An anti-infection electrospinning degradable hernia prosthesis and preparation method thereof

An electrospinning and anti-infection technology, which is applied in the direction of electrospinning, filament/thread forming, textiles and papermaking, etc., can solve the problems of easy shedding of antibacterial substances, poor anti-infection effect, unfavorable growth of new capillaries and wounds Repair and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of an anti-infection electrospinning degradable hernia patch, comprising the following steps:

[0031] mixing polyurethane solution, gallic acid and polyvinyl alcohol to obtain a spinning solution;

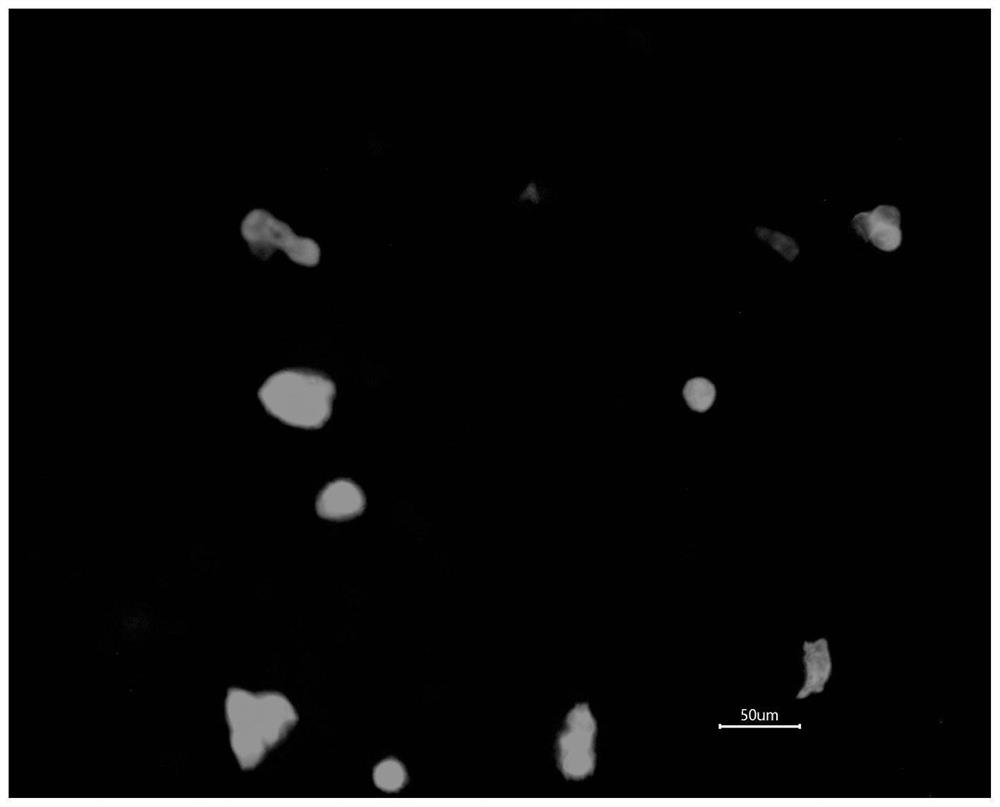

[0032] Electrospinning the spinning solution to obtain a spun film;

[0033] The spinning film is soaked in water, and the polyvinyl alcohol is dissolved to obtain an anti-infection electrostatic spinning degradable hernia patch.

[0034] The invention mixes polyurethane solution, gallic acid and polyvinyl alcohol to obtain spinning solution. In the present invention, the preparation method of the polyurethane solution preferably includes the following steps: mixing diisocyanate, polycaprolactone and an organic solvent to carry out polycondensation reaction to obtain a prepolymer; Mixed with organic tin catalyst, a chain extension reaction occurs to obtain a polyurethane solution.

[0035] In the present invention, it is prefer...

