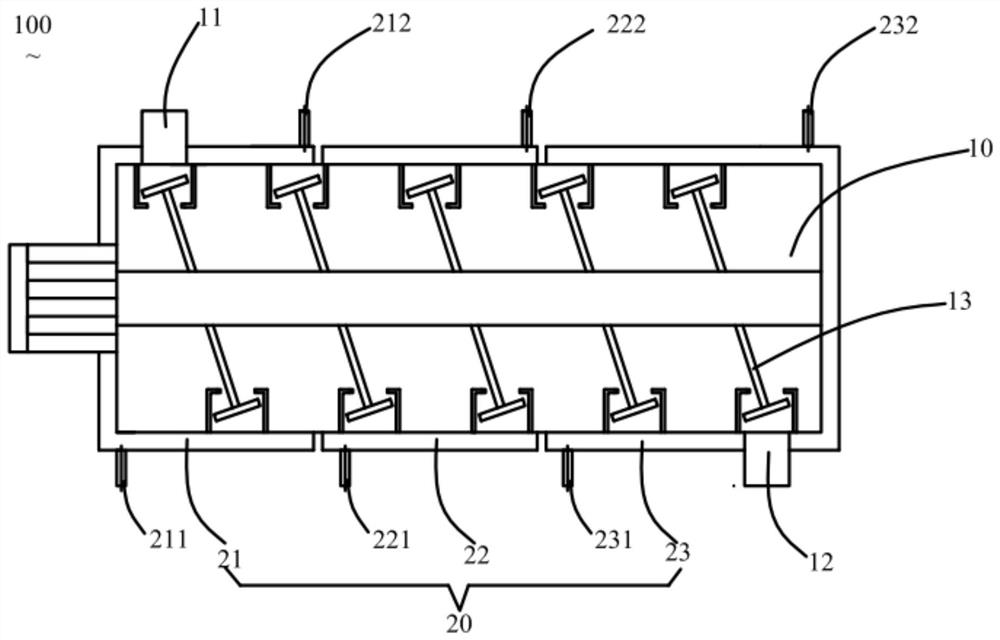

Method for continuously synthesizing epichlorohydrin rubber by using kneading reactor

A chlorohydrin rubber and reactor technology, applied in the field of rubber manufacturing, can solve the problems of wide molecular weight distribution of rubber, difficult to control polymerization temperature, low stirring and mixing efficiency, etc., to achieve good product quality, reduce cleaning and wall-hanging glue, and raw material utilization. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

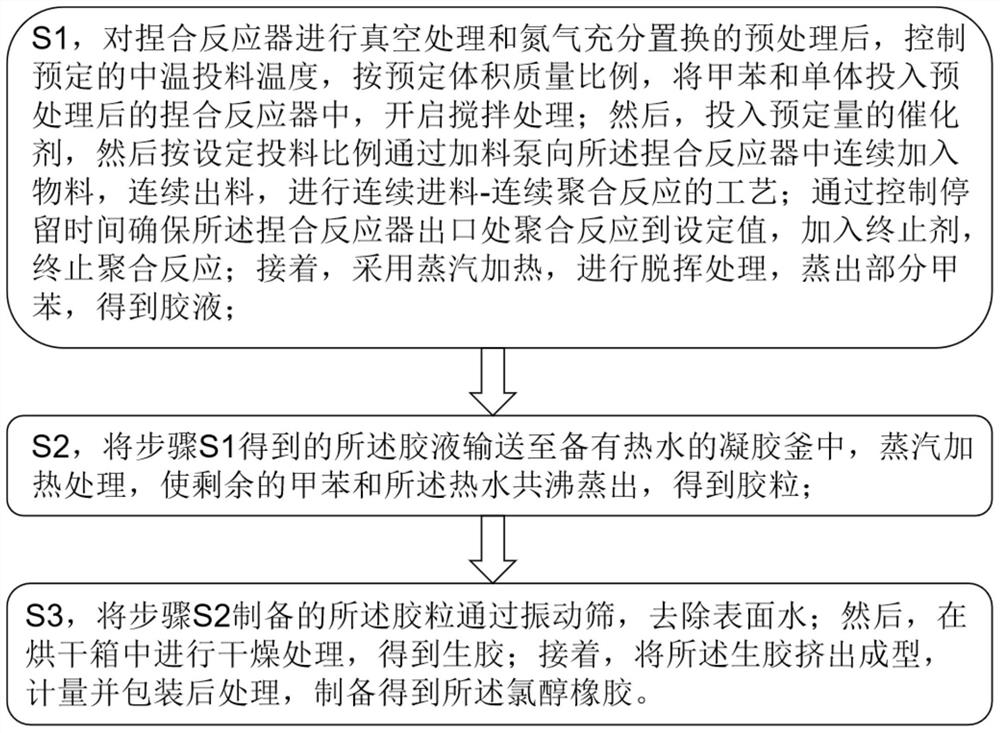

[0060] Embodiment 1 of the present invention provides a method for continuously synthesizing epichlorohydrin rubber using a kneading reactor, comprising the following steps:

[0061] S1, after the pretreatment of the kneading reactor with vacuum treatment and sufficient nitrogen replacement, the refined qualified toluene and epichlorohydrin are put into the pretreated kneading reactor at a ratio of volume to mass ratio of 5L: 1Kg, and the stirring process is started , the control feed temperature is 50 ℃, then, drop into the catalyst of monomer mass 2% (the mass ratio of triisobutylaluminum, phosphoric acid and aniline is 90:180:18), control the polymerization reaction system in the kneading reactor The concentration of the compound is 20%. The material is continuously added to the kneading reactor through the feeding pump, and the material is continuously discharged to carry out the process of continuous feeding-continuous polymerization reaction (the continuous polymerization...

Embodiment 2

[0067] Embodiment 2 of the present invention provides a method for continuously synthesizing epichlorohydrin rubber using a kneading reactor, comprising the following steps:

[0068]S1, after the pretreatment of the kneading reactor with vacuum treatment and sufficient nitrogen replacement, the refined qualified toluene and mixed monomers (epichlorohydrin and ethylene oxide with a mass ratio of 1:1) were mixed in a volume-to-mass ratio of 5.5L : the ratio of 1Kg is put into the kneading reactor after the pretreatment, and the stirring process is started, and the control feeding temperature is 60°C, and then, the catalyst (the mass ratio of triisobutylaluminum, phosphoric acid and aniline of 2% of monomer mass) is dropped into 100:160:20), the concentration of the polymerization reaction system in the kneading reactor is controlled to be 15%, and the materials are continuously added to the kneading reactor through the feed pump, and the materials are continuously discharged, and...

Embodiment 3

[0073] Embodiment 3 of the present invention provides a method for continuously synthesizing epichlorohydrin rubber using a kneading reactor, comprising the following steps:

[0074] S1, after the pretreatment of vacuum treatment and nitrogen full replacement to the kneading reactor, the refined qualified toluene and mixed monomers (epichlorohydrin and propylene oxide with a mass ratio of 2:1) are 5.3L by volume and mass: The ratio of 1Kg is put into the kneading reactor after the pretreatment, and the stirring process is started, and the feeding temperature is controlled to be 70°C, and then, the catalyst (the mass ratio of triisobutylaluminum, phosphoric acid and aniline is 100% by mass) is dropped into 2% of the monomer mass. : 200: 16), controlling the concentration of the polymerization reaction system in the kneading reactor to be 10%, continuously adding materials to the kneading reactor through the feeding pump, continuously discharging, and carrying out the process of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com