Air pulse air-permeability improvement biomass fermentation apparatus and method

A technology of biomass fermentation and fermentation method, which is applied in the field of gas pulse anti-permeability biomass fermentation devices, can solve the problems of high production cost, inability to realize in-situ loose pile operation, manual management, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

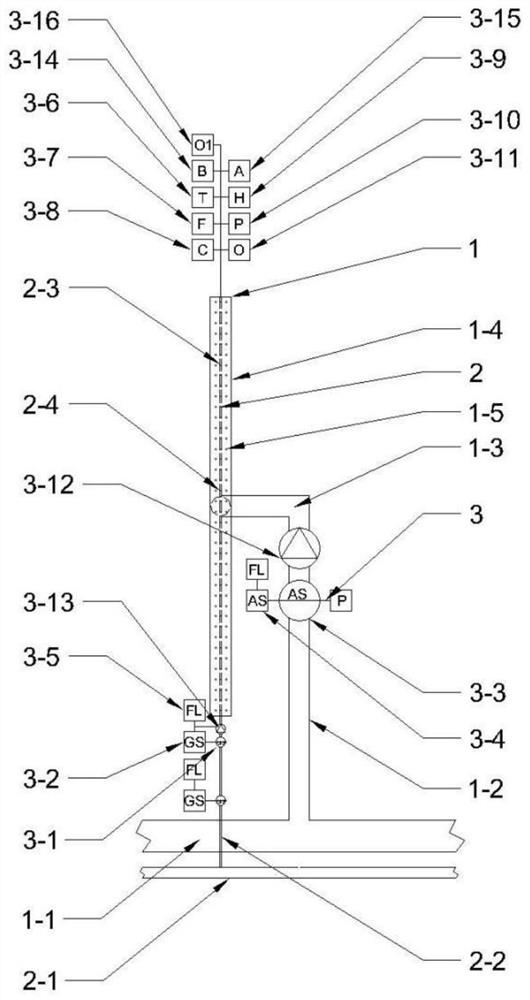

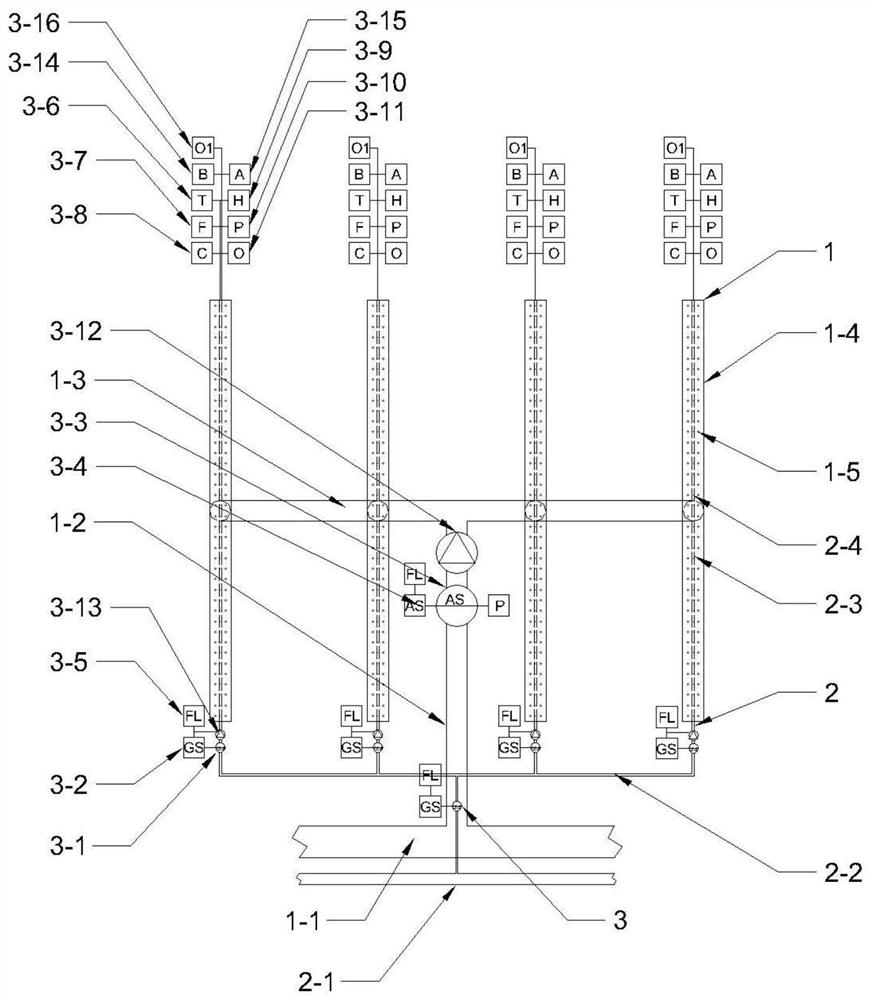

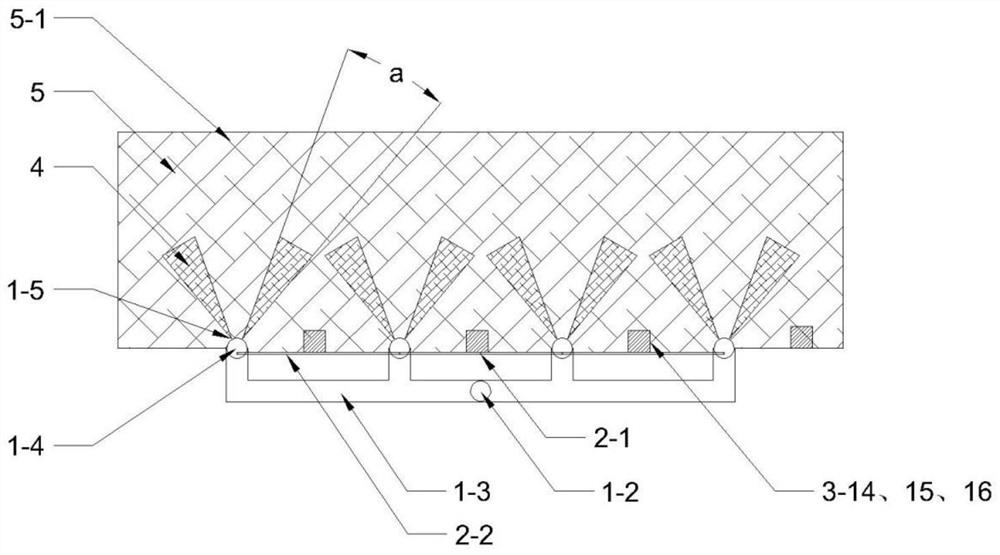

[0052] A gas pulse anti-reflection biomass fermentation device of the present invention is composed of one or more groups of pulsating air supply system 1, methane supply system 2 and automatic control system 3. It is an independent unit structure or a parallel unit structure. According to actual needs, a Group independent unit structures such as figure 1 shown; or set two, three, four or more parallel unit structures. figure 2 It is a four-group parallel unit structure. The pulsating air supply system 1 of each group communicates with the methane supply system 2 respectively, and is positioned at the bottom of the overlying stack body 5, such as image 3 As shown, the air jet is carried out to the overlying stack body 5 through the air jet hole to form a gas jet area 4 with an angle α of 10-20°; the automatic control system 3 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com