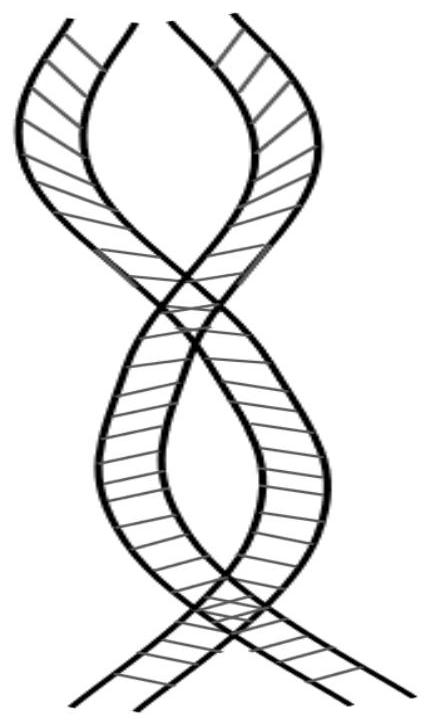

Fibrous lithium ion battery with double-helix structure and preparation method and device thereof

A technology of double helix structure, lithium ion battery, applied in electrolyte battery manufacturing, fiber processing, secondary battery, etc., can solve the problems of small effective contact area, complicated preparation process, low lithium ion transmission rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

