Ligament regeneration stent with gradient induction activity and preparation method thereof

A technology for inducing activity and ligaments, applied to stents, devices for coating liquid on the surface, textiles, etc., to achieve the effects of improving the fatigue performance of the stent, improving the load capacity, and avoiding fatigue failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

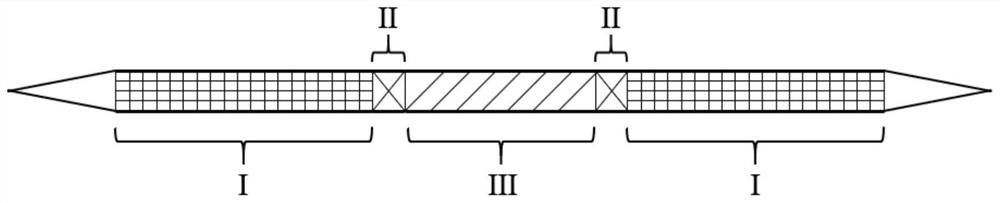

[0048] A preparation method of a ligament regeneration scaffold with gradient-induced activity:

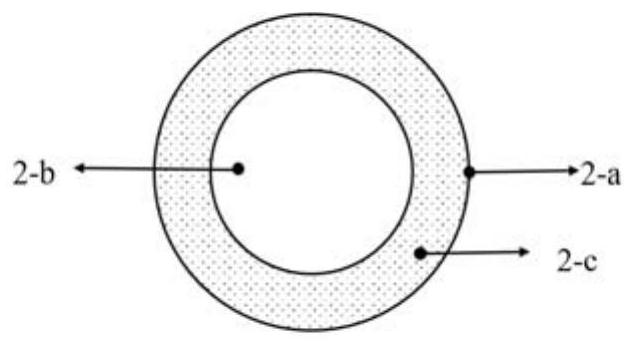

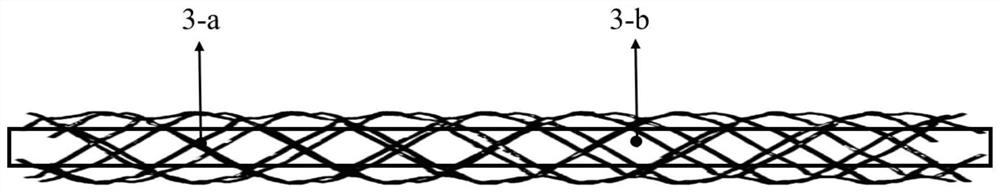

[0049] Step 1: Prepare multi-component degradable composite yarn: adopt two-way weaving molding process, use PCL monofilament 3-a for the shell yarn, and PGCL monofilament 3-b for the core yarn, and obtain the front and back of PCL monofilament wrapped around PGCL monofilament Symmetrically interlaced, PCL monofilament two-up and two-down interlaced biodegradable composite yarn for use, such as image 3 shown;

[0050] Step 2: Prepare the stent preform: adopt the machine-woven integrated molding technology, use PGCL yarn for the warp, and use the degradable composite yarn obtained in step 1 for the weft, and carry out weaving on the machine to obtain the stent preform;

[0051] Step 3: Wash the stent prefabricated body prepared in Step 2 with 75% ethanol, then dry it at 37°C, and set aside;

[0052] Step 4: Gradient impregnation-hot melt treatment: add 50 mg of nano-hydroxyapati...

Embodiment 2

[0056] Step 1: Prepare multi-component degradable composite yarn: adopt three-way weaving molding process, select PLLA monofilament 4-a as the braiding yarn, and introduce PPDO monofilament 4-b as the shaft yarn at the same time to obtain PLLA monofilament two The degradable composite yarn with double interweaving and PPDO interweaving along the axial direction of the degradable composite yarn, such as Figure 4 shown;

[0057] Step 2: Preparing the scaffold preform: using the machine-woven integrated molding technology, the warp yarn is made of PLLA monofilament, the weft yarn is made of the degradable composite yarn obtained in step 1 and the PLLA monofilament is arranged according to the ratio of 1:1, and the weaving is carried out on the machine to obtain Stent preform;

[0058] Step 3: Wash the stent prefabricated body prepared in Step 2 with 75% ethanol, then dry it at 37°C, and set aside;

[0059] Step 4: Gradient impregnation-hot-melt treatment: Add 1 g of nano-β-TCP...

Embodiment 3

[0063] Step 1: Prepare multi-component degradable composite yarn: adopt twisting molding process, use PCL monofilament 5-a for shell yarn, and PLLA monofilament 5-b for core yarn, and obtain PCL monofilament wrapped around PLLA monofilament in the shape of "S "Twist-coated biodegradable composite yarns, such as Figure 4 shown;

[0064] Step 2: Prepare the scaffold preform: adopt the weaving integrated molding technology, the loading ratio of PLLA monofilament and degradable composite yarn is 3:1, and carry out weaving on the machine to obtain the scaffold preform;

[0065] Step 3: Wash the stent prefabricated body prepared in Step 2 with 75% ethanol, then dry it at 37°C, and set aside;

[0066] Step 4: Gradient impregnation-hot-melt treatment: Add 5 g of mesoporous bioglass (MBG) particles into 100 mL of deionized water and disperse ultrasonically for 60 minutes to obtain MBG solution; place the scaffold preformed bone tunnel segment obtained in step 3 in Immerse in MBG sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com