Anaerobic electrochemical sludge disposal device of electrode coupled flat sheet membrane

A technology for electrode coupling and sludge treatment, which is applied in the fields of membrane separation and anaerobic electrochemistry, can solve the problems of complex manufacturing of folding plate membrane modules, complex structure of rotating electrodes, and complex structure of membrane modules, so as to improve internal digestion efficiency and reduce The deposition of membrane fouling substances and the effect of improving effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

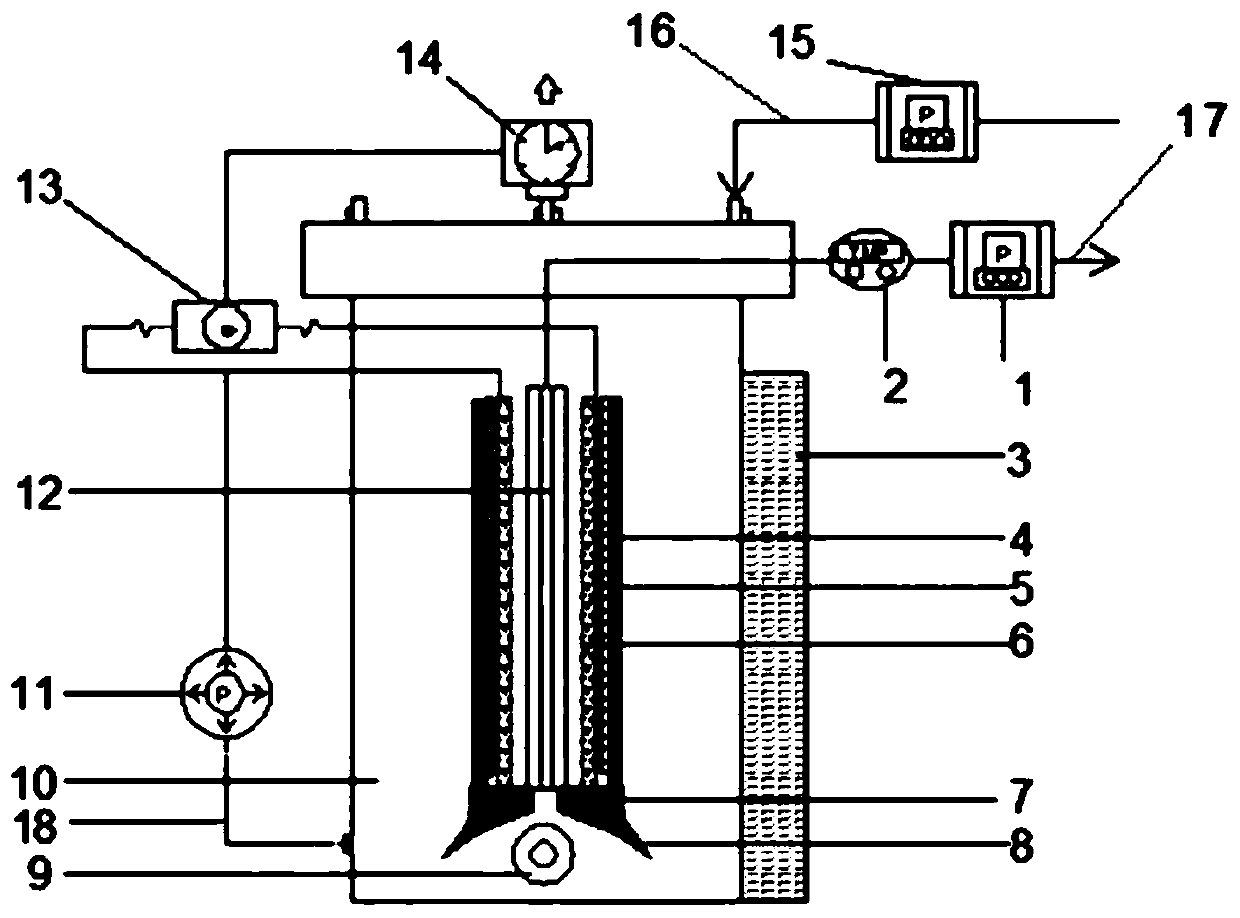

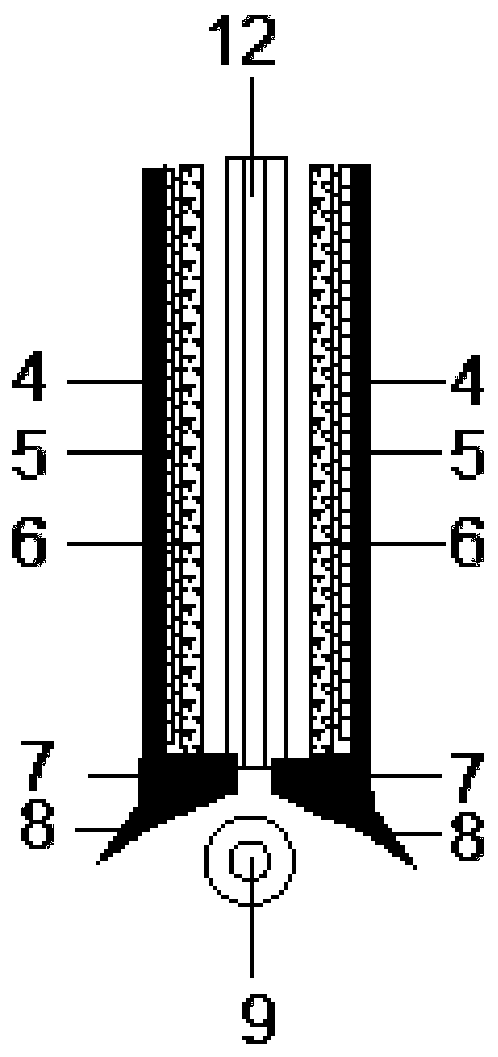

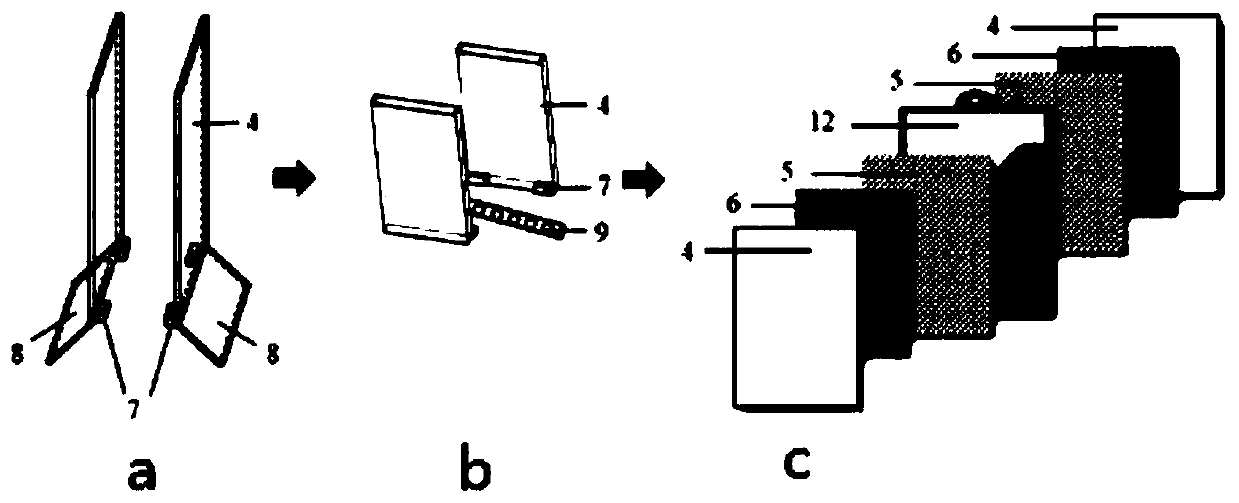

[0034] See attached figure 1 , the sludge and kitchen waste were mixed at a volatile solid ratio of 0.4:0.6 as the sample injection matrix, the total solid content was 6-7 g / L, the volatile solid content was 3-4 g / L, and the total chemical requirement The oxygen content is 0.7~0.9 g / L. The matrix enters the anaerobic membrane bioreactor 10 through the sludge peristaltic pump 15 , and then the purified effluent flows out from the water outlet on the upper part of the flat membrane module 12 under the suction of the effluent peristaltic pump 1 . Control the speed of the circulating air pump 11 to be 5 L / min, and set it to work for two minutes every two hours. Adjust the rate of the effluent peristaltic pump 1, and control the hydraulic retention time to 10 days. Adjust the temperature of the insulation layer 3 so that it is controlled at 35 ± 1°C; the voltage of the potential control device 13 is controlled at 0.4 V; the wet gas flow meter 14 records the daily biogas productio...

Embodiment 2

