Extraction and separation method of lamb abomasum chymosin

A technology of gastric rennet and separation method, which is applied in the field of extraction and separation of lamb rennet, can solve the problems of thermal stability reduction and activity reduction, and achieve the goal of increasing added value, alleviating supply shortage, and solving environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

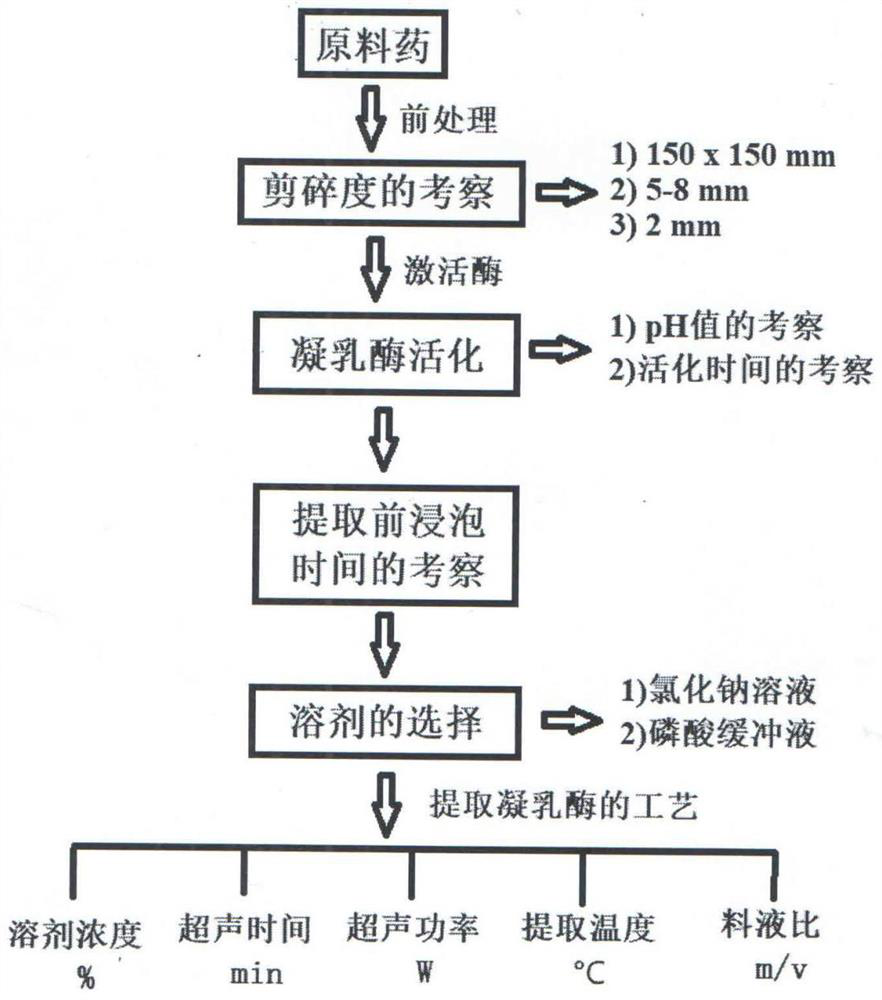

Method used

Image

Examples

Embodiment 1

[0025] a. Choose lamb, take out the abomasum after slaughter, rinse with pre-cooled distilled water running water to remove sundries in the abomasum, and store it in a refrigerator at a temperature of -20°C for later use;

[0026] b. The lamb abomasum cleaned in step a, stripped of fat and connective tissue, cut into squares of 150×150 mm, frozen at -80°C for 12 hours, then freeze-dried, and then pulverized into 5 mm by a pulverizer Sheep abomasum in powder form, stored in a -20°C refrigerator for later use;

[0027] c. Add petroleum ether to the sheep abomasum powder in step b at a temperature of 4°C, and mechanically stir to degrease, degrease twice, add 20 times the volume of distilled water, and soak at a temperature of 18°C for 10 minutes;

[0028] d. Adjust the soaking liquid obtained in step c to a final concentration of 1% sodium chloride solution with sodium chloride, adjust the pH value to 5.6 with 1moL / L hydrochloric acid solution, and use ultrasonic-assisted stirri...

Embodiment 2

[0032] a. Choose lamb, take out the abomasum after slaughter, rinse with pre-cooled distilled water running water to remove sundries in the abomasum, and store it in a refrigerator at a temperature of -20°C for later use;

[0033] b. The lamb abomasum cleaned in step a, stripped of fat and connective tissue, cut into squares of 150×150mm, frozen at -80°C for 12 hours, then freeze-dried, and crushed into 7mm pieces with a pulverizer Sheep abomasum in powder form, stored in a -20°C refrigerator for later use;

[0034] c. Add petroleum ether to the sheep abomasum powder in step b at a temperature of 4°C, and mechanically stir to degrease, degrease twice, add 20 times the volume of distilled water, and soak at a temperature of 18°C for 10 minutes;

[0035] d. Adjust the soaking liquid obtained in step c to a final concentration of 1% sodium chloride solution with sodium chloride, adjust the pH value to 5.6 with 1moL / L hydrochloric acid solution, and use ultrasonic-assisted stirr...

Embodiment 3

[0039] a. Choose lamb, take out the abomasum after slaughter, rinse with pre-cooled distilled water running water to remove sundries in the abomasum, and store it in a refrigerator at a temperature of -20°C for later use;

[0040] b. The lamb abomasum cleaned in step a, stripped of fat and connective tissue, cut into squares of 150×150mm, frozen at -80°C for 12 hours, then freeze-dried, and then pulverized into 8mm by a pulverizer Sheep abomasum in powder form, stored in a -20°C refrigerator for later use;

[0041] c. Add petroleum ether to the sheep abomasum powder in step b at a temperature of 4°C, and mechanically stir to degrease, degrease twice, add 20 times the volume of distilled water, and soak at a temperature of 18°C for 60 minutes;

[0042] d. Adjust the soaking liquid obtained in step c to a final concentration of 1% sodium chloride solution with sodium chloride, adjust the pH value to 5.6 with 1moL / L hydrochloric acid solution, and use ultrasonic-assisted stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com