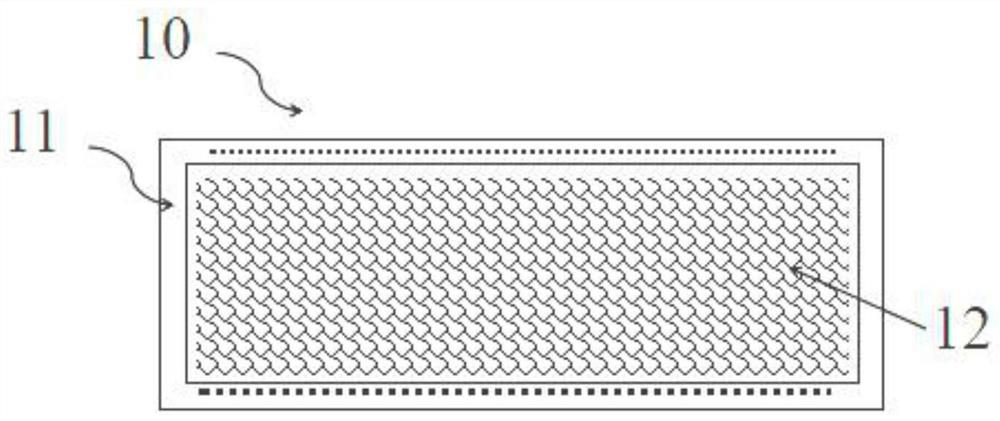

Sandwich integrated exterior wall insulation board and preparation method thereof

An external wall insulation board, an integrated technology, applied in the direction of covering/lining, building, building structure, etc., can solve the problems of lowering fire protection level, cracking failure, insulation performance failure of insulation materials, etc., to achieve excellent bending strength and Compressive strength, easy bonding and fixing, and the effect of avoiding deterioration and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

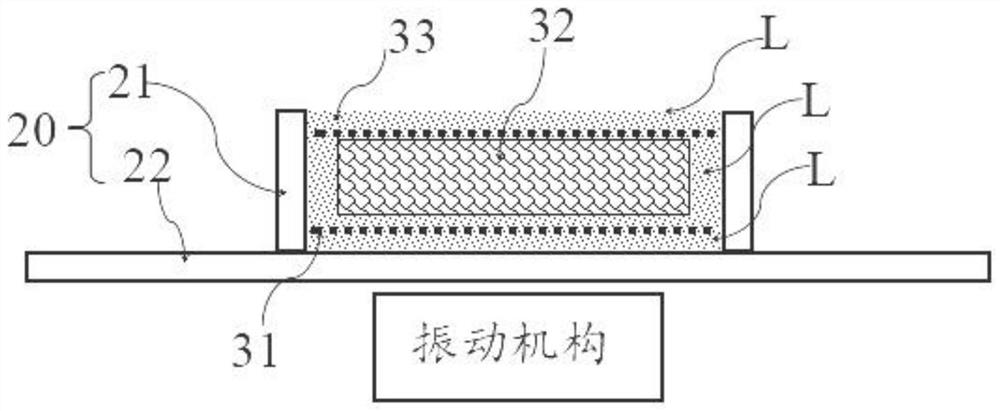

[0081] The preparation method of the insulation board of the present embodiment is as follows:

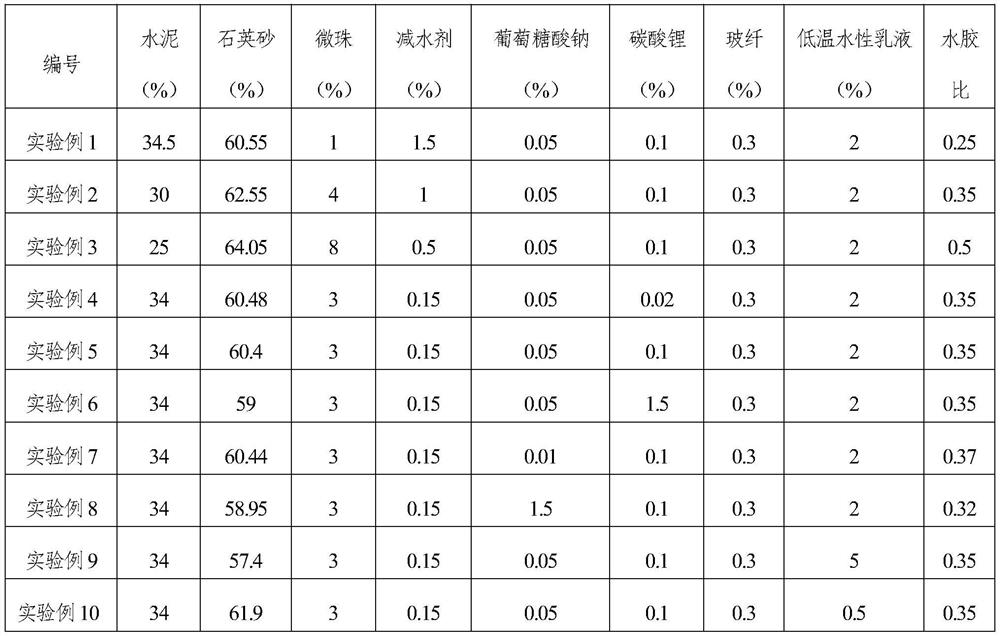

[0082] (1) By mass percentage, mix 42.5R cement 34.5%, 0.01-5mm quartz sand 60.55%, Beijing microbeads 1%, polycarboxylate water reducer 1.5%, lithium carbonate 0.1%, sodium gluconate 0.05%, glass fiber (6mm, Taishan easily dispersible glass fiber) 0.3% and water-based polyacrylic acid emulsion 2.0% were mixed with water, and the water-to-binder ratio was controlled to 0.25. At this time, the mortar ratio was also within the preset range. Stir evenly to obtain the initial automatic fluidity. It is a cement slurry with a fluidity of 234mm.

[0083] (2) Build the mold. Place the mold frame (the size of the inside of the mold frame is 450mm*300mm*40mm) on the surface of the plate. Before injection molding, a layer of nano-silica emulsion with a concentration of 10% was painted on the inner wall of the mold frame and the surface of the flat plate.

[0084] (3) Inject a layer of 6mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com