Potential type microelectrode sensor with universality as well as preparation and application of potential type microelectrode sensor

A micro-electrode and sensor technology, which is applied in the field of potentiometric micro-electrode sensors, can solve the problems of high mechanical strength requirements of the electrodes, and achieve the effects of on-site in-situ detection, low detection limit, and small geometric size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

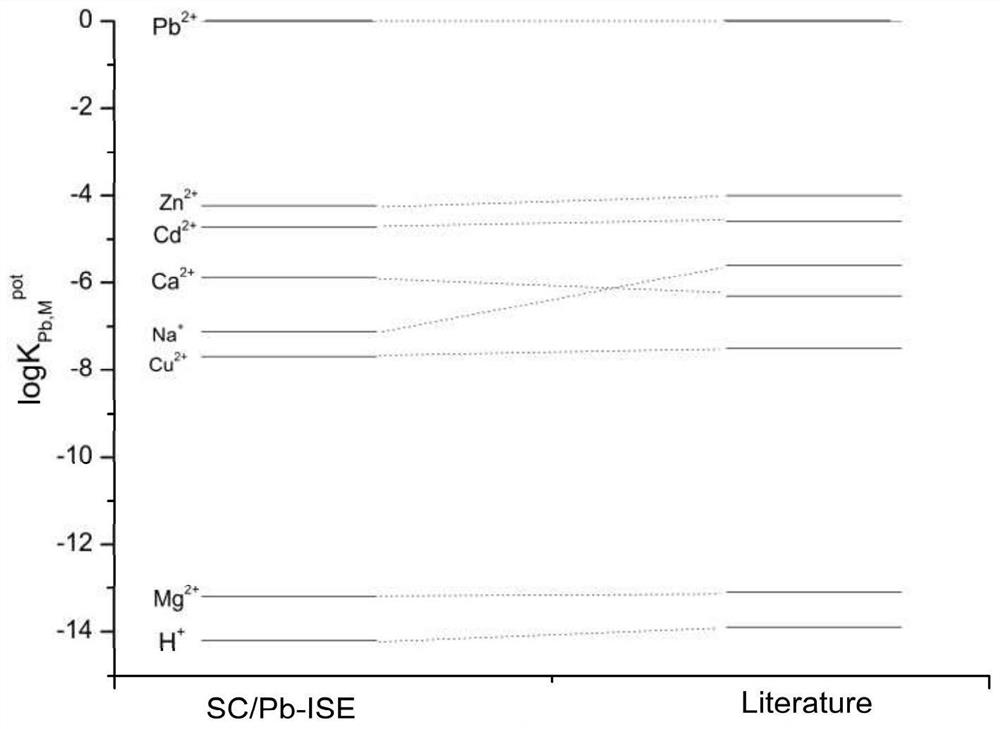

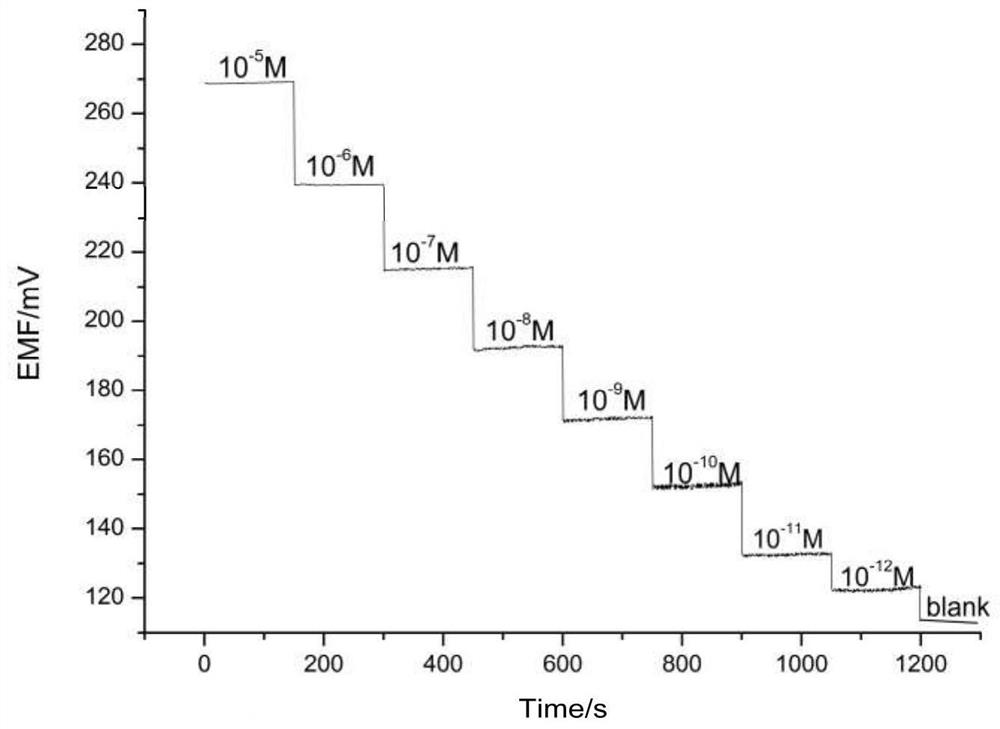

[0067] Take the detection of lead ions, and the filling material is disordered mesoporous carbon as an example;

[0068] Preparation of potentiometric microelectrode sensors:

[0069] 1. First, according to the existing method, one end of a capillary glass tube with an outer diameter of 1 mm and an inner diameter of 0.58 mm is drawn so that the tip is 10 microns. Immerse the capillary glass tube with N,N-dimethyltrimethylsilylamine, silanize it in an oven at 150 degrees Celsius for 3 hours, then take it out and let it cool to room temperature.

[0070] Fill the capillary glass tube obtained above with disordered mesoporous carbon until the tip is full, so that the length of the disordered mesoporous carbon in the tube is 2 cm, then immerse the tip in the ion-selective sensitive membrane solution, and use capillary action to dissolve the membrane solution Inhaled into the capillary tube and mixed with disordered mesoporous carbon ( figure 1 ).

[0071] The ion-selective sens...

Embodiment 2

[0081] Taking the detection of lead ions as an example, the microelectrode filling material is disordered mesoporous carbon, the ion-selective sensitive membrane is the same as that described in Example 1, and the preparation of the potentiometric microelectrode sensor:

