Nano-fiber curing agent for disintegrating carbonaceous mudstone and its preparation and use methods

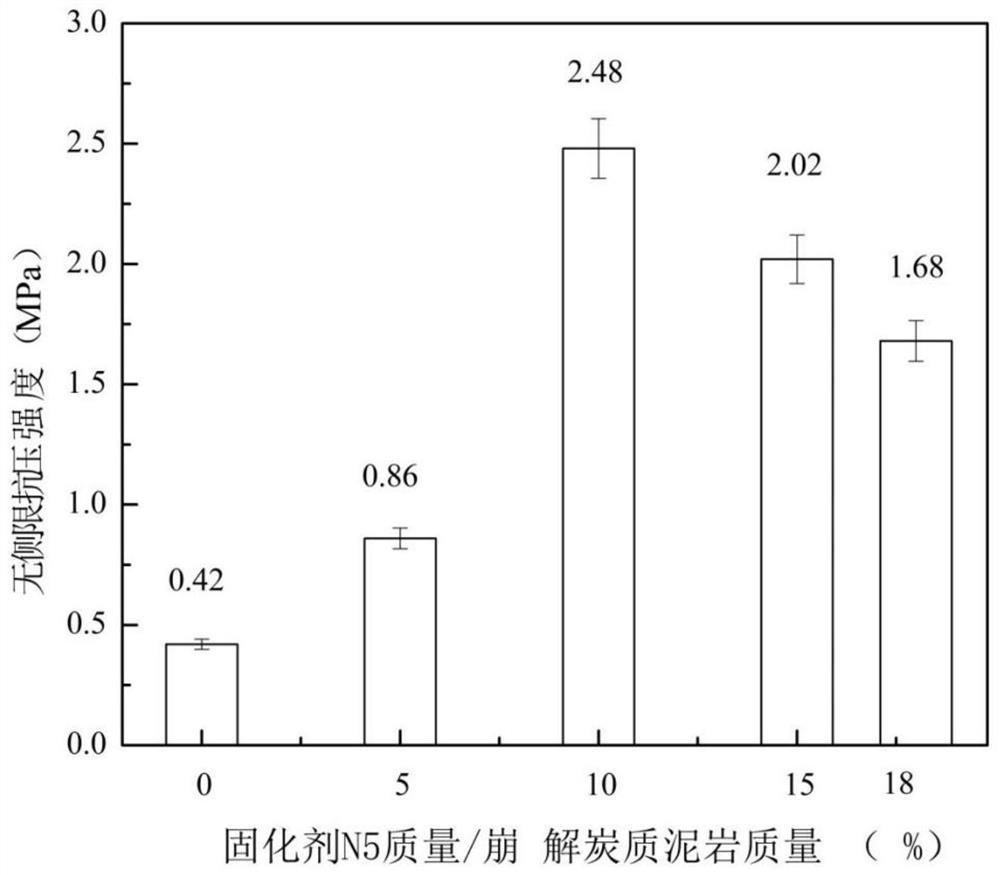

A carbonaceous mudstone and fiber solidification technology, applied in the field of geotechnical engineering materials, can solve problems such as large seasonal changes in atmospheric temperature and humidity, instability and damage of embankments and slopes, and shortened road service life, and achieve good solidification effect. , good durability, reducing the effect of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of the nano-fiber solidifying agent used for disintegrating carbonaceous mudstone is specifically carried out according to the following steps:

[0043] S1, weighed according to the following parts by weight: 32 parts of 42.5 grade Portland slag cement, nanometer Al 2 o 3 2 parts, 1 part of nano-montmorillonite, 10 parts of poly-tert-butylacrylamide hydrogel, 1 part of disodium edetate, 35 parts of slag, 3 parts of glass fiber material, 16 parts of water;

[0044] S2, at 10°C, the weighed poly-tert-butylacrylamide hydrogel, disodium ethylenediaminetetraacetic acid and nano-Al 2 o 3 1. Dissolve nano-montmorillonite in an appropriate amount of absolute ethanol to obtain a fully dissolved mixed solution. Add 70% of 16 parts of water to the mixed solution, and the ultrasonic stirring rate is 1000 rpm, and stir for 0.1h until uniform, and the curing agent is prepared. ;

[0045] S3, at 10°C, put the expected curing agent, the weighed glass fiber ma...

Embodiment 2

[0049] The preparation method of the nano-fiber solidifying agent used for disintegrating carbonaceous mudstone is specifically carried out according to the following steps:

[0050] S1, weighed according to the following parts by weight: 34 parts of 42.5 grade Portland slag cement, nanometer CaCO 3 3 parts, 1 part of nano-montmorillonite, 8 parts of poly-tert-butylacrylamide hydrogel, 1 part of disodium edetate, 30 parts of slag, 3 parts of ceramic fiber material, 20 parts of water;

[0051] S2. At 25°C, the weighed poly-tert-butylacrylamide hydrogel, disodium ethylenediaminetetraacetic acid and nano-CaCO 3 1. Dissolve nano-montmorillonite in an appropriate amount of absolute ethanol to obtain a fully dissolved mixed solution, add 70% of 20 parts of water to the mixed solution, and ultrasonically stir at 1200 rpm, stir for 0.1h until uniform, and prepare the curing agent. ;

[0052] S3, at 25°C, put the expected curing agent, the weighed ceramic fiber material, and the weig...

Embodiment 3

[0056] The present invention is used for the preparation method of the nano-fiber curing agent of disintegrating carbonaceous mudstone, specifically carries out according to the following steps:

[0057] S1, weighed according to the following parts by weight: 40 parts of 42.5 grade ordinary Portland cement, nanometer Al 2 o 3 1 part, 1 part of nano-montmorillonite, 6.5 parts of polymethylenebisacrylamide hydrogel, 0.5 part of disodium edetate, 25 parts of slag, 6 parts of quartz fiber material, 20 parts of water;

[0058] S2. At 35°C, the weighed polymethylenebisacrylamide hydrogel, disodium ethylenediaminetetraacetic acid and nano-Al 2 o 3 1. Dissolve nano-montmorillonite in an appropriate amount of absolute ethanol to obtain a fully dissolved mixed solution. Add 70% of 25 parts of water into the mixed solution, and the ultrasonic stirring rate is 1000 rpm, and stir for 0.1h until uniform, and the curing agent is prepared. ;

[0059] S3, at 35°C, place the expected curing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com