Porous polymer ion exchange membrane based on polybenzimidazole, preparation method of porous polymer ion exchange membrane by adopting sol-gel method, and application of porous polymer ion exchange membrane

A porous polymer and ion exchange membrane technology, applied in the field of polybenzimidazole-based porous polymer ion exchange membrane, sol-gel method preparation, to achieve easy mass production, avoid the reduction of polymer oxidation stability, broaden the Effects of type and scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

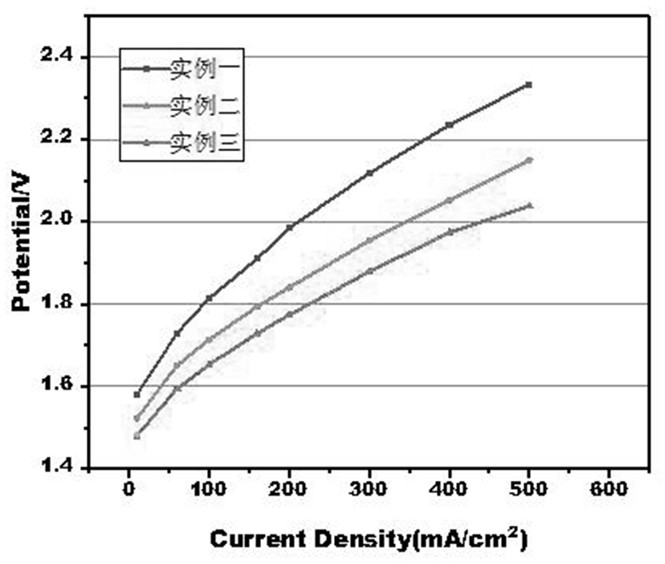

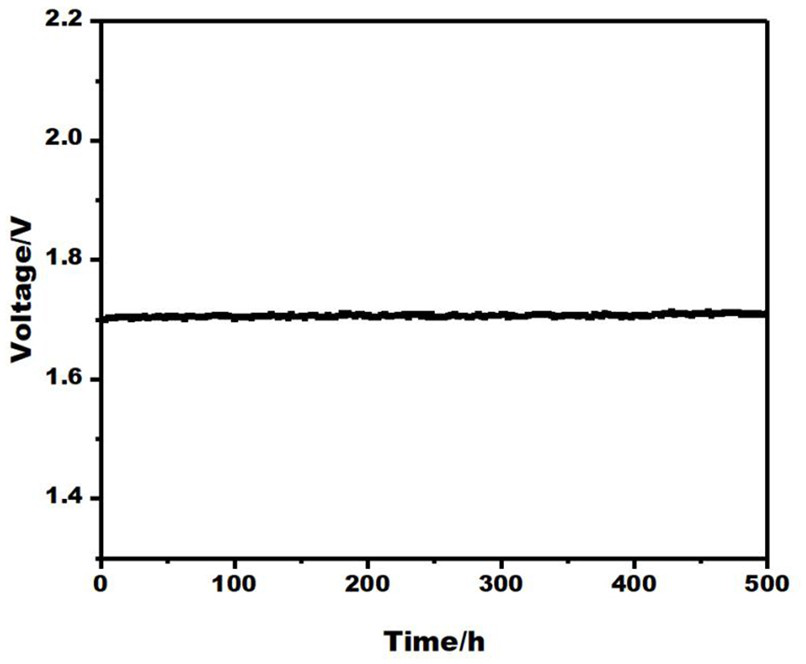

Embodiment 1

[0039] A kind of method adopting sol-gel method to prepare the porous polymer ion-exchange membrane based on polybenzimidazole, comprises the following steps:

[0040] 1. Preparation of stable solution.

[0041] Isophthalic acid (6.230g) and biphenyl tetramine (8.037g) are dissolved in the PPA of 300g, and the pH of adjusting solution is 1, obtains stable, transparent solution, is fully stirred under 110 ℃ at temperature, then in Polymerization at 250°C for 24h;

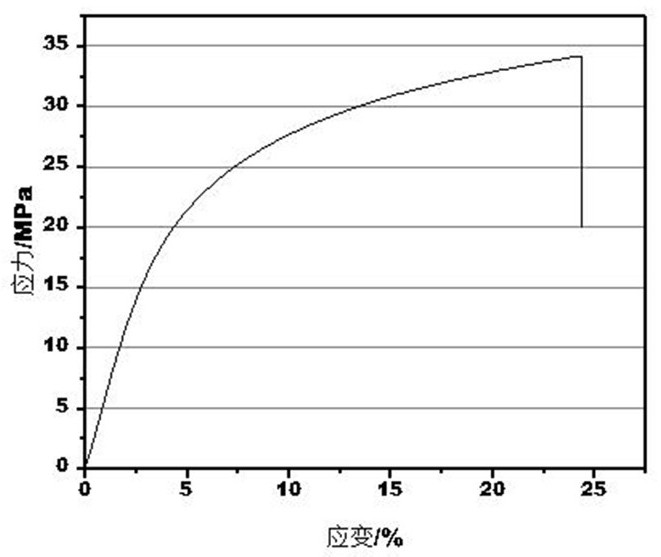

[0042] 2. Preparation of porous polybenzimidazole polymer electrolyte separator by sol-gel method. This step is as follows: slowly immerse the cleaned 20*20cm glass plate in the solution with a temperature of 250°C after polymerization, let it stand for 10 minutes, and pull the glass plate vertically upward at a speed of 0.05m / s. Immediately heat treatment in a steam atmosphere with a humidity of 50% for 24 hours to solidify and form a film, and repeat 5 times to obtain a film with a certain thickness. Soak the me...

Embodiment 2

[0049] A kind of method adopting sol-gel method to prepare the porous polymer ion-exchange membrane based on polybenzimidazole, comprises the following steps:

[0050] 1. The preparation steps of the stable solution are the same as in Example 1.

[0051] 2. Preparation of porous polybenzimidazole polymer electrolyte separator by sol-gel method. This step is as follows: slowly immerse the cleaned 20*20cm glass plate in the solution with a temperature of 250°C after polymerization, let it stand for 10 minutes, and pull the glass plate vertically upward at a speed of 0.05m / s. Immediately heat treatment in a steam atmosphere with a humidity of 60% for 24 hours to solidify and form a film, and repeat 5 times to obtain a film with a certain thickness. Soak the membrane in 1M ammonium hydroxide at 80°C for 12 hours to fully wash away the phosphoric acid in the membrane, then place the membrane in deionized water at 50°C for 12 hours, wash away the residual impurities, and dry it in ...

Embodiment 3

[0054] A kind of method adopting sol-gel method to prepare the porous polymer ion-exchange membrane based on polybenzimidazole, comprises the following steps:

[0055] 1. The preparation steps of the stable solution are consistent with Example 1.

[0056] 2. Preparation of porous polybenzimidazole polymer electrolyte separator by sol-gel method. This step is as follows: slowly immerse the cleaned 20*20cm glass plate in the solution with a temperature of 250°C after polymerization, let it stand for 10 minutes, and pull the glass plate vertically upward at a speed of 0.05m / s. Immediately heat treatment in a steam atmosphere with a humidity of 70% for 24 hours to solidify and form a film, and repeat 5 times to obtain a film with a certain thickness. Soak the membrane in 1M ammonium hydroxide at 80°C for 12 hours to fully wash away the phosphoric acid in the membrane, then place the membrane in deionized water at 50°C for 12 hours, wash away the residual impurities, and dry it in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com