Method for synthesizing ε-caprolactone

A technology of caprolactone and cyclohexanone, which is applied in the continuous process field of synthesizing ε-caprolactone, can solve the problems of difficulty in large-scale production, high separation cost, and long process flow, so as to avoid the decline of product yield and high Conversion rate, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

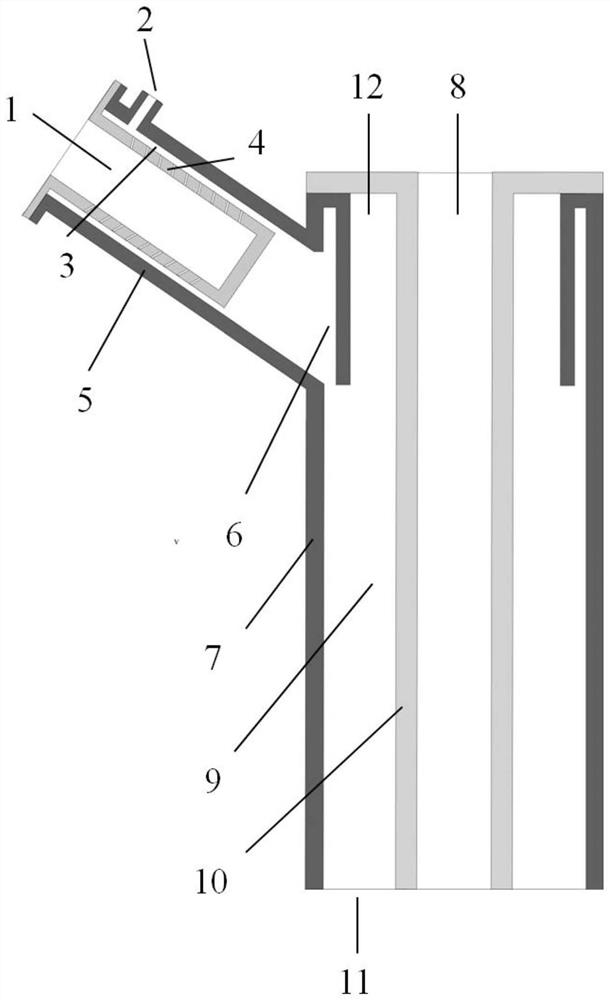

Method used

Image

Examples

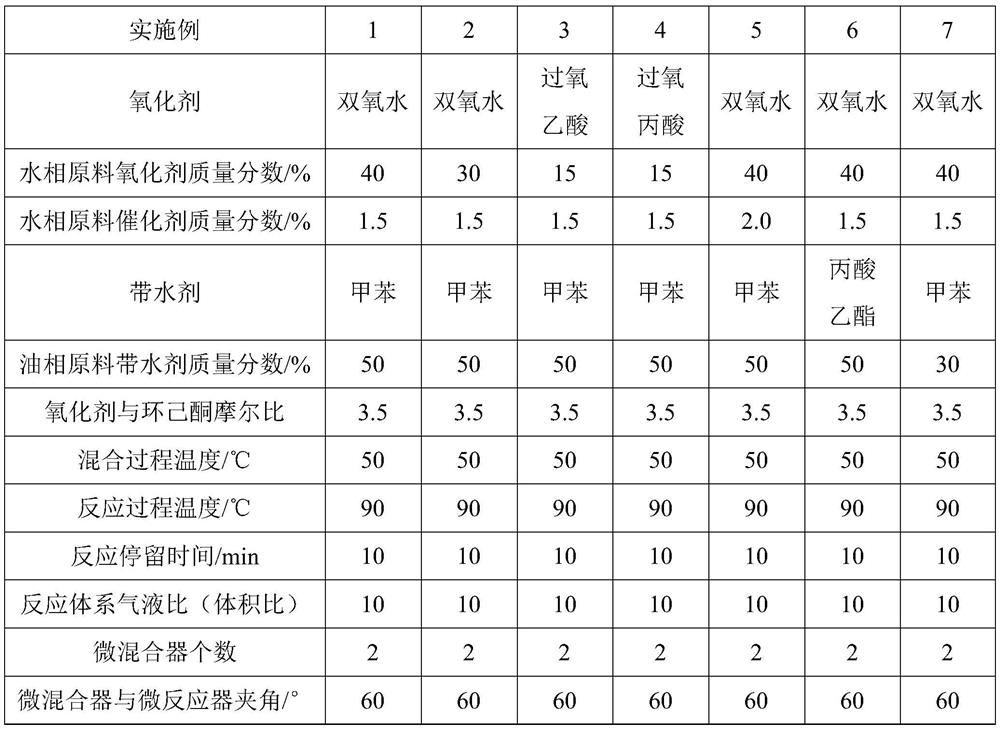

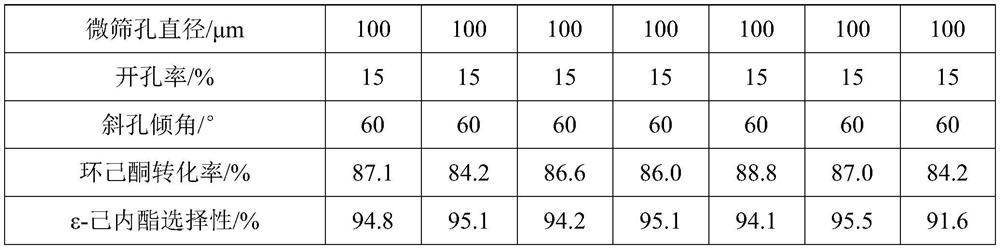

Embodiment 1

[0014] Use a metering pump to transport the aqueous phase raw material containing oxidant and catalyst, wherein the mass fraction of hydrogen peroxide is 40%, the mass fraction of catalyst is 1.5%, and the molar ratio of oxalic acid and sodium tungstate in the catalyst is 1.0; The oil phase raw material, wherein the water-carrying agent toluene mass fraction is 50%. The molar ratio of the oxidant in the water phase raw material to the cyclohexanone in the oil phase raw material is 3.5, and the two streams of materials are respectively preheated by a preheater and fully mixed in a micro mixer at 50°C. The liquid at the outlet of the micro-mixer enters the micro-reactor as a liquid-phase raw material through the connecting pipeline, enters the micro-reactor through the liquid-phase raw material inlet, and contacts with the air entering from the lower gas-phase inlet in countercurrent to carry out the cyclohexanone oxidation reaction. The heating medium in the tube wall provides ...

Embodiment 2

