Method for analyzing characteristic aroma components of heat-not-burn cigarette

A heat-not-burn, characteristic aroma technology, applied in the field of tobacco, can solve problems such as low recovery rate, difficult detection, incomplete extraction, etc., and achieve the effects of saving detection cost, improving fault tolerance rate, and enriching diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

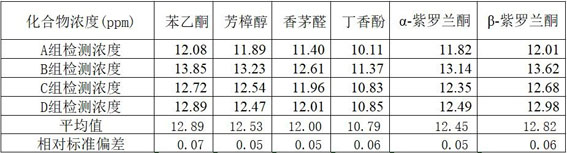

Embodiment 1

[0033] Pretreatment of shredded tobacco of heat-not-burn cigarettes:

[0034] like Figure 4As shown, 1 g of heat-not-burn cigarette shredded tobacco was dried and crushed to 74 μm, and 5 g of 200-mesh SiC was added as a microwave absorbing medium. After mixing and grinding, it was screened through a 200-mesh sieve, mixed evenly with a small three-dimensional mixer, and distributed. Be the first pretreatment sample, the second pretreatment sample, and the third pretreatment sample, wherein, the ratio of parts by weight is not limited, and the total mass of the first pretreatment sample, the second pretreatment sample, and the third pretreatment sample is equal to The quality of the pre-treatment sample; 0.0001g of solid naphthalene was weighed as the first internal standard, and the first pre-treatment sample was mixed with the first internal standard after being ground and screened through a 200-mesh sieve. The mixer is mixed evenly to obtain the first sample to be tested; ...

Embodiment 2

[0047] Pretreatment of shredded tobacco of heat-not-burn cigarettes:

[0048] Such as Figure 4 As shown, 1 g of heat-not-burn cigarette shredded tobacco was dried and crushed to 65 μm, and 2 g of 200-mesh SiC was added as a microwave absorbing medium. After mixing and grinding, it was screened through a 200-mesh sieve, mixed evenly with a small three-dimensional mixer, and distributed. Be the first pretreatment sample, the second pretreatment sample, and the third pretreatment sample, wherein, the ratio of parts by weight is not limited, and the total mass of the first pretreatment sample, the second pretreatment sample, and the third pretreatment sample is equal to The pretreatment sample quality;

[0049] Weigh 0.0002g of solid naphthalene as the first internal standard, mix the first pretreatment sample with the first internal standard, grind and pass through a 200-mesh sieve, and mix evenly with a small three-dimensional mixer to obtain the first internal standard. a sa...

Embodiment 3

[0062] Pretreatment of shredded tobacco of heat-not-burn cigarettes:

[0063] like Figure 4 As shown, 1 g of heat-not-burn cigarette shredded tobacco was dried and crushed to 50 μm, and 3 g of 200-mesh SiC was added as a microwave absorbing medium. After mixing and grinding, it was screened through a 200-mesh sieve, mixed evenly with a small three-dimensional mixer, and distributed. Be the first pretreatment sample, the second pretreatment sample, and the third pretreatment sample, wherein, the ratio of parts by weight is not limited, and the total mass of the first pretreatment sample, the second pretreatment sample, and the third pretreatment sample is equal to The quality of the pre-treatment sample; 0.0001g of solid naphthalene was weighed as the first internal standard, and the first pre-treatment sample was mixed with the first internal standard after being ground and screened through a 200-mesh sieve. The mixer is mixed evenly to obtain the first sample to be tested; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com