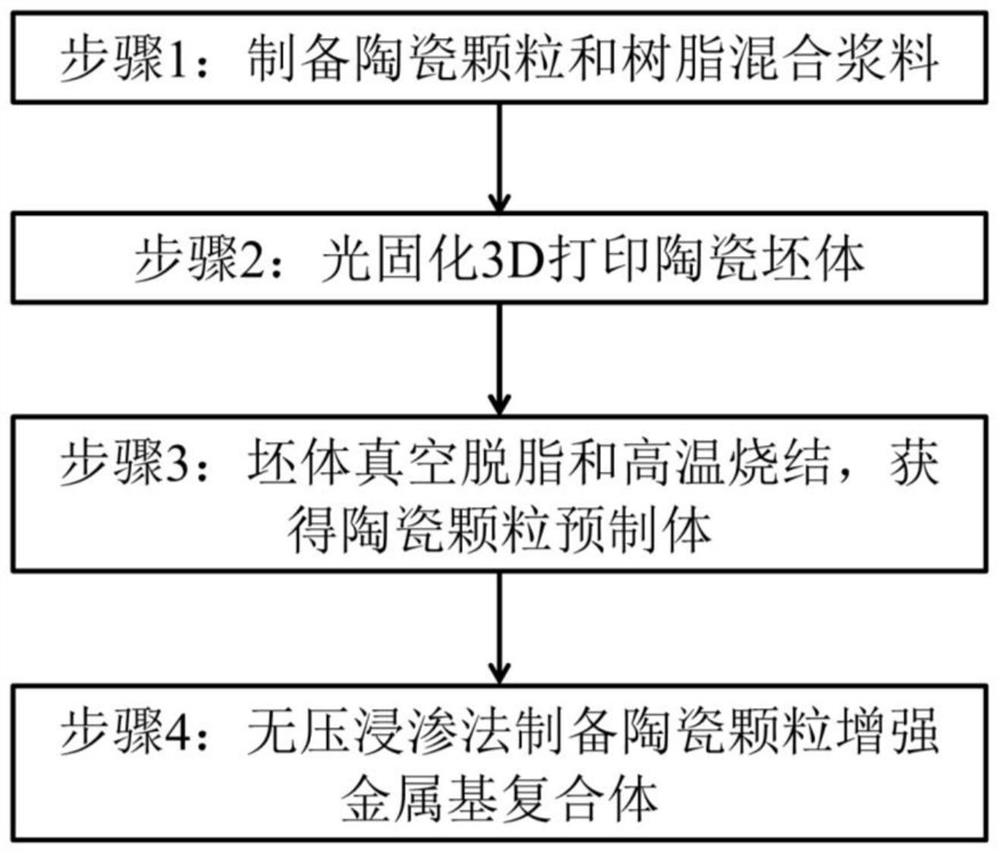

Preparation method of ceramic particle reinforced metal-based composite material

A technology of ceramic particles and composite materials, which is applied in the field of preparation of ceramic particle-reinforced metal-matrix composite materials, can solve problems such as easy segregation, uneven composition, and affecting performance, so as to ensure bonding strength and compactness, excellent performance, and improve Yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

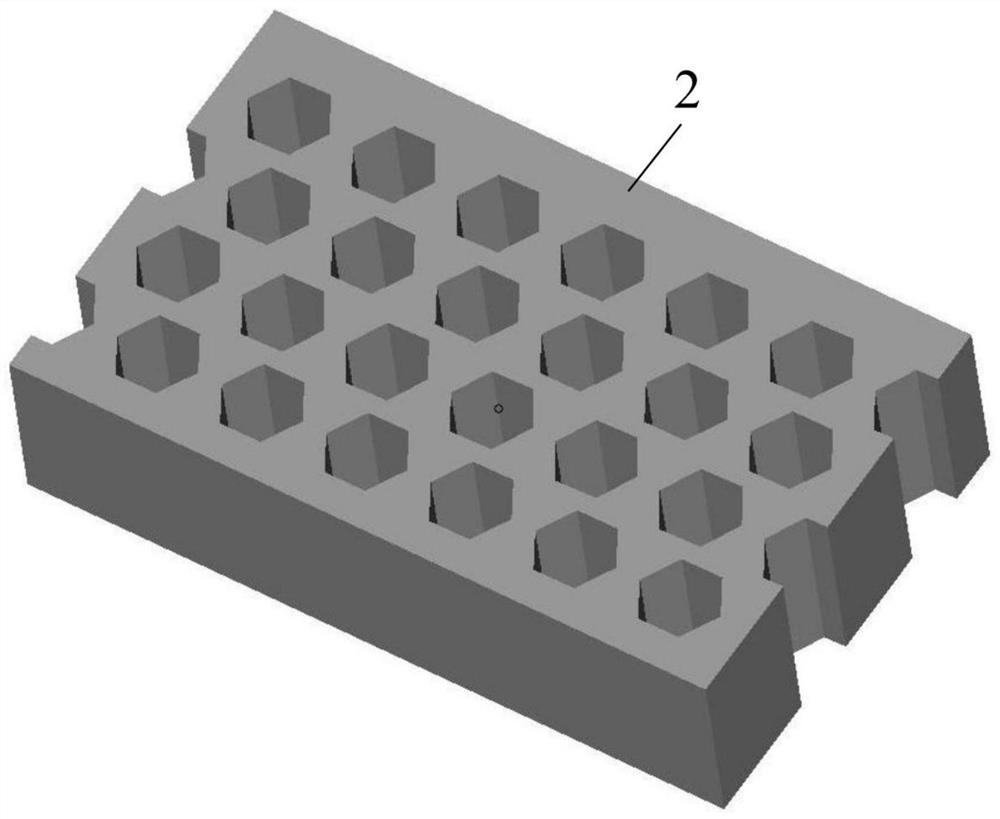

[0028] Adopt the present invention to manufacture a kind of ZrO with honeycomb structure 2 2 The preparation method of the ceramic particle reinforced steel matrix composite material, the specific steps are as follows:

