Method and system for producing 1, 3-propylene glycol by multi-step method

A technology of propylene glycol and multi-step method, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve unsatisfactory problems and achieve low cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

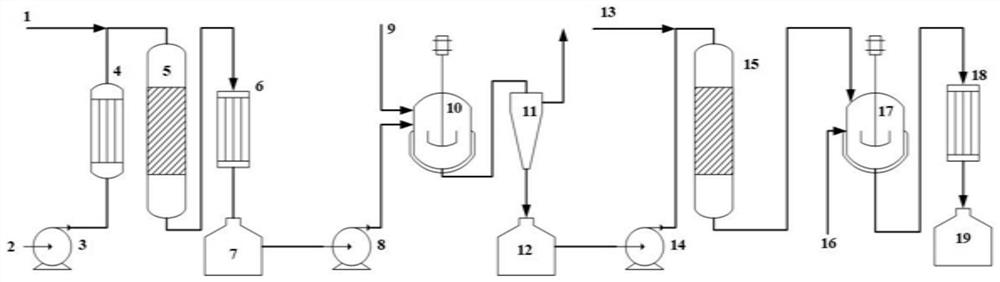

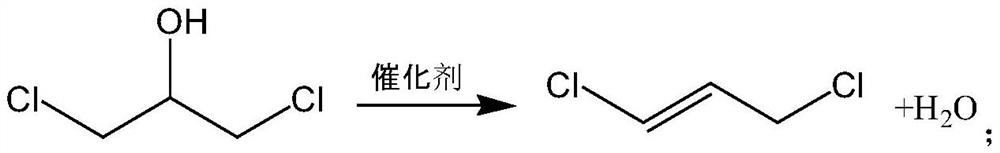

[0102] (1) Dehydration reaction of 1,3-dichloropropanol

[0103] refer to figure 1 As shown, the raw material 1,3-dichloropropanol 2 is transported to the preheating furnace 4 by the transport pump 3, preheated and gasified, and then mixed with the protective gas nitrogen and transported to the dehydