Method for extracting rubidium chloride from rubidium-containing high-salt brine

A rubidium chloride and brine technology, applied in chemical instruments and methods, rubidium/cesium/francium compounds, inorganic chemistry, etc., can solve the problems of volume increase, increase the cost of recovering other salts in salt brine, etc., and reduce the cost of follow-up treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

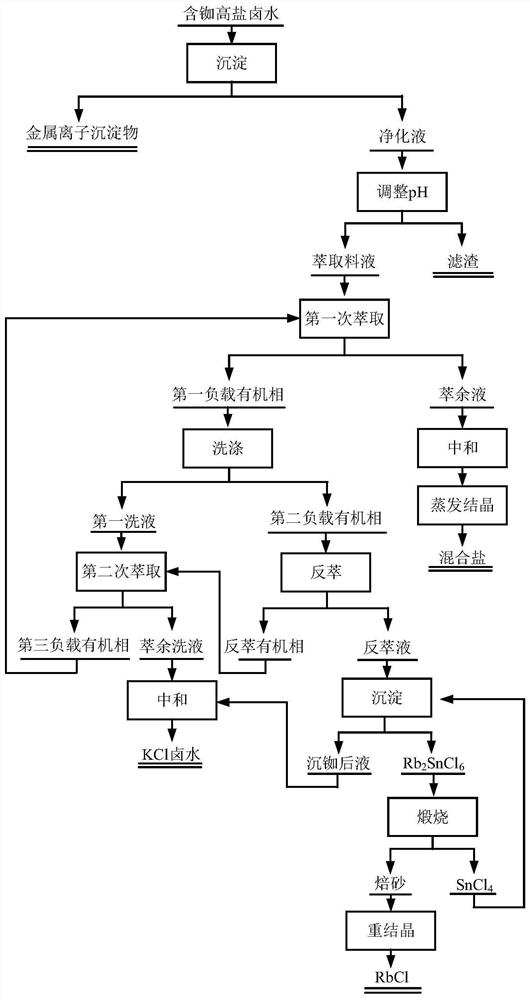

[0046] use figure 1 The process flow shown is to extract rubidium from a certain sintered mineral leach solution (ie high potassium salt brine containing rubidium), and its main metal components are shown in Table 1.

[0047] Table 1 Main metal components of sintered mineral leachate

[0048] Element Rb Cs K Na Cu Zn Content (g / L) 3.74 0.40 142.42 50.13 3.25 1.27

[0049] In the present embodiment, the method for extracting rubidium chloride from rubidium-containing high-salt brine, the steps are as follows:

[0050] S1: Add KOH to the rubidium-containing high-potassium salt brine (ie sintered mineral leachate), adjust the pH value of the rubidium-containing high-potassium salt brine to 10, let it stand for 2 hours, precipitate metal ions, and filter to remove the metal Ion precipitation to obtain a purified solution;

[0051] S2: adding KOH to the purification solution obtained in step S1, adjusting the pH value of the purification solut...

Embodiment 2

[0067] use figure 1 The process flow shown is to extract rubidium in a certain solid waste leach solution (ie high potassium salt brine containing rubidium), and its main metal components are shown in Table 5.

[0068] Table 5 Main metal components of solid waste leachate

[0069] Element Rb Cs K Na Cu Zn Pb Content (g / L) 2.74 0.005 102.21 23.16 1.90 10.02 1.20

[0070] In the present embodiment, the method for extracting rubidium chloride from rubidium-containing high-salt brine, the steps are as follows:

[0071] S1: Add KOH to the rubidium-containing high-potassium salt brine (i.e. solid waste leaching solution), adjust the pH value of the rubidium-containing high-potassium salt brine to 10, let it stand for 2 hours, precipitate metal ion precipitates, and filter to remove the metal Ion precipitation to obtain a purified solution;

[0072] S2: adding KOH to the purification solution obtained in step S1, adjusting the pH value of the...

Embodiment 3

[0088] use figure 1 The process flow shown is to extract rubidium in a simulated rubidium-containing high-potassium salt lake water (ie, rubidium-containing high-potassium salt brine), and its main metal components are shown in Table 9.

[0089] Table 9 The main metal components of simulated rubidium-containing high-potassium salt lake water

[0090] Element Rb Cs K Na Li Mg Content (g / L) 0.21 0.002 27.72 96.95 6.85 28.38

[0091] In the present embodiment, the method for extracting rubidium chloride from rubidium-containing high-salt brine, the steps are as follows:

[0092] S1: Add KOH to the rubidium-containing high-potassium salt brine (that is, the simulated rubidium-containing high-potassium salt lake water), adjust the pH value of the rubidium-containing high-potassium salt brine to 10, let stand for 2 hours, precipitate metal ions, and filter removing the metal ion precipitate to obtain a purified solution;

[0093] S2: adding KOH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com