[0016] Use a metering pump to transport the aqueous phase raw material containing oxidant and catalyst, wherein the mass fraction of hydrogen peroxide is 30%, the mass fraction of catalyst is 1.5%, and the molar ratio of oxalic acid to sodium tungstate in the catalyst is 1.0; The oil phase raw material, wherein the water-carrying agent toluene mass fraction is 50%. The molar ratio of the oxidizing agent in the water phase raw material to the cyclohexanone in the oil phase raw material is 3.5, and the two streams of materials are respectively preheated by a preheater and fully mixed in a micro mixer at 50°C. The liquid at the outlet of the micro-mixer enters the micro-reactor as a liquid-phase raw material through the connecting pipeline, enters the micro-reactor through the liquid-phase raw material inlet, and contacts with the air entering from the lower gas-phase inlet in countercurrent to carry out the cyclohexanone oxidation reaction. The heating medium in the tube wall pr...

Embodiment 3

[0018]Use a metering pump to transport the aqueous phase raw material containing oxidant and catalyst, wherein the mass fraction of peracetic acid is 15%, the mass fraction of catalyst is 1.5%, and the molar ratio of oxalic acid and sodium tungstate in the catalyst is 1.0; The oil phase raw material of the water agent, wherein the toluene mass fraction of the water agent is 50%. The molar ratio of the oxidizing agent in the water phase raw material to the cyclohexanone in the oil phase raw material is 3.5, and the two streams of materials are respectively preheated by a preheater and fully mixed in a micro mixer at 50°C. The liquid at the outlet of the micro-mixer enters the micro-reactor as a liquid-phase raw material through the connecting pipeline, enters the micro-reactor through the liquid-phase raw material inlet, and contacts with the air entering from the lower gas-phase inlet in countercurrent to carry out the cyclohexanone oxidation reaction. The heating medium in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com