A cosmetic preservative removal device

A technology of preservatives and cosmetics, applied in other chemical processes, chemical instruments and methods, solid adsorbent liquid separation, etc., to achieve the effect of reducing the risk of adverse reactions, reducing the content of preservatives, and enhancing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

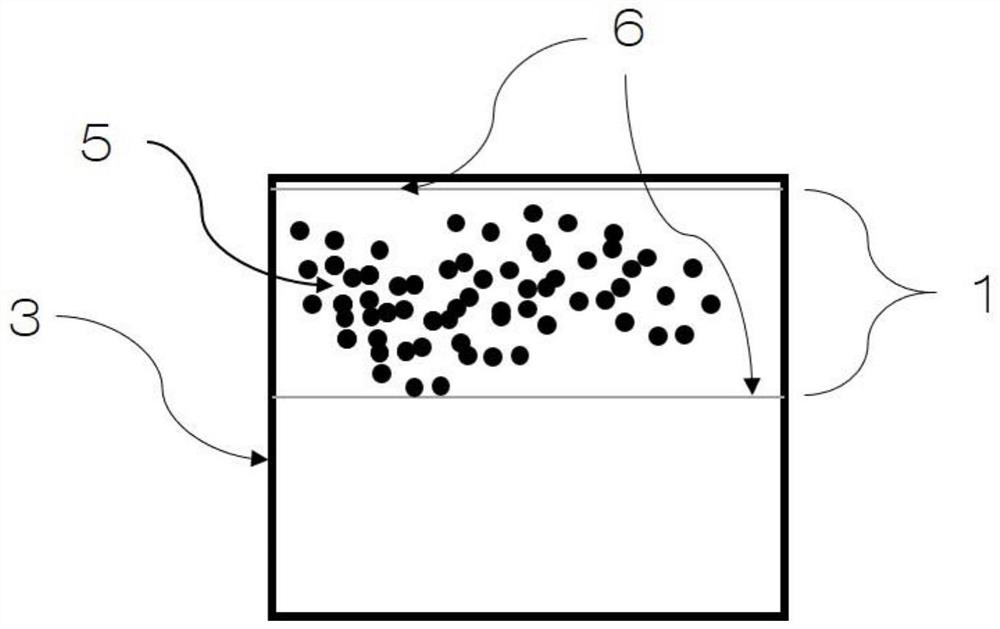

[0035] Preparation of thermally polymerized hydroxyethyl methacrylate / 4-vinylpyridine (HEMA / VP) specific adsorbent (spherical particles):

[0036] (1) After mixing 4 g of hydroxyethyl methacrylate and 2 g of 4-vinylpyridine, 0.1 g of a crosslinking agent polyethylene glycol dimethacrylate was added while stirring to obtain a mixed solution.

[0037] (2) Pour nitrogen into the mixed solution to remove the dissolved oxygen therein, then add 0.1 g initiator azobisisobutyronitrile, drop the solution into 65°C dimethyl silicone oil under the condition of isolating oxygen, and heat The polymerization reaction was carried out for 24 h to obtain solidified pellets.

[0038] (3) Collecting pellets, alternately washing with distilled water and ethanol, and drying to obtain a HEMA / VP specific adsorbent (spherical particles).

Embodiment 2

[0040] Preparation of photopolymerized hydroxyethyl methacrylate / 4-vinylpyridine (HEMA / VP) specific adsorbent (spherical particles):

[0041] (1) After mixing 4 g of hydroxyethyl methacrylate and 2 g of 4-vinylpyridine, 0.1 g of a crosslinking agent polyethylene glycol dimethacrylate was added while stirring to obtain a mixed solution.

[0042] (2) nitrogen was introduced into the mixed solution to remove the dissolved oxygen therein, 0.08g of initiator 2-p-hydroxy-2-methyl-1-phenyl-1-acetone was added, and then the solution was separated from oxygen It was added dropwise to dimethyl silicone oil, and at room temperature, 365nm ultraviolet rays were irradiated for 15 minutes to obtain cured pellets.

[0043] (3) Collecting pellets, alternately washing with distilled water and ethanol, and drying to obtain a HEMA / VP specific adsorbent (spherical particles).

Embodiment 3

[0045] The test of the content change of each component after the homemade cosmetic solution flows through the HEMA / VP specific adsorbent:

[0046] In order to illustrate whether the specific adsorbent of the present invention can cause adsorption loss of typical small-molecule active ingredients and macromolecular active ingredients in cosmetics while removing paraben preservatives. Taking a self-made cosmetic solution as an example, the components of the self-made cosmetic solution are: 1% niacinamide, 0.2% hyaluronic acid, 0.2% methylparaben, 0.1% ethylparaben.

