Application of multifunctional interpenetrating network polymer emulsion in polyurethane flexible foam plastic modification

A technology of polymer emulsion and polyurethane soft foam, which is applied in the field of polyvinylpyrrolidone chain and alkoxy polyethylene glycol, and can solve the problems of reduced concentration of antibacterial agents, poor safety of inorganic antibacterial agents, and uncertain safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

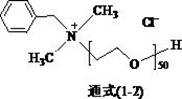

[0045] Weigh 40 grams of 6950F brand toluene isocyanate trimer with a solid content of about 50% produced by Shandong Wanhua Company and add it to the reaction kettle, then add 22 grams of polyethylene glycol-2000 monomethyl ether, 30 grams of quality The average molecular weight is 2000 single-terminal hydroxyl polyvinylpyrrolidone, 25 grams of hydroxyl-terminated polyether quaternary ammonium salts of structure shown in formula (1-1), 0.18 gram of dibutyltin dilaurate, 0.13 gram of triethylenediamine add reaction Kettle, N 2 Under protection and stirring, control the temperature of the material in the reactor to 50-65°C, and control the reaction time of gradual addition polymerization for 2 hours; then add 25 grams of dry-processed 2,000 mass average molecular weight produced by Shandong Lanxing Dongda Chemical Co., Ltd. Polyether diol DL-2000D, 3.5 grams of glycerin and 12 grams of toluene diisocyanate (TDI80 / 20), react at a temperature of 70~80°C for 2 hours; when the mate...

Embodiment 2

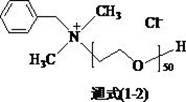

[0052] According to the method and operating steps of Example 1, the formula (1-1) hydroxyl-terminated polyether quaternary ammonium salt in Example 1 is replaced by formula (1-2) hydroxyl-terminated polyether quaternary ammonium salt, toluene isocyanate trimer Change to diphenylmethane diisocyanate trimer, and toluene diisocyanate to diphenylmethane diisocyanate to prepare multifunctional interpenetrating network polymer-2 emulsion.

[0053] Wherein formula (1-2) hydroxyl-terminated polyether quaternary ammonium salt structure is as follows:

[0054]

[0055] Set the relative density to 0.85 g / cm 3 、The cell diameter is 40~120 µm, the opening rate is 70~90%, and the moisture permeability is 3600 g / cm under normal conditions 2 24 hours of commercially available 10*2*0.2 cm polyurethane soft foam sheets were placed in ethanol, ultrasonically cleaned for 30 minutes, taken out and dried, then immersed in the multi-functional interpenetrating network polymer-1 emulsion and squ...

Embodiment 3

[0057] According to the method and operation steps of embodiment 1, the formula (1-1) hydroxyl-terminated polyether quaternary ammonium salt in embodiment 1 is changed into formula (1-3) hydroxyl-terminated polyether quaternary ammonium salt, polyethylene glycol- 2000 monomethyl ether is replaced by polyethylene glycol-2000 monolauryl ether, toluene isocyanate trimer is replaced by diphenylmethane diisocyanate trimer, toluene diisocyanate is replaced by diphenylmethane diisocyanate, and multifunctional Interpenetrating network polymer-3 emulsion.

[0058] Wherein formula (1-3) hydroxyl-terminated polyether quaternary ammonium salt structure is as follows:

[0059]

[0060] Set the relative density to 0.18 g / cm 3 , The cell diameter is 200~400 µm, the opening rate is 70~90%, and the moisture permeability is 8600 g / cm under normal conditions 2 24 hours of commercially available 10*2*0.2 cm polyurethane soft foam sheets were placed in ethanol, ultrasonically cleaned for 30 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com