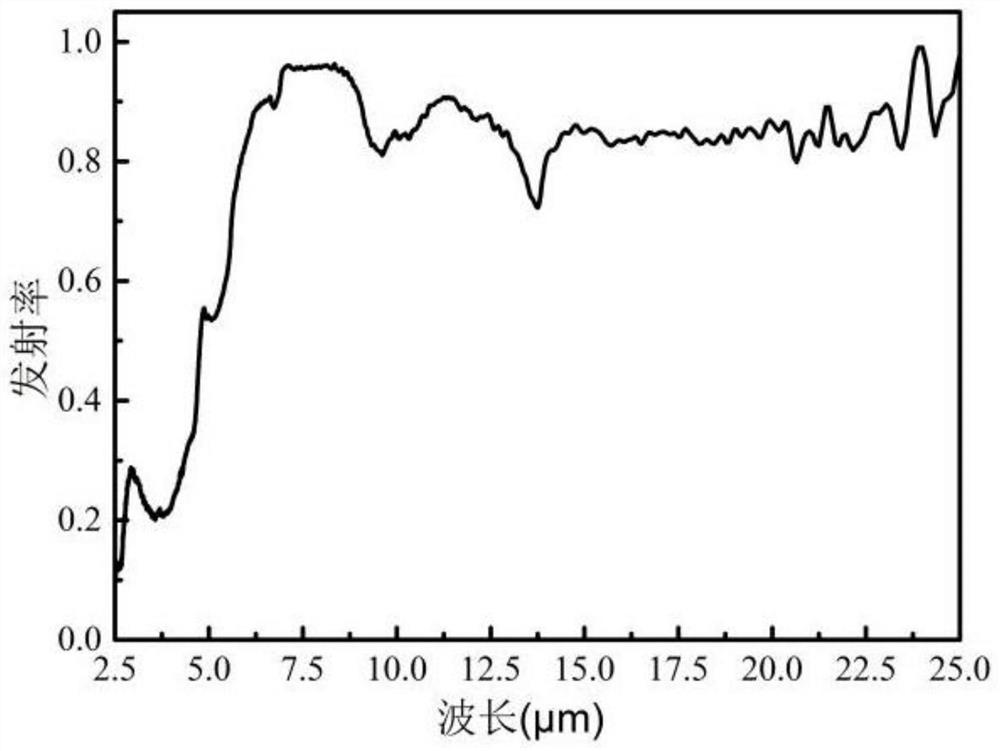

A high temperature resistant spectrally selective infrared stealth coating and its preparation method

A selective, high-temperature-resistant technology, applied in optics, optical filters, optical components, etc., can solve the problems of difficult stealth coatings, etc., to facilitate large-area preparation and application, simple and feasible preparation process, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a high temperature resistant spectrally selective infrared stealth coating, comprising the following steps:

[0035] 1) Raw material preparation:

[0036] Inorganic phase preparation: 90g of zirconia, 5g of cerium oxide, 5g of calcium oxide; the purity of the oxides is ≥99%, and the average particle size is 1.0-3.0μm;

[0037] Preparation of organic phase: Dissolve ethyl cellulose in terpineol at 90°C, and obtain a yellow transparent liquid in a mass ratio of 4:96 between ethyl cellulose and terpineol;

[0038] Preparation of functional aids: dispersant is selected from stearic acid with functional amine; sintering aid is selected from lithium chloride; dispersant and sintering aid are in a mass ratio of 1:1;

[0039] Inorganic phase, organic phase, functional additives, according to the mass ratio of 61:38:1;

[0040] 2) Mix the organic phase obtained in the previous step with the disperser uniformly, then mix it with the inorganic phase, and ...

Embodiment 2

[0044] A preparation method of a high temperature resistant spectrally selective infrared stealth coating, comprising the following steps:

[0045] 1) Raw material preparation:

[0046] Inorganic phase preparation: 70g of cerium oxide, 5g of calcium oxide, 20g of magnesium oxide; the purity of the oxides is ≥99%, and the average particle size is 1.0-3.0μm;

[0047] Organic phase preparation: Dissolve ethyl cellulose in terpineol at 90°C, and obtain a yellow transparent liquid in a mass ratio of 6:94 between ethyl cellulose and terpineol;

[0048] Preparation of functional additives: dispersant is selected from stearic acid with acid ester; sintering aid is selected from lithium oxide; dispersant and sintering aid are in a mass ratio of 1:1;

[0049] Inorganic phase, organic phase, functional additives, according to the mass ratio of 63:36:1;

[0050] 2) Mix the organic phase obtained in the previous step with the disperser uniformly, then mix with the inorganic phase, and un...

Embodiment 3

[0054] A preparation method of a high temperature resistant spectrally selective infrared stealth coating, comprising the following steps:

[0055] 1) Raw material preparation:

[0056] Inorganic phase preparation: 10g calcium oxide, 40g cerium oxide, 30g zirconium oxide, 20g aluminum oxide; the purity of the oxide is ≥99%, and the average particle size is 1.0-3.0μm;

[0057] Preparation of organic phase: Dissolve ethyl cellulose in terpineol at 90°C, and obtain a yellow transparent liquid in a mass ratio of 5:95 between ethyl cellulose and terpineol;

[0058] Preparation of functional aids: dispersant is selected from stearic acid with alcohol group; sintering aid is selected from yttrium oxide; dispersant and sintering aid are in a mass ratio of 1:1;

[0059] Inorganic phase, organic phase, functional additives, according to the mass ratio of 62:37:1;

[0060] 2) Mix the organic phase obtained in the previous step with the disperser uniformly, then mix with the inorganic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com