A kind of butadiene rubber micro-nano fiber based on solution jet spinning method

A technology of micro-nano fiber and cis-butadiene rubber, which is applied in the directions of drawing spinning, spinning solution preparation, fiber chemical characteristics, etc., can solve problems such as breakage and discontinuous spinning process, and achieve flexible production operation and low equipment cost. , good controllability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of preparation method based on the butadiene rubber micro-nano fiber of solution jet spinning method, comprises the steps:

[0047] 0.6g (100 parts) butadiene rubber was added in 9.4g tetrahydrofuran, stirred at room temperature (stirring speed is 400r / m) 24 hours to obtain butadiene rubber solution (concentration is 6%); Then in butadiene rubber solution Add 0.072 g (12 parts) of 2-methyl-1-(4-methylthiophenyl)-2-morpholinyl-1-propanone and 0.072 g (12 parts) of trimethylolpropane tris(3-mercapto Propionate) was stirred at room temperature for 4 hours, and finally left to stand at room temperature for 12 hours for degassing to obtain a homogeneously mixed butadiene rubber spinning solution.

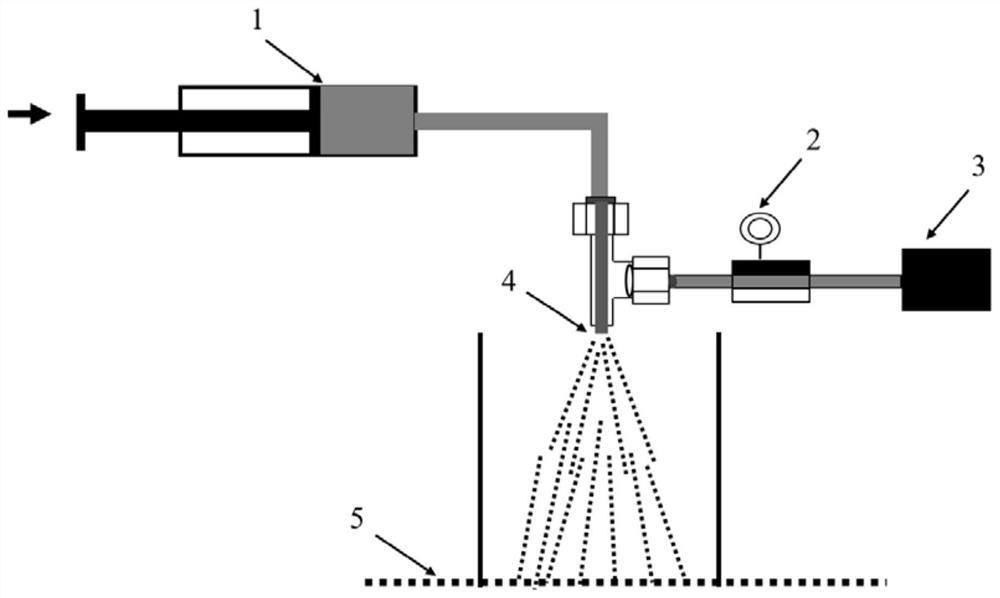

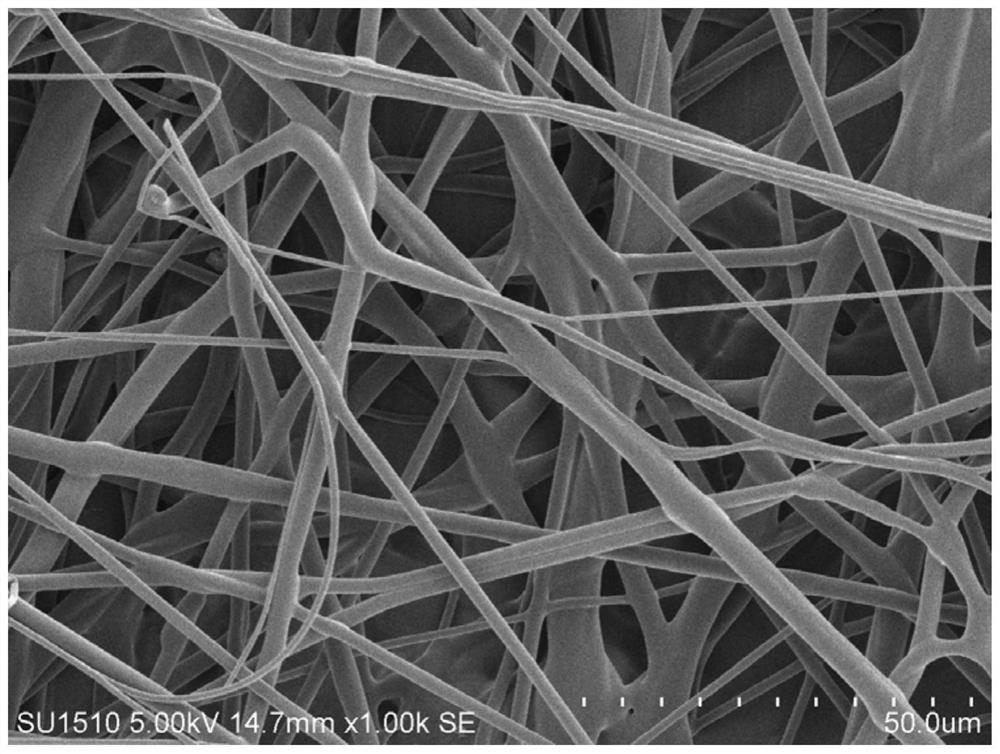

[0048] The obtained butadiene rubber spinning solution is jet-spun, and the extrusion rate of the solution is set to be 1.2mL / h, the diameter of the spinneret is 0.4mm, the distance between the spinneret and the receiving device is 15cm, and the drafting wind pressure is 0.4M...

