High-flame-retardant artistic coating and preparation method thereof

An art paint, high flame retardant technology, applied in the direction of fire-resistant paint, multi-color effect paint, coating, etc., can solve the problems of easy burning and damage of products, and achieve strong layering, good hand feel and excellent scratch resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

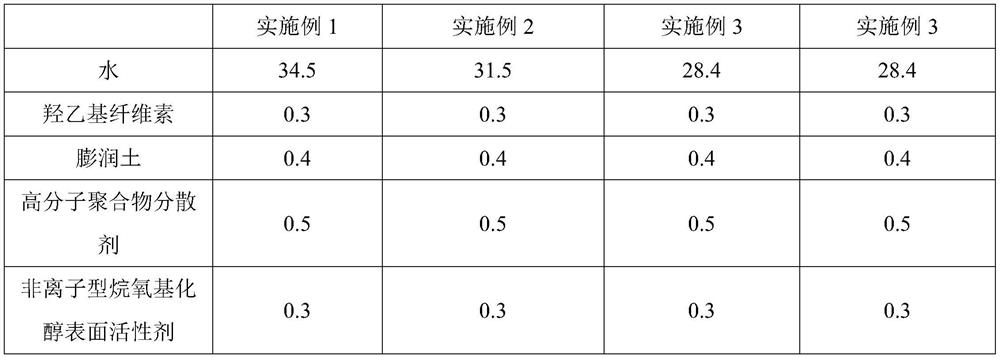

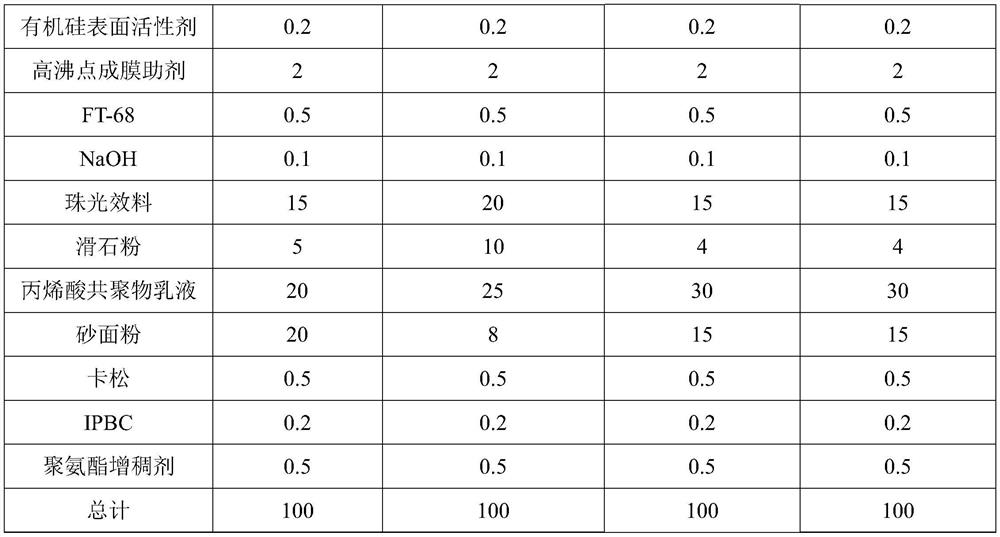

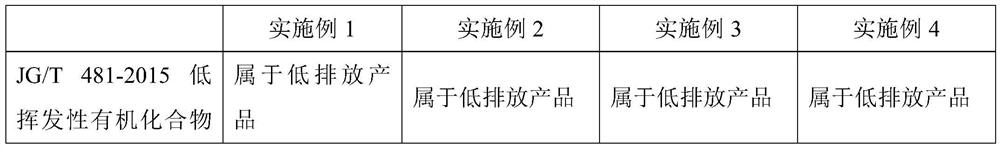

Examples

Embodiment 4

[0050] The pearlescent effect material of embodiment 4 is colorful art resin, and concrete preparation method is as follows:

[0051] The preparation method of colorful artistic resin of the embodiment of the present invention is as follows:

[0052] Step 1: Take 25 parts by weight of hydroxyacrylate and 25 parts by weight of aminoacrylate in 30 parts by weight of water, add 5 parts by weight of 1-100nm mica powder, and shake to form a uniform mixed solution;

[0053] Step 2: Take the mixed solution for coating and curing, and dry at 150°C for 4 hours to form a coating;

[0054] Step 3: crushing, grinding, and sieving the coating to obtain resin particles of 300-400 mesh;

[0055] Step 4: Soak the resin particles in 50 parts by weight of water, add 10 parts by weight of pigment and 100 parts by weight of hydroxyacrylate and shake and mix well; the pigment is mixed with titanium dioxide and fluorescent green powder in a weight ratio of 1:0.5 .

[0056] Step 5: Take the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com