[0082] 1. First, according to the existing method, one end of a capillary glass tube with an outer diameter of 1 mm and an inner diameter of 0.58 mm is drawn so that the tip diameter is 10 microns. Immerse the capillary glass tube with N,N-dimethyltrimethylsilylamine, silanize it in an oven at 150 degrees Celsius for 3 hours, then take it out and let it cool to room temperature.

[0083] Fill the capillary glass tube obtained above with disordered mesoporous carbon until the tip is filled, so that the length of the disordered mesoporous carbon in the tube is 2 cm, then immerse the tip in the ion-selective sensitive membrane solution, and use the capillary action of the capillary to dissipate the The membrane ...

Embodiment 3

[0091] Taking the detection of lead ions, the filling material is disordered mesoporous carbon, the ion-selective sensitive membrane is the same as that described in Example 1, and the detection environmental sample is actual seawater as an example. The specific detection steps are as follows:

[0092] 1. First, according to the existing method, one end of a capillary glass tube with an outer diameter of 1 mm and an inner diameter of 0.58 mm is drawn so that the tip is 10 microns. Immerse the capillary glass tube with N,N-dimethyltrimethylsilylamine, silanize it in an oven at 150 degrees Celsius for 3 hours, then take it out and let it cool.

[0093] Fill the capillary glass tube obtained above with disordered mesoporous carbon until the tip is filled, so that the length of the disordered mesoporous carbon in the tube is 2 cm, then immerse the tip in the ion-selective sensitive membrane solution, and use the capillary action of the capillary to dissipate the The membrane solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com