Preparation method of a hydrogel flexible strain sensor

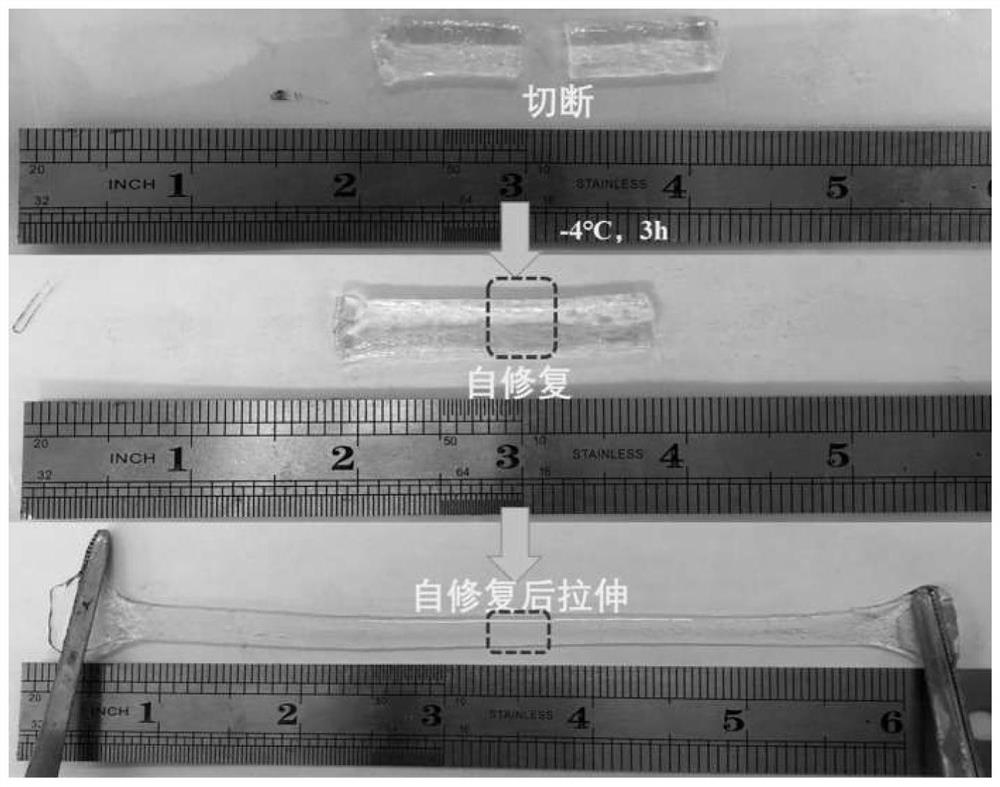

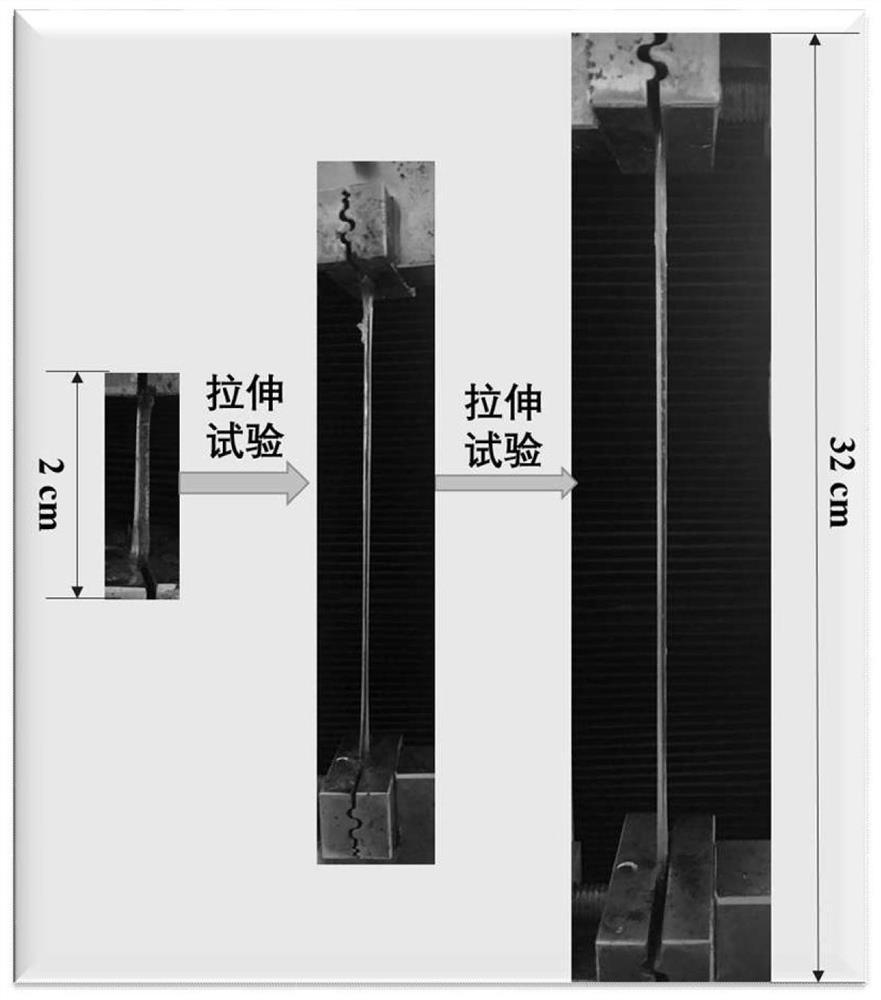

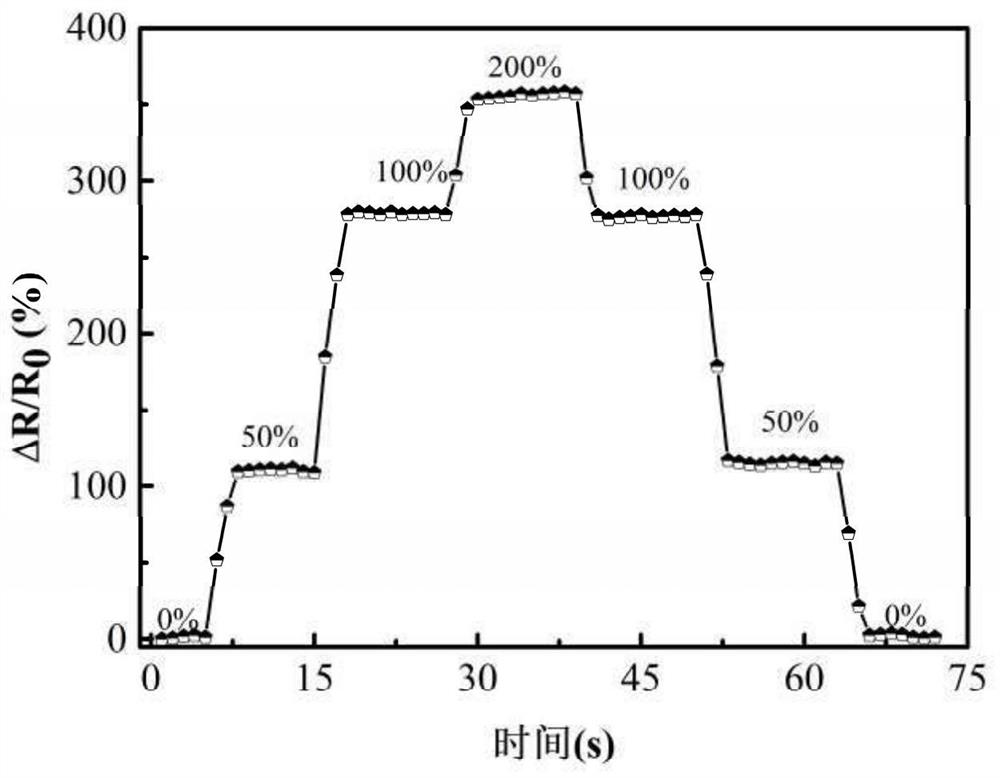

A strain sensor, hydrogel flexible technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of sensor performance degradation, breaking or bending, plastic deformation, etc., and achieve wide linear detection range and response speed Fast and excellent dynamic durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Fabrication of hydrogel flexible strain sensors:

[0036] (1) Choline chloride and urea were mixed in a molar ratio of 1:1 and placed in a flask, and magnetically stirred in an oil bath at 60° C. for 2 hours to form a clear deep eutectic solvent for later use.

[0037] (2) Add 20 mL DMSO to the above 10 mL deep eutectic solvent and continue stirring for 30 min. Subsequently, 0.5 g of polyvinyl alcohol was added and stirred, and 1 mL of cellulose nanocrystal solution and 1 mL of graphitic carbon nitride solution were added, and the stirring was continued for 5 h.

[0038] (3) Pour the material obtained in step (2) into a petri dish, place it in the refrigerator, and freeze it at -20°C for 20 hours to freeze and polymerize to form a polyvinyl alcohol network. Take it out and place it at room temperature for 2 hours before placing it in the refrigerator. Store at 20°C for 6 hours to obtain a hydrogel.

[0039] (3) Clean and dry the above hydrogel, install conductive elec...

Embodiment 2

[0041] Fabrication of hydrogel flexible strain sensors:

[0042] (1) Choline chloride and glucose were mixed in a molar ratio of 1:2, placed in a flask, and magnetically stirred in an oil bath at 100° C. for 2 hours to form a clear deep eutectic solvent for later use.

