Bulletproof flashboard with heat absorption layer and manufacturing method thereof

A bullet-proof insert and heat-absorbing layer technology, which is applied to chemical instruments and methods, protective clothing, protective equipment, etc., can solve the problem of inability to fully exert the energy-absorbing effect of ultra-high molecular weight polyethylene plates and the ablation of ultra-high molecular weight polyethylene plates To achieve the effect of maintaining energy absorption and improving bulletproof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

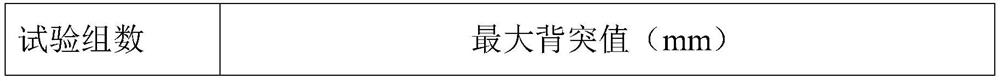

Embodiment 1

[0062] Fabrication of Bulletproof Inserts Containing Phenolic Resin-Based Heat Absorbing Layer

[0063] Phenolic resin 50g, polyvinyl butyral 5g, graphene 10g, particle size are 10000 meshes of magnesium hydroxide 10g, with antifoaming agent n-butanol 0.2g and solvent ethanol 50g, mix in ball mill tank, ball mill 2 hours, obtain fluid Extend the slurry; the ball milling speed is set to 300rpm, and the ball milling ball is an alumina ball with a quality of 400g and a diameter of 4mm;

[0064] The casting slurry is cast into a film on a casting machine, the casting speed is 1m / min, and the height of the scraper is 1mm;

[0065] The temperature in the drying zone is set at 60°C, and after the cast film is dried, a phenolic resin-based heat-absorbing adhesive film is obtained;

[0066] Polyethylene board, phenolic resin-based heat-absorbing adhesive film, heat-absorbing layer aramid cloth, phenolic resin-based heat-absorbing adhesive film, inner crack arrest layer aramid cloth, t...

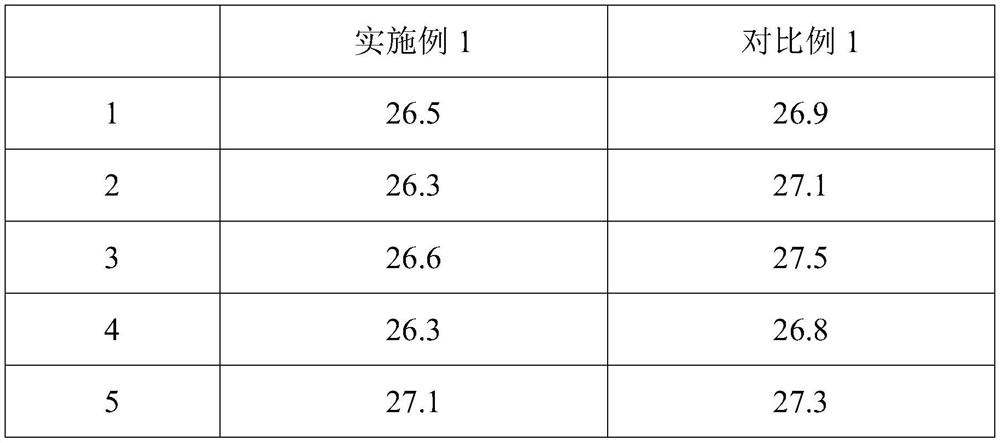

Embodiment 2

[0085] Fabrication of Bulletproof Inserts Containing Epoxy Resin-Based Heat Absorbing Layer

[0086] 50g of bisphenol A epoxy resin with a molecular weight of 4500-6500, 10g of liquid nitrile rubber toughening agent, 5g of carbon nanotubes, 5g of magnesium hydroxide with a particle size of 1000 mesh, and 50g of solvent acetone, mixed in a ball mill tank, and ball milled After 2 hours, add 0.5 g of maleic anhydride, and then continue ball milling for 10 minutes to obtain the coating slurry; the ball milling speed is set to 300 rpm, and the ball milling balls are alumina balls with a mass of 400 g and a diameter of 4 mm;

[0087] Then use a coating machine to coat the slurry on the base film, the curing temperature is 110 ° C, and the curing time is 6 hours to prepare an epoxy resin-based heat-absorbing adhesive film;

[0088] Polyethylene board, epoxy resin-based heat-absorbing adhesive film, heat-absorbing layer aramid cloth, epoxy resin-based heat-absorbing adhesive film, inn...

Embodiment 3

[0105] Fabrication of Bulletproof Inserts Containing Polyurethane-based Heat-absorbing Adhesive Film

[0106] 50g of polyurethane hot-melt adhesive particles with a melting point of 120°C, 1g of silicone leveling agent, 8g of carbon fiber staple fiber, 4g of aluminum hydroxide with a particle size of 1000 mesh, and 50g of solvent acetone are mixed in a ball milling tank, and the flow is obtained after ball milling for 2 hours. Cast the slurry; the ball milling speed is set to 300rpm, and the ball milling ball is an alumina ball with a mass of 400g and a diameter of 4mm; the casting slurry is cast into a film on a casting machine, the casting speed is 0.5m / min, and the height of the scraper is 0.8mm;

[0107] The temperature in the drying zone is set at 90°C, and after the film is dried, a polyurethane-based heat-absorbing film is obtained;

[0108] Polyethylene board, polyurethane-based heat-absorbing adhesive film, heat-absorbing layer aramid cloth, polyurethane-based heat-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com