Method for improving injectivity of oil-displacing polymer

An oil-displacing polymer and injectable technology, applied in drilling compositions, chemical instruments and methods, and earth-moving drilling, etc., can solve the problems of reducing polymer adsorption, weak adsorption force, poor stability, etc., and achieve stable adsorption. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

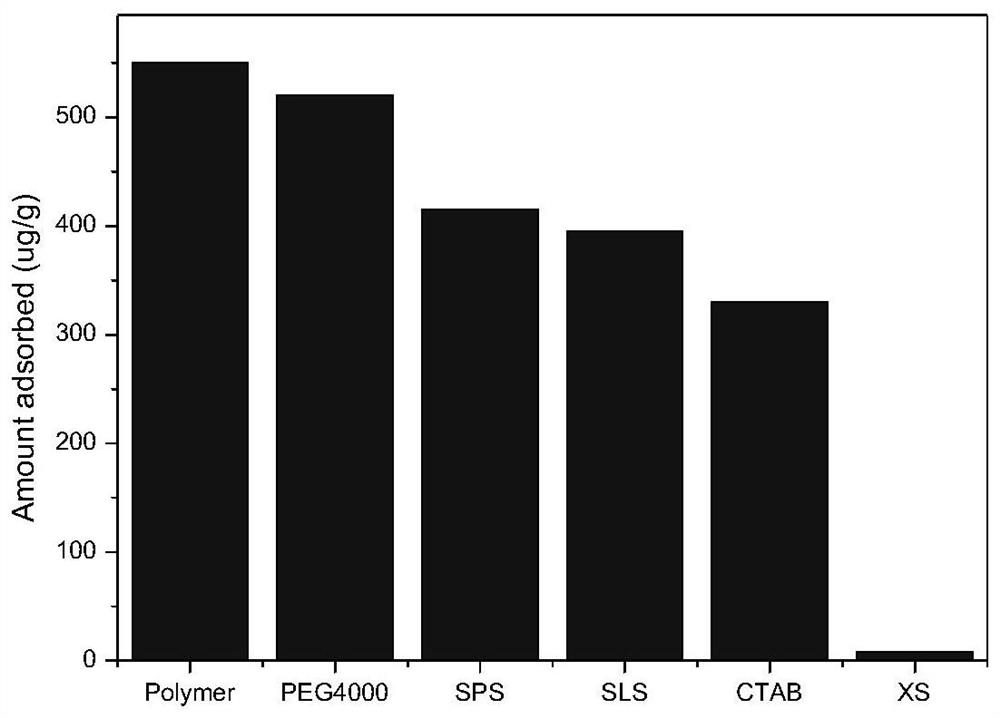

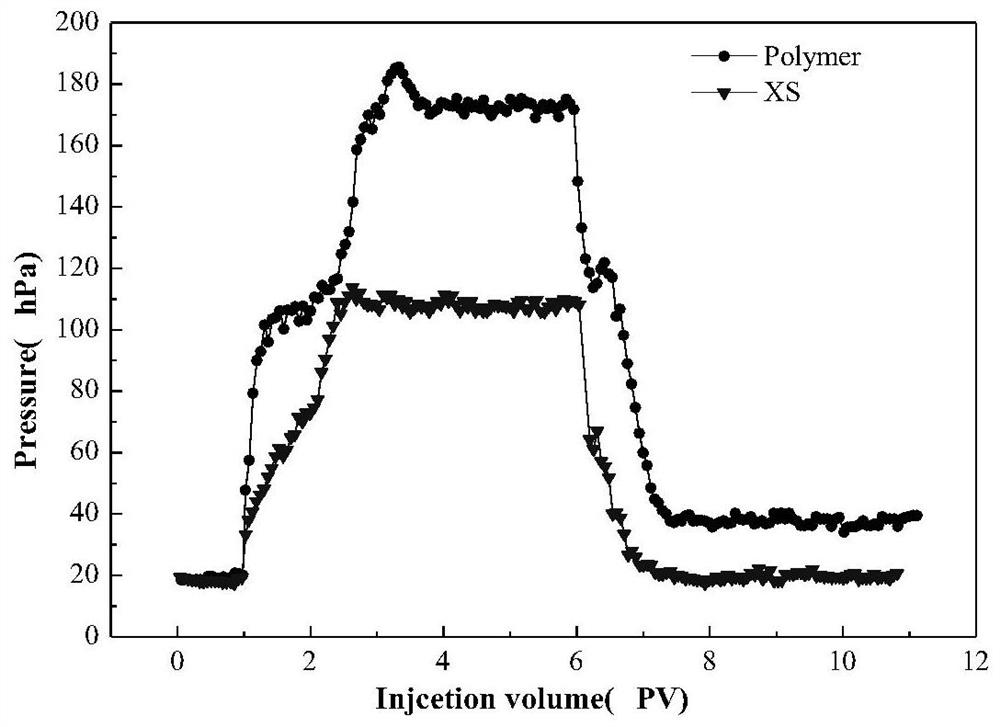

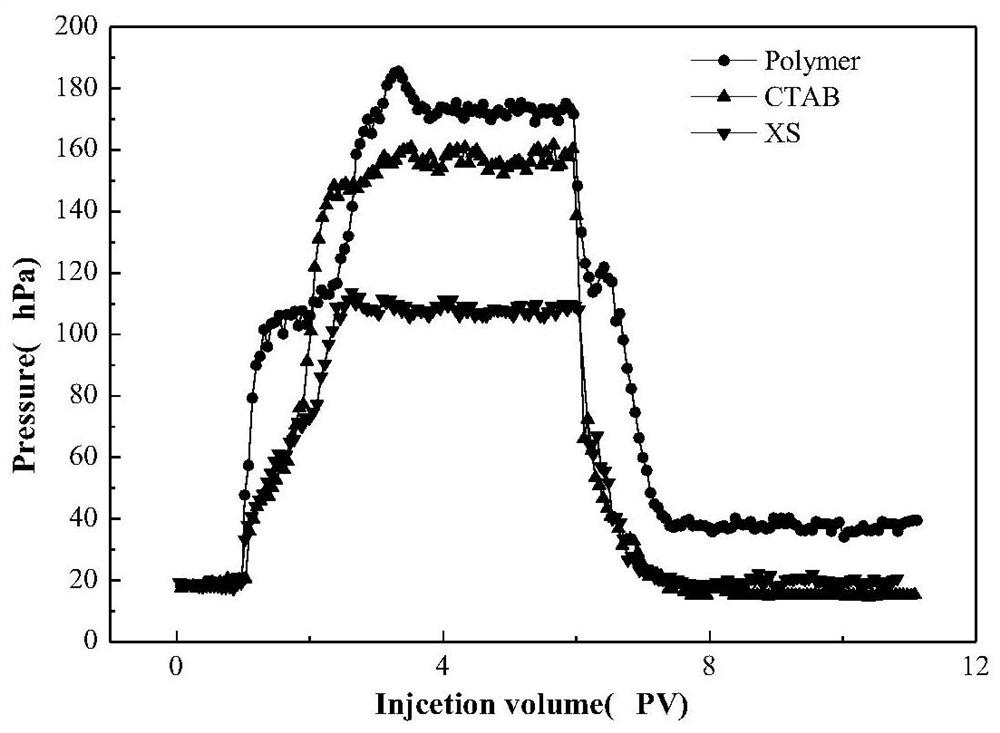

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0032] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0033] 1. Preparation of chemical injection system

[0034] The organosilicon sacrificial agent used in this embodiment is triethoxyoctylsilane, and the auxiliary agent is a mixture of N-methyldiethanolamine and petroleum sulfonate. In the auxiliary agent, the mass percent concentration of N-methyldiethanolamine is 90%, the mass percent concentration of petroleum sulfonate is 10%. Compound the organosilicon sacrificial agent and the auxiliary agent according to the mass ratio of 70:30. The specific steps are: first prepare the aqueous solution of the auxiliary agent, wherein the mass fraction of N-methyldiethanolamine is 9%, the mass fraction of petroleum sulfonate The fraction is 1%, and then triethoxyoctylsilane is added to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com