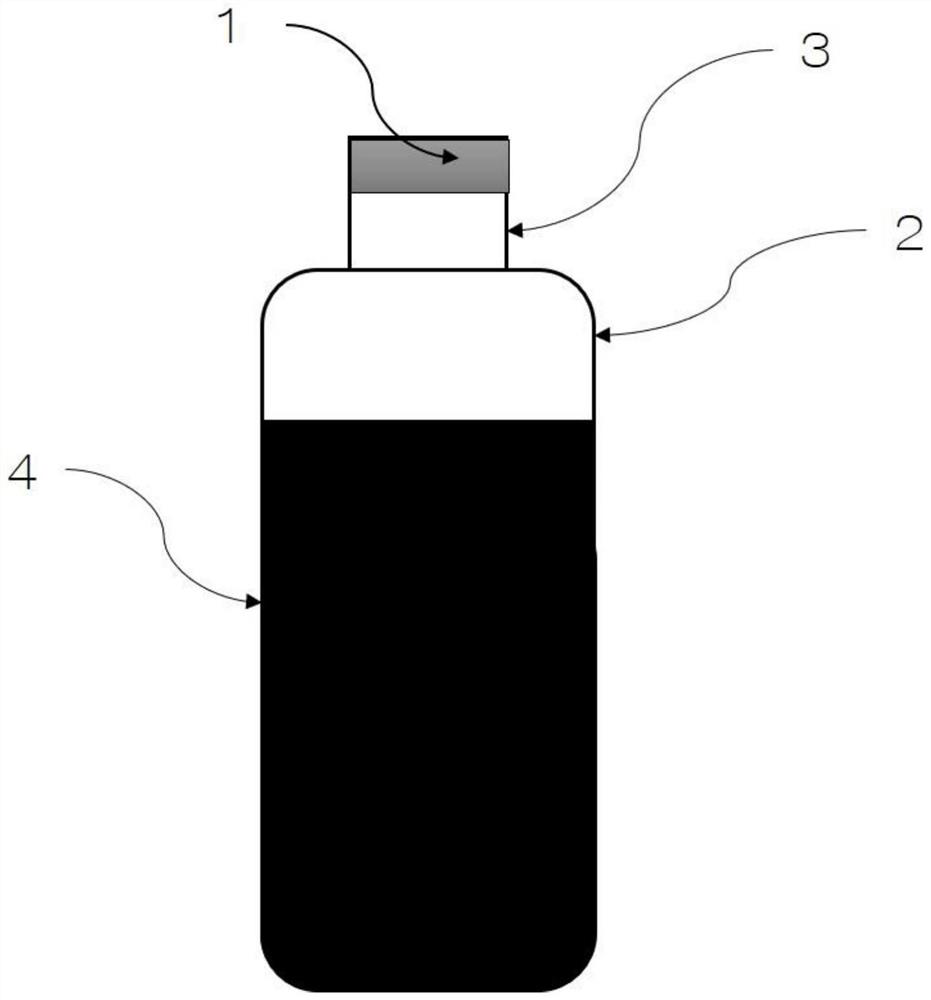

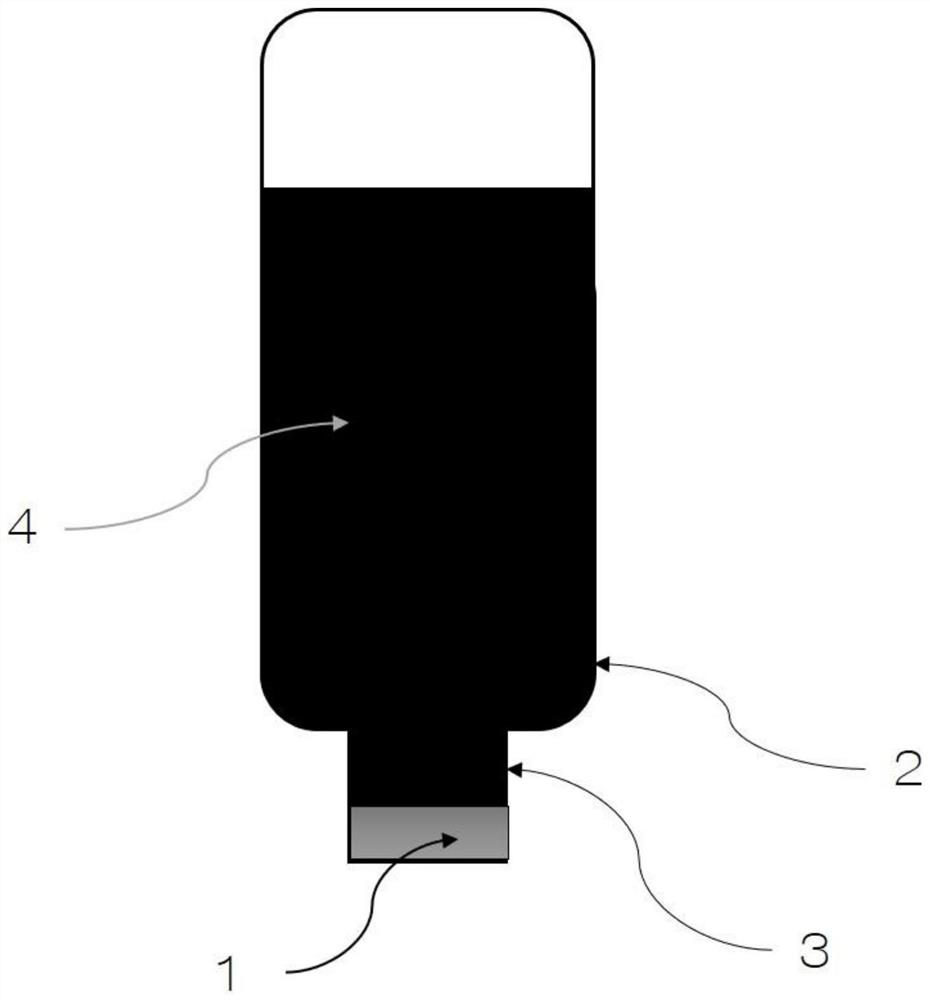

[0047] 50 mL of the self-made cosmetic solution was put into a PP bottle; the HEMA / VP specific adsorbent provided in Example 1 was fixed with a PP mesh that fits with the mouth of the PP bottle, and then it was packaged in the mouth of the PP bottle. Invert the PP bottle and pour out the self-made cosmetic solution, simulate the use process, repeat the pouring 5 times, pour about 10 mL at a time, and then measure t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com