Embodiment 1

[0052] 10g of polycaprolactone with a number average molecular weight of 30000, 0.758g of diphenylmethane diisocyanate and 21.952g of dimethylformamide were put into a machine equipped with mechanical stirring, reflux condenser and N 2 In the three-necked flask with inlet and outlet, magnetically stir until dissolved, and in N 2 Polycondensation reaction at 80°C for 3 hours under protection to obtain a prepolymer;

[0053] Add 0.218g of 1,4-butanediol to the above prepolymer, drop 2 to 3 drops of dibutyltin dilaurate, and conduct a chain extension reaction at 110°C for 9 hours to obtain a transparent polyurethane solution with a solid content of 25%. ;

[0054] Mix 3 g of the polyurethane solution, 0.009 g of gallic acid and 0.5 g of a 10 wt % polyvinyl alcohol aqueous solution, homogenize under ultrasonic conditions (ultrasonic power is 60 W, time is 2 h), to obtain a spinning solution;

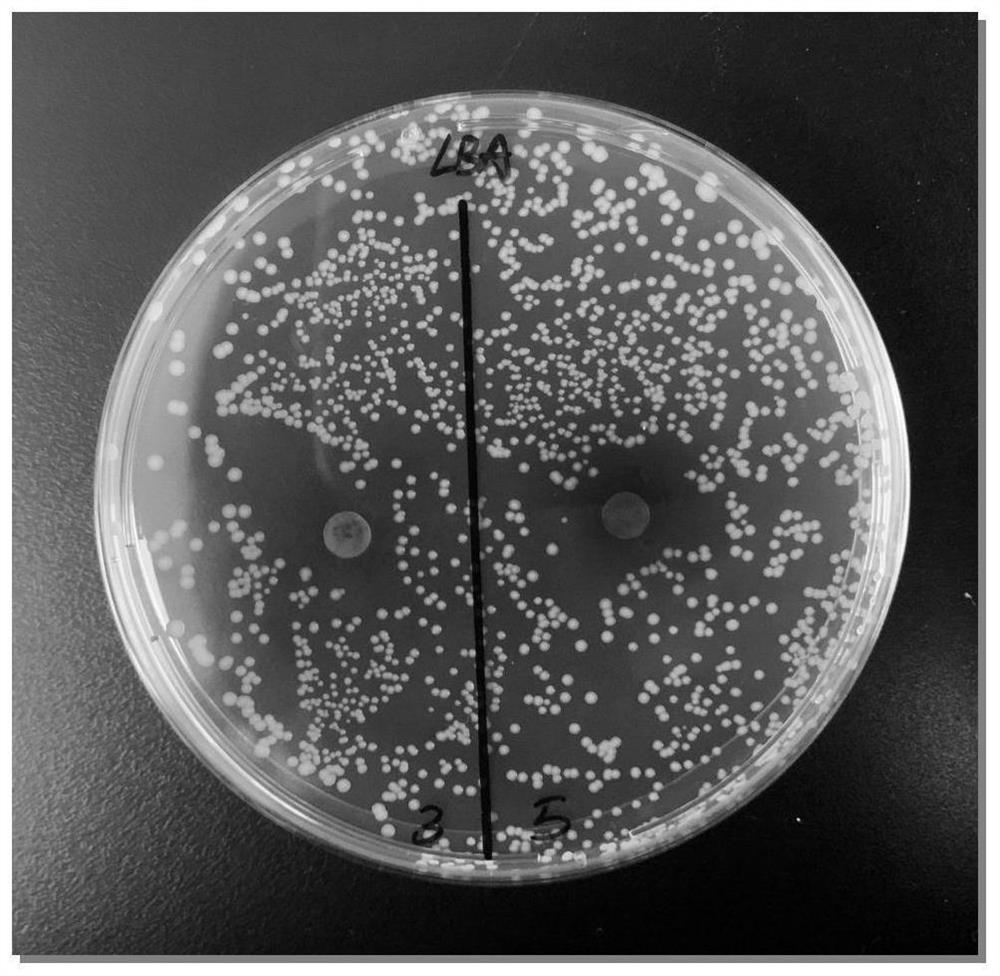

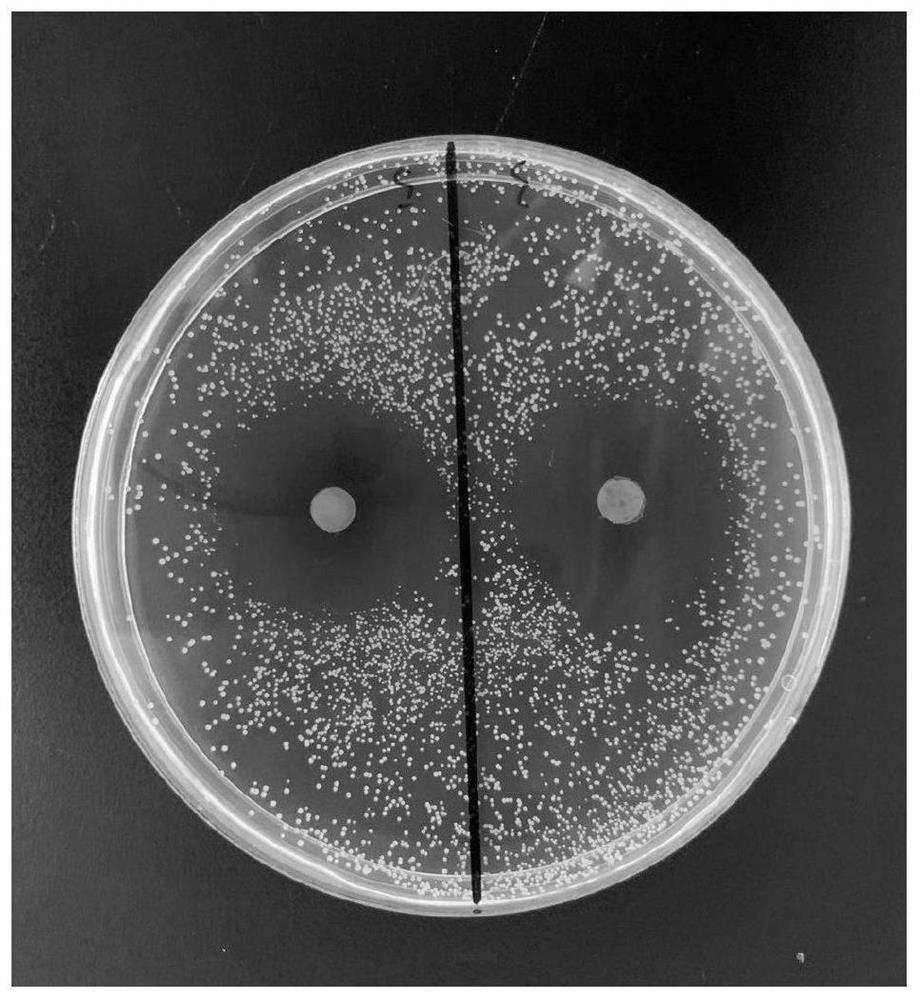

[0055] Set up the spray table, put the spinning solution into a 5mL syringe in the spr...

Embodiment 2

[0059] Put 10g of polycaprolactone with a number average molecular weight of 20000, 0.758g of dicyclohexylmethane diisocyanate and 21.952g of tetrahydrofuran into a device equipped with mechanical stirring, reflux condenser and N 2 In the three-necked flask with inlet and outlet, magnetically stir until dissolved, and in N 2 Polycondensation reaction at 70°C for 4 hours under protection to obtain a prepolymer;

[0060] Add 0.218g of 1,4-butanediol to the above prepolymer, drop 2 to 3 drops of dibutyltin dilaurate, and conduct a chain extension reaction at 90°C for 10 hours to obtain a transparent, high-viscosity, solid content of 25%. Polyurethane solution;

[0061] Mix 3 g of the polyurethane solution, 0.027 g of gallic acid and 0.7 g of a 10 wt % polyvinyl alcohol aqueous solution, homogenize under ultrasonic conditions (ultrasonic power is 80 W, time is 1 h), to obtain a spinning solution;

[0062] Set up the spray table, put the spinning solution into a 5mL syringe in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com