[0043] (2) Add 20 mL DMSO to the above 10 mL deep eutectic solvent and continue stirring for 30 min. Then 1 g of polyvinyl alcohol was added and stirred, 1 mL of cellulose nanocrystal solution and 1 mL of graphitic carbon nitride solution were added, and the stirring was continued for 5 h.

[0044] (3) Pour the material obtained in step (2) into a petri dish, place it in the refrigerator, and freeze it at -20°C for 20 hours to freeze and polymerize to form a polyvinyl alcohol network. Take it out and place it at room temperature for 2 hours before placing it in the refrigerator. Store at 20°C for 6 hours to obtain a hydrogel.

[0045] (3) Clean and dry the above hydrogel, install conductive electrodes, and pa...

Embodiment 3

[0047] Fabrication of hydrogel flexible strain sensors:

[0048] (1) Choline chloride and glycerol were mixed in a molar ratio of 1:3 and placed in a flask, and magnetically stirred in an oil bath at 90° C. for 2 hours to form a clear deep eutectic solvent for later use.

[0049] (2) Add 20 mL DMSO to the above 10 mL deep eutectic solvent and continue stirring for 30 min. Then, 2.0 g of polyvinyl alcohol was added and stirred, and 1 mL of cellulose nanocrystal solution and 1 mL of graphitic carbon nitride solution were added, and the stirring was continued for 5 h.

[0050] (3) Pour the material obtained in step (2) into a petri dish, place it in the refrigerator, and freeze it at -20°C for 20 hours to freeze and polymerize to form a polyvinyl alcohol network. Take it out and place it at room temperature for 2 hours before placing it in the refrigerator. Store at 20°C for 6 hours to obtain a hydrogel.

[0051](3) Clean and dry the above hydrogel, install conductive electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com