Heterotopic electron compensation hydrogen autotrophic denitrification nitrogen removal device

An autotrophic denitrification and denitrification technology, which is applied in the direction of electrochemical bio-combination treatment, anaerobic digestion treatment, chemical instruments and methods, etc., can solve the problems of low rate and low denitrification efficiency, and achieve increased solubility and enhanced denitrification Nitrogen efficiency, effect of improving hydrogen utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

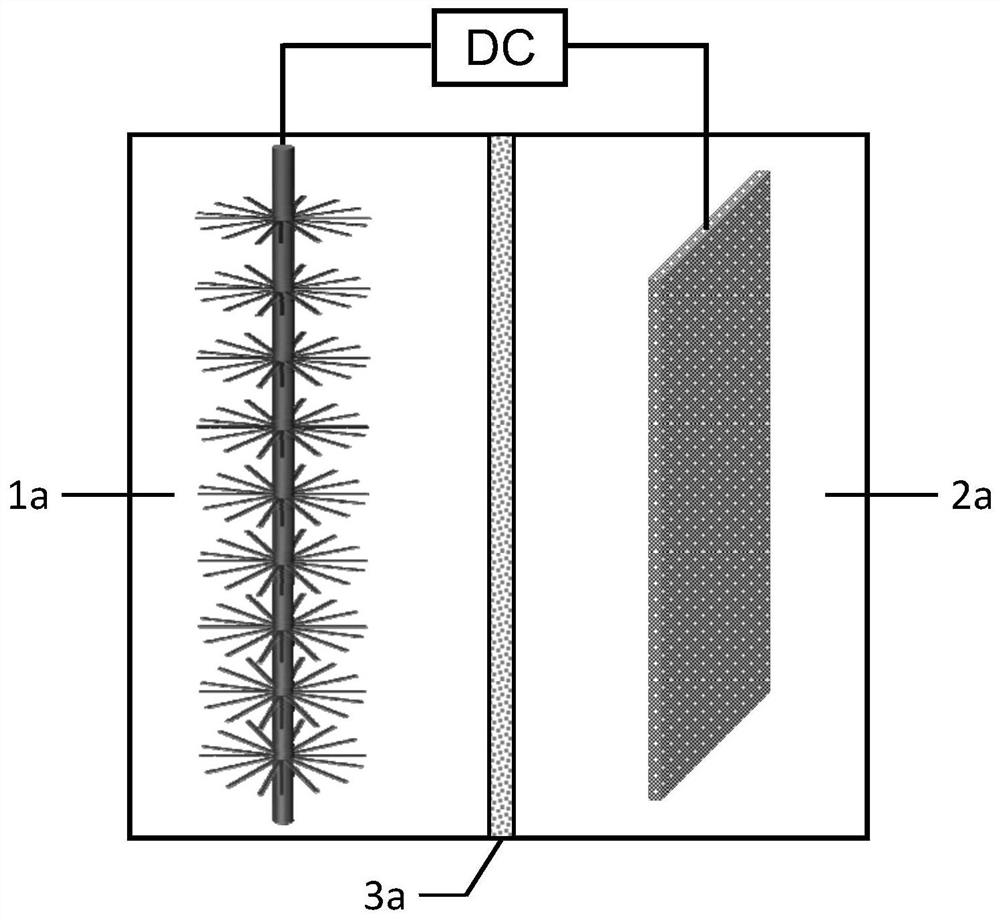

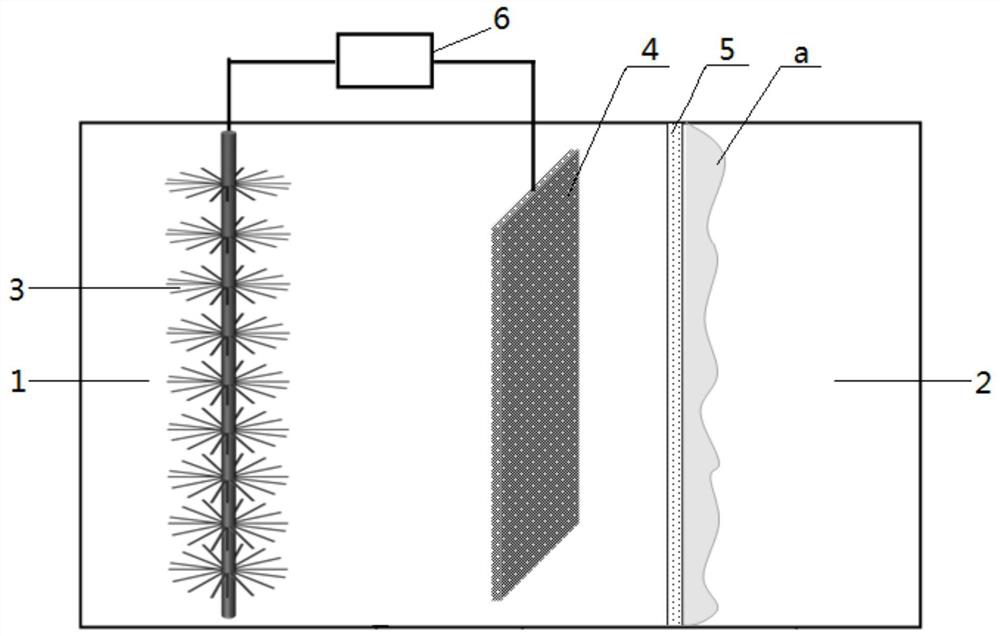

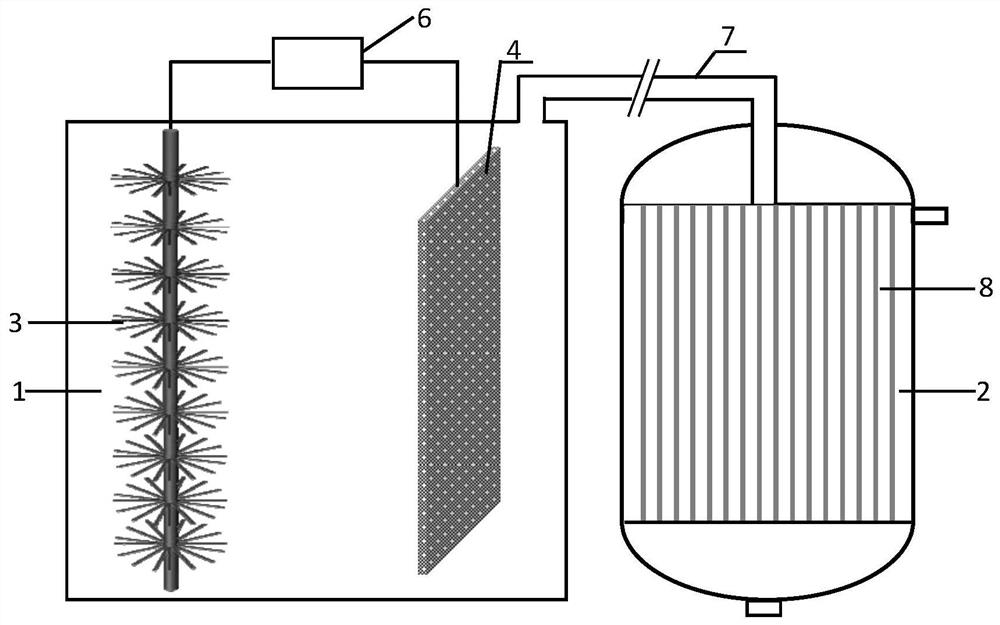

[0020] Specific Embodiment 1: The hydrogen autotrophic denitrification denitrification device compensated by ectopic electrons in this embodiment is composed of a hydrogen production chamber 1, a denitrification chamber 2, an anode 3, a cathode 4, a gas diffusion membrane 5 and a DC power supply 6 to produce hydrogen The chamber 1 and the denitrification chamber 2 are separated by a gas diffusion membrane 5, the anode 3 and the cathode 4 are arranged in the hydrogen production chamber 1, the DC power supply 6 is arranged outside the hydrogen production chamber 1, and the anode 3 is connected to the positive pole of the DC power supply 6, The cathode 4 is connected to the negative pole of the DC power supply 6 .

[0021] The beneficial effects of this embodiment are:

[0022] 1. The device of this embodiment is equipped with a gas diffusion device, and the hydrogen gas is slowly released into the nitrate-contaminated water body to increase the solubility of hydrogen gas in wate...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that: the gas diffusion membrane 5 is a flat gas diffusion membrane or a hollow fiber membrane.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the material of the anode 3 is a biocompatible conductive electrode; the biocompatible conductive electrode is a carbon brush, carbon cloth , carbon fiber cloth, titanium mesh, stainless steel mesh, carbon felt, carbon fiber brush, granular activated carbon or biochar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com