Processing system and technology of yoghourt modified milk powder

A processing system and milk modulation technology, which is applied in the direction of milk preparations, dairy products, spray evaporation, etc., can solve the problems of fast growth of agglomeration thickness, low effective utilization of equipment, and bacterial growth in spray towers, so as to reduce hanging Good wall volume, good drying effect, and the effect of preventing moisture and caking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is attached Figure 1-9 The application is described in further detail.

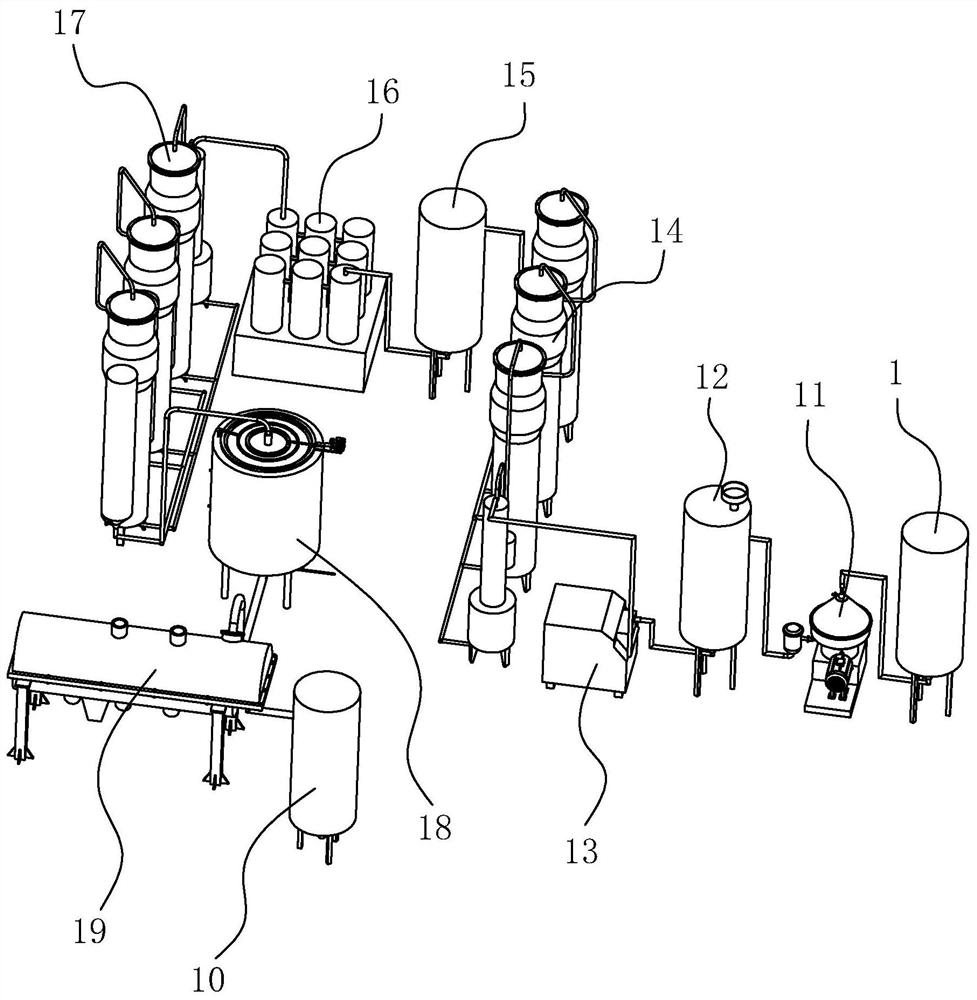

[0045] The embodiment of the present application discloses a processing system for preparing yoghurt milk powder. refer to figure 1 , comprising sequentially connected raw material bin 1, milk cleaner 11, first temporary storage tank 12, homogenizer 13, first falling film evaporator 14, second temporary storage tank 15, fermenter group 16, second falling film Evaporator 17 , spray drying tower 18 , cooling bed 19 and collecting tank 10 .