[0036] Sludge and food waste were mixed at a volatile solid ratio of 0.4:0.6 as the sample injection matrix. The total solid content was 6-7 g / L, the volatile solid content was 3-4 g / L, and the total COD It is 0.7~0.9 g / L. The matrix enters the anaerobic membrane bioreactor 10 through the sludge peristaltic pump 15 , and then the purified effluent flows out from the water outlet on the upper part of the flat membrane module 12 under the suction of the effluent peristaltic pump 1 . Control the speed of the circulating air pump 11 to be 5 L / min, and set it to work for two minutes every two hours. Adjust the rate of the effluent peristaltic pump 1, and control the hydraulic retention time to 10 days. Adjust the temperature of the insulation layer 3 so that it is controlled at 35 ± 1°C; the voltage of the potential control device 13 is controlled at 0.4 V; the wet gas flow meter 14 records the daily biogas production; the pressure gauge 2 records the permeable membrane of the fla...

Embodiment 3

[0038] Sludge and food waste were mixed at a volatile solid ratio of 0.4:0.6 as the sample injection matrix. The total solid content was 6-7 g / L, the volatile solid content was 3-4 g / L, and the total COD It is 0.7~0.9 g / L. The matrix enters the anaerobic membrane bioreactor 10 through the sludge peristaltic pump 15 , and then the purified effluent flows out from the water outlet on the upper part of the flat membrane module 12 under the suction of the effluent peristaltic pump 1 . Control the speed of the circulating air pump 11 to be 5 L / min, and set it to work for two minutes every two hours. Adjust the rate of the effluent peristaltic pump 1, and control the hydraulic retention time to 10 days. Adjust the temperature of the insulation layer 3 so that it is controlled at 35 ± 1°C; the voltage of the potential control device 13 is controlled at 0.4 V; the wet gas flow meter 14 records the daily biogas production; the pressure gauge 2 records the permeable membrane of the fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com