Embodiment 2

[0050] A kind of preparation method based on the butadiene rubber micro-nano fiber of solution jet spinning method, comprises the steps:

[0051] Add 0.6g (100 parts) of butadiene rubber to 9.4g of tetrahydrofuran, stir at room temperature (stirring speed is 400r / m) for 24 hours to obtain a butadiene rubber solution; then add 0.048g (8 parts) to the solution) 2-Methyl-1-(4-methylthiophenyl)-2-morpholino-1-propanone and 0.048 g (8 parts) of trimethylolpropane tris(3-mercaptopropionate) at room temperature Stirring at low temperature for 4 hours, and finally standing at room temperature for 12 hours for defoaming, to obtain a homogeneously mixed butadiene rubber spinning solution.

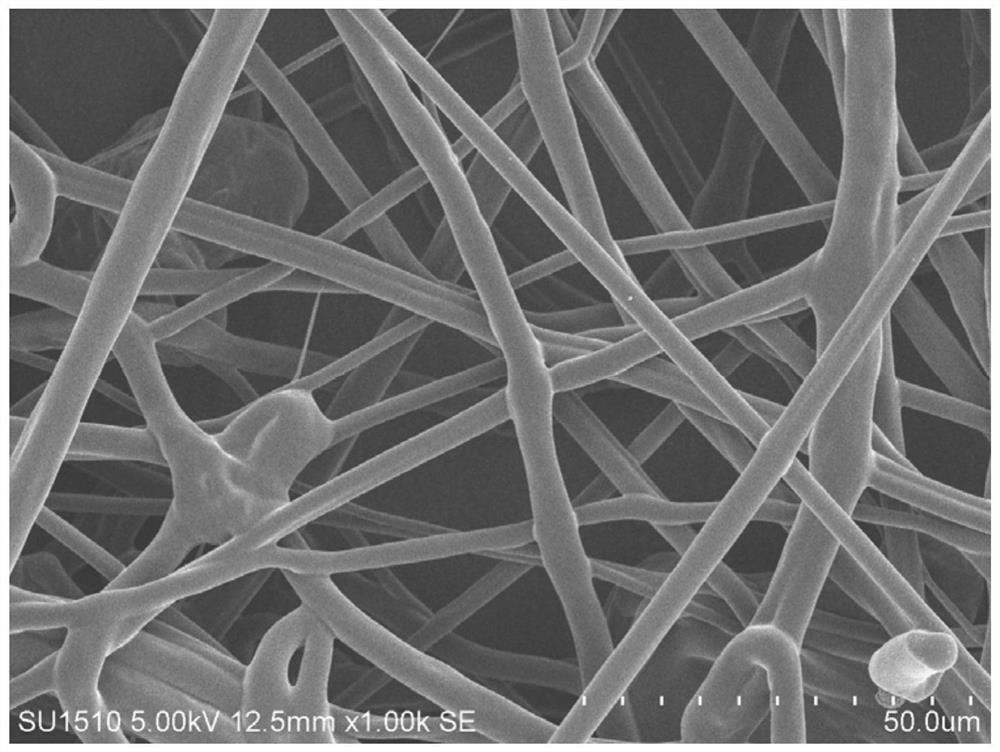

[0052] The obtained butadiene rubber spinning solution is jet-spun, and the extrusion rate of the solution is set to be 1.2mL / h, the diameter of the spinneret is 0.5mm, the distance between the spinneret and the receiving device is 20cm, and the drafting wind pressure is 0.4MPa , the spinning enviro...

Embodiment 3

[0054] A kind of preparation method based on the butadiene rubber micro-nano fiber of solution jet spinning method, comprises the steps:

[0055] 0.7g (100 parts) of butadiene rubber was added to 9.3g of tetrahydrofuran, and stirred at room temperature (stirring speed was 400r / m) for 24 hours to obtain a butadiene rubber solution; then 0.084g (12 parts) of 2 -Methyl-1-(4-methylthiophenyl)-2-morpholino-1-propanone and 0.056 g (8 parts) of trimethylolpropane tris(3-mercaptopropionate) at room temperature Stir for 4 hours, and finally stand at room temperature for 12 hours for defoaming to obtain a homogeneously mixed butadiene rubber spinning solution.

[0056] The obtained butadiene rubber spinning solution is jet-spun, and the extrusion rate of the solution is set to be 1.2mL / h, the diameter of the spinneret is 0.5mm, the distance between the spinneret and the receiving device is 15cm, and the drafting wind pressure is 0.4MPa , the spinning environment temperature is 30°C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com