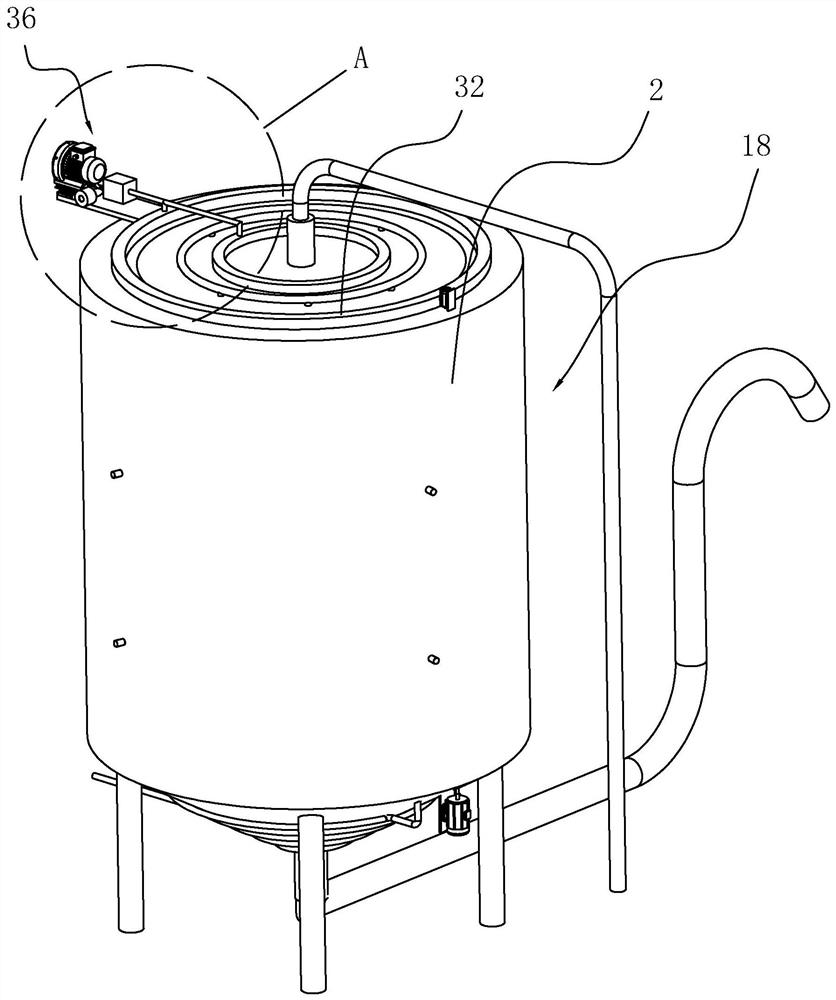

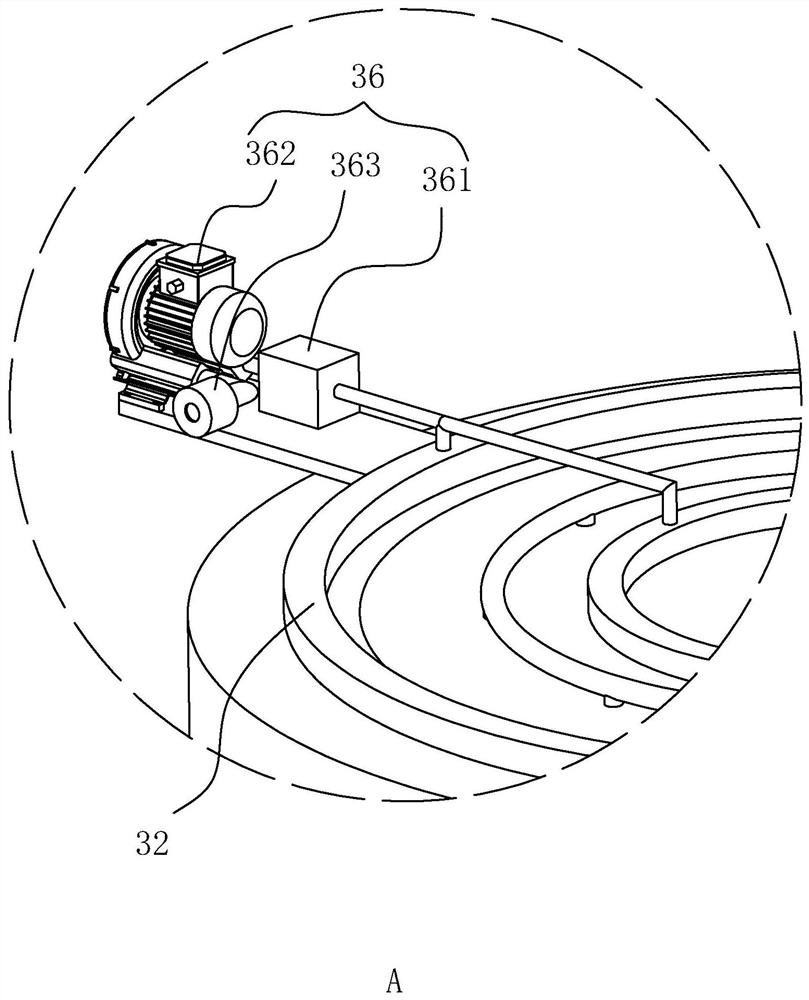

[0046] refer to figure 2 , 3 , The spray drying tower 18 includes a vertical cylindrical shell 2, the top of the shell 2 is provided with a material inlet, and the material inlet is connected to the upper second falling film evaporator 17. There are multiple air inlet passages around the feed inlet on the top of the housing 2 for introducing high-temperature air, and the air inlet passages are connected with a hot air system 36 . The hot air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com