Production process of medicinal raw material sodium methoxide

A production process, the technology of sodium methoxide, is applied in the field of production process of sodium methoxide, a medical raw material, which can solve the problems of insufficient utilization of raw materials, high energy consumption of methanol recovery, and easy residue of metal sodium, so as to achieve reasonable design and improve Utilization rate, the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

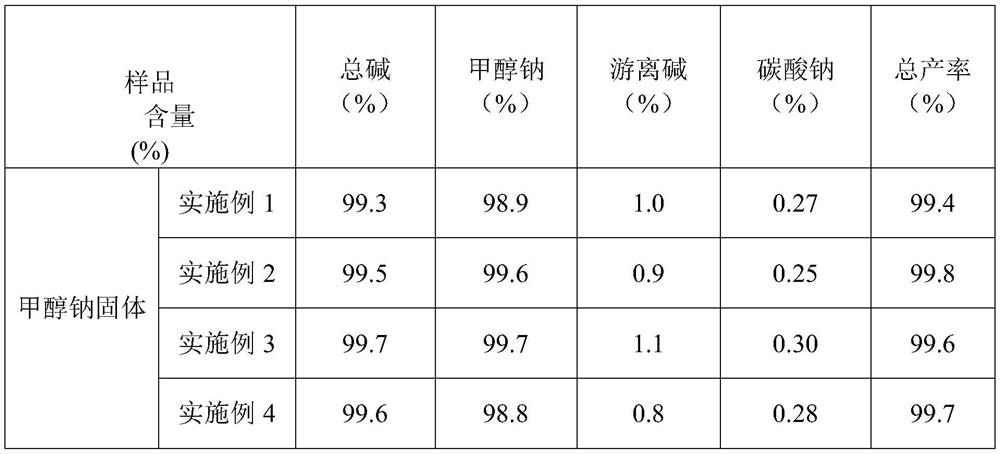

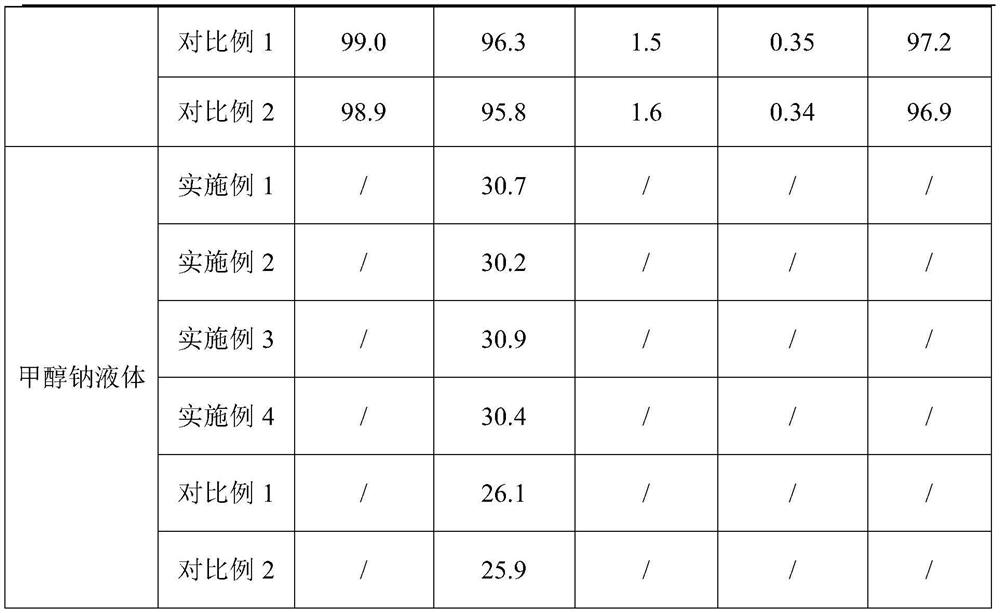

Examples

Embodiment 1

[0023] A production process of medicinal raw material sodium methylate, comprising the following steps:

[0024] Step S1: In the reaction kettle, according to the solid-to-liquid mass ratio of 1:10, add molten sodium metal, slowly add the condensed methanol liquid into the reaction kettle under stirring conditions, and continuously feed into the reaction solution in the reaction kettle Nitrogen;

[0025] Step S2: Under normal pressure at 80°C, metal sodium and methanol liquid were reacted for 3 hours, and after the reaction was complete, a mixed solution of sodium methanolate was obtained;

[0026] Step S3: heat-filter the sodium methanolate mixed solution obtained in step S2 to obtain the filter residue and the target solution, the filter residue enters the next process, the target solution is distilled and dried under negative pressure to obtain sodium methoxide, and the discharged methanol gas is condensed and then enters the reaction kettle again continue to react;

[00...

Embodiment 2

[0029] A production process of medicinal raw material sodium methylate, comprising the following steps:

[0030] Step S1: In the reaction kettle, according to the solid-to-liquid mass ratio of 1:11, add molten sodium metal, slowly add the condensed methanol liquid into the reaction kettle under stirring conditions, and continuously feed into the reaction solution in the reaction kettle Nitrogen;

[0031] Step S2: Under normal pressure at 85°C, the metal sodium and methanol liquid were reacted for 2.5 hours. After the reaction was complete, a mixed solution of sodium methanolate was obtained;

[0032] Step S3: heat-filter the sodium methanolate mixed solution obtained in step S2 to obtain the filter residue and the target solution, the filter residue enters the next process, the target solution is distilled and dried under negative pressure to obtain sodium methoxide, and the discharged methanol gas is condensed and then enters the reaction kettle again continue to react;

[...

Embodiment 3

[0035] A production process of medicinal raw material sodium methylate, comprising the following steps:

[0036] Step S1: In the reaction kettle, according to the solid-liquid mass ratio of 1:12, add powdered sodium metal with a particle size of 500nm, slowly add the condensed methanol liquid into the reaction kettle under stirring conditions, and add to the reaction kettle. Continuously inject argon into the liquid;

[0037] Step S2: Under normal pressure at 90°C, metal sodium and methanol liquid were reacted for 2 hours, and after complete reaction, a mixed solution of sodium methanolate was obtained;

[0038] Step S3: heat-filter the sodium methanolate mixed solution obtained in step S2 to obtain the filter residue and the target solution, the filter residue enters the next process, the target solution is distilled and dried under negative pressure to obtain sodium methoxide, and the discharged methanol gas is condensed and then enters the reaction kettle again continue to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com