified by copper complex in 2000 parts of acetone, sonicate at room temperature for 1 h, and stir for 1 h to obtain a uniform dispersion of halloysite modified by copper complex, which is set aside;

[0028] (2) 99.5 parts of cellulose acetate are added to the halloysite homogeneous dispersion modified by the copper complex obtained in step (1), stirred at room temperature for 4 hours, and ultrasonically removed to obtain a uniform film-forming liquid for subsequent use;

[0029] (3) The film-forming solution obtained in step (2) was poured into a flat-bottomed glass dish, and dried in a vacuum oven at 35° C. for 24 hours to obtain a c...

Embodiment 2

[0031] A cellulose acetate nanocomposite material with ultraviolet shielding and bacteriostasis properties consists of the following components in parts by weight: 99 parts of cellulose acetate and 1.0 part of halloysite modified by copper complexes.

[0032] The preparation method comprises the steps of:

[0033] (1) Disperse 1.0 part of halloysite modified by copper complex in 2000 parts of acetone, sonicate at room temperature for 1 h, and stir for 1 h to obtain a uniform dispersion of halloysite modified by copper complex, which is set aside;

[0034] (2) 99 parts of cellulose acetate are added to the halloysite homogeneous dispersion modified by the copper complex obtained in step (1), stirred at room temperature for 4 hours, and ultrasonically removed to obtain a uniform film-forming liquid for subsequent use;

[0035] (3) The film-forming solution obtained in step (2) was poured into a flat-bottomed glass dish, and dried in a vacuum oven at 35° C. for 24 hours to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com