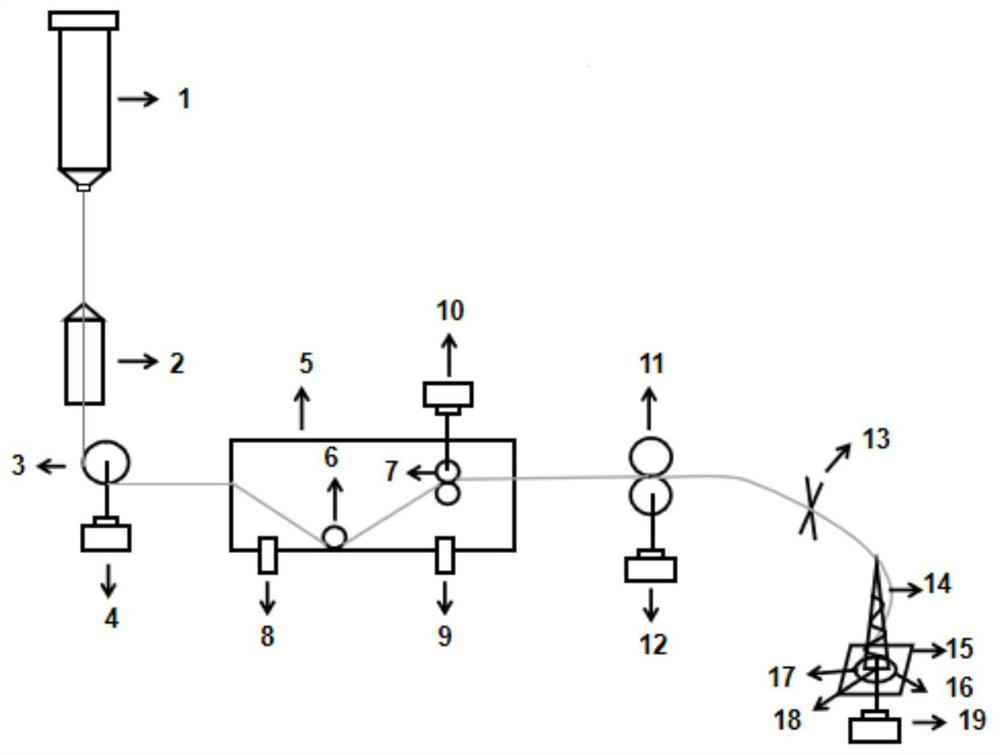

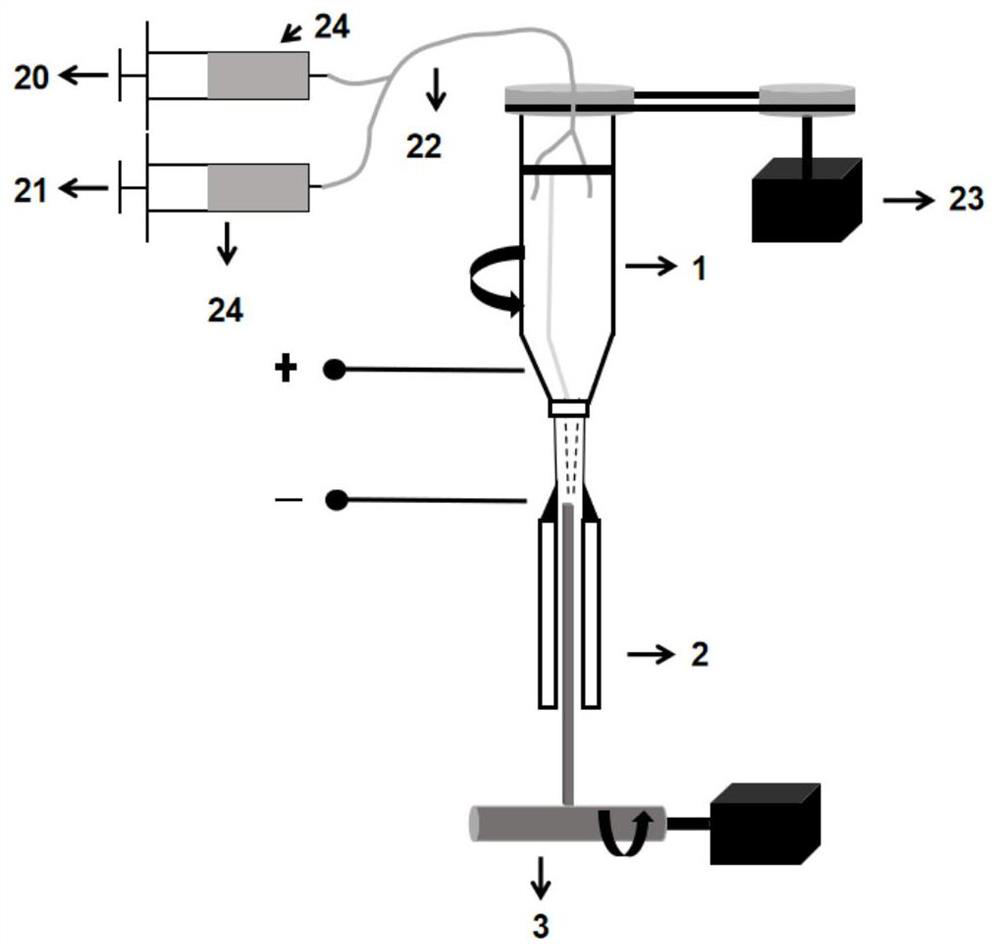

[0077] A device for preparing double helical fibrous lithium-ion batteries, such as Figure 1~2 As shown, it includes a spinning assembly, a hollow conical metal tube 2 and a post-processing device;

[0078] The spinning assembly includes a liquid supply device and an eccentric injection device 1 .

[0079] The liquid supply device 24 includes a dual-channel transfusion tube 22; the dual-channel transfusion tube is respectively equipped with a spinning solution A 20 and a spinning solution B 21;

[0080] The eccentric injection device includes a hollow cylinder I, a hollow circular platform and a hollow cylinder II connected in sequence. The diameter of the bottom surface of the hollow cylinder I is larger than that of the hollow cylinder II; Two independent channels, two independent channels communicate with the double spinnerets respectively, the double spinnerets are connected side by side, the shape of the spinnerets is rectangular, and the eccentric injection device can ...

Embodiment 2

[0089] A preparation method of a double helix structure fibrous lithium ion battery, comprising the steps of:

[0090] (1) Configure spinning solution A: first dissolve polymer I (a mixture of PVA and PC with a mass ratio of 3:1) in a solvent (water) at 80°C, stir until a uniform and transparent solution is formed, and then LiCoO 2 Uniformly dispersed in a transparent solution and stirred to form a uniform transparent sol to obtain spinning solution A; in spinning solution A, the mass concentration of polymer I is 1.5g / 10mL; LiCoO 2 And the mass ratio of polymer I is 3:1;

[0091] Configuration of spinning solution B: first dissolve polymer II (PAN) in solvent (DMF) to form a uniform transparent solution, then add nano-silica powder and evenly disperse in the transparent solution to obtain spinning solution B; in spinning solution B, The mass percent of polymer II is 8wt%; The mass ratio of nano silicon powder and polymer II is 1:1;

[0092] (2) The device of Example 1 is us...

Embodiment 3

[0103] A preparation method of a double helix structure fibrous lithium ion battery, comprising the steps of:

[0104] (1) Configuration of spinning solution A: first dissolve polymer I (a mixture of PEG and PC with a mass ratio of 3:1) in a solvent (water) at 90°C, stir until a uniform and transparent solution is formed, and then LiCoO 2 Uniformly dispersed in a transparent solution and stirred to form a uniform transparent sol to obtain spinning solution A; in spinning solution A, the mass concentration of polymer I is 2g / 10mL; LiCoO 2 And the mass ratio of polymer I is 3:1;

[0105] Configuration of spinning solution B: first dissolve the polymer II (PVP) in a solvent (a mixture of ethanol and water with a volume ratio of 3:1) to form a uniform transparent solution, and then add nano-silica powder and evenly disperse in the transparent solution to obtain Spinning solution B; in spinning solution B, the mass percent of polymer II is 12wt%; The mass ratio of nano silicon pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com