High-performance radial tire tread base rubber and preparation method thereof

A radial tire and tread base technology, applied in the field of tire rubber, can solve problems such as easy aging, BIR micro-block or block chain link distribution is not obvious, carcass cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

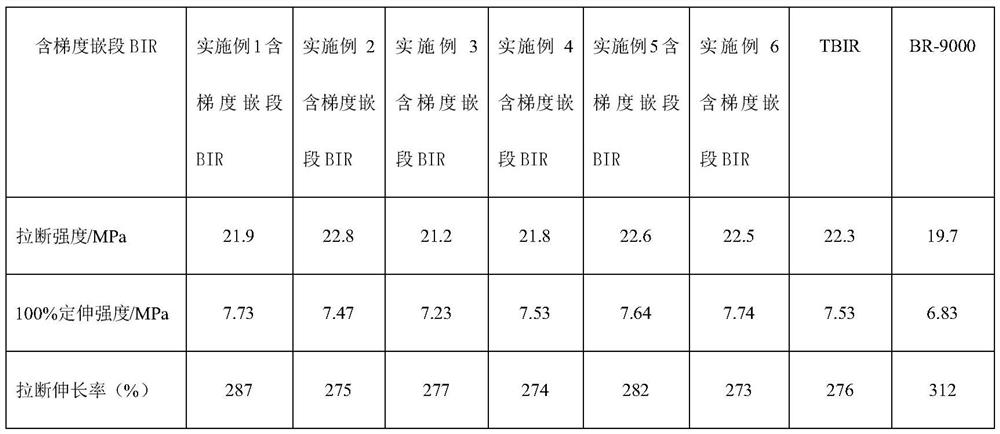

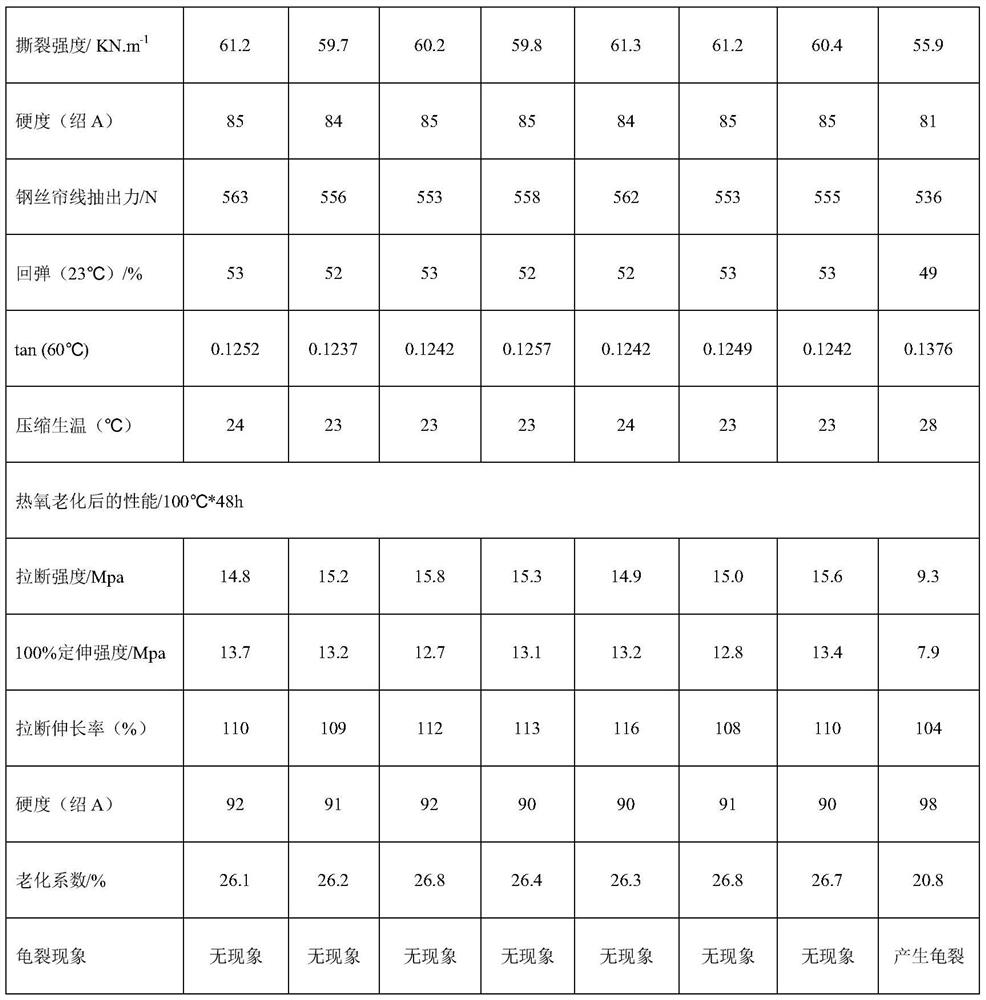

Examples

Embodiment 1

[0072] Add 7000mL of n-hexane and 1.0mL of 1.5-diazobicyclo[4,3,0]-5-nonene (DBN) into a 10-liter polymerization kettle under nitrogen protection, and then add it to the polymerization kettle under nitrogen pressure. 1060g of butadiene and 300g of isoprene, start stirring, then raise the temperature of the polymerization solution to 75°C, nitrogen protection pressure 0.35Mpa, then add 0.72mol / L NBL 13.5mL, then drop 9.5 One mmol of DVB dilute solution in hexane is added dropwise for 45 minutes. At this time, the temperature of the glue solution rises to the highest temperature of 95.6°C after 45 minutes of polymerization reaction, and the temperature rise rate is 0.46°C / min. Then continue to stir and react for 20 minutes, then add 13 mL of 0.7 mol / L N,N’-dimethylimidazolinone to the polymerization kettle, and react at a temperature not higher than 90°C for 15-20 minutes.

[0073] Then, the polymer glue was removed from the polymerization kettle, and 3.5g of antioxidant 1076 wa...

Embodiment 2

[0076] Keep the relevant process conditions in Example 1 unchanged, only 0.9mL of DBN is added, the mixed monomer used in the first stage is composed of 1100g of butadiene and 350g of isoprene, and the added butyllithium is 12mL 10.8mmol of divinylbenzene for continuous dropping, and the continuous dropping time is 50min; 12mL of N,N'-dimethylimidazolidinone for lithium termination of the second active chain.

[0077] The results are measured: the number average molecular weight Mn=16.78×10 of raw rubber 4 , the molecular weight distribution index is 2.74; the 1,2-addition unit content in the polybutadiene unit in the raw rubber is 8.43%, and the trans 1,4-addition unit content is 78.56%; the polyisoprene unit in the The 3,4-addition unit content is 6.42%, and the trans 1,4-addition unit content is 81.86%. The Mooney viscosity ML of the raw rubber is 58.5; the Tg is -84.6°C.

Embodiment 3

[0079]Keep the relevant process conditions in Example 2 unchanged, only 1.2mL of DBU is added, the mixed monomer used in the first stage is composed of 900g of butadiene and 500g of isoprene, and the added butyllithium is 10mL 11.8 mmol of divinylbenzene for continuous dropwise addition, and the continuous dropwise addition time is 48 minutes. 10mL of N,N'-dimethylimidazolidinone used for the lithium termination of the second active chain was reacted at 85-90°C for 20min, and then 0.7mol / L of tributyltin chloride was added to the polymerization kettle. After reacting 9mL of hexane solution at 80-85°C for 20min, it is ready.

[0080] The results are measured: the number average molecular weight Mn=19.24×10 of raw rubber 4 , molecular weight distribution index 2.86; 1,2-addition unit content in polybutadiene unit in raw rubber is 7.46%, trans 1,4-addition unit content is 78.94%; polyisoprene unit 3 , The content of 4-addition units is 6.23%, and the content of trans-1,4-additi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com