[0029] (1) Preparation of ZrO 2 Ceramic particles and resin mixed slurry, to ZrO 2 Add absolute ethanol, 2-hydroxy-2-methyl-1-phenylacetone, trimethylolpropane triacrylate, BYK-9076 to the ceramic particles, and fully ball mill and stir. The ball mill medium is spherical zirconia with a diameter of 8mm, and the ball milling time is 6h to obtain a uniformly dispersed mixed slurry;

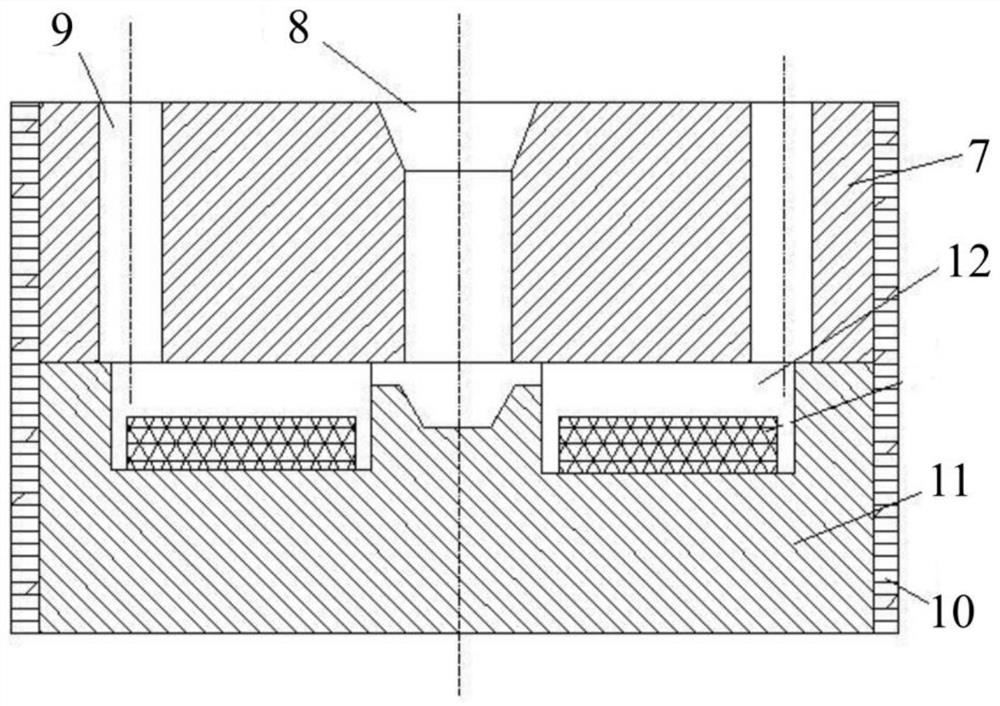

[0030] (2) if Figure 8 As shown in the photo-curing 3D printing ceramic body, the solidworks three-dimensional modeling software is used to build a model of the ceramic particle body with a honeycomb structure, and the layering software is used to perform layering processing along the Z axis to discretize the three-dimensional information and obtain each layer The two-dimension...

Embodiment 2

[0035] Utilizing the present invention to manufacture a method for preparing a WC ceramic particle reinforced copper-based composite material having a body diagonal structure 3 with rounded corners, the specific steps are as follows:

[0036](1) Prepare WC ceramic particles and resin mixed slurry, add absolute ethanol, 2-hydroxy-2-methyl-1-phenylacetone, trimethylolpropane triacrylate, BYK-9076 to WC ceramic particles , fully stirred by ball milling, the ball milling medium is spherical zirconia with a diameter of 5 mm, and the ball milling time is 6 hours to obtain a uniformly dispersed mixed slurry;

[0037] (2) Light-curing 3D printing ceramic body, using SolidWorks and Magics three-dimensional modeling software to construct a ceramic particle body with a rounded body diagonal structure 3 (composed of rounded body diagonal units 5) For the model, use layering software to carry out layering processing along the Z axis to discretize the three-dimensional information, obtain t...

Embodiment 3

[0042] Utilizing the present invention to manufacture a method for preparing a TiC ceramic particle-reinforced titanium-based composite material with a body diagonal structure 4 without rounded corners, the specific steps are as follows:

[0043] (1) Prepare TiC ceramic particles and resin mixed slurry, add absolute ethanol, 2-hydroxy-2-methyl-1-phenylacetone, trimethylolpropane triacrylate, BYK-9076 to TiC ceramic particles , fully stirred by ball milling, the ball milling medium is spherical zirconia with a diameter of 3 mm, and the ball milling time is 6 hours to obtain a uniformly dispersed mixed slurry;

[0044] (2) Light-curing 3D printing ceramic body, using SolidWorks, Magics three-dimensional modeling software to construct a ceramic particle body with a body diagonal structure 4 (composed of body diagonal units 6 without round corners) For the model, use layering software to carry out layering processing along the Z axis to discretize the three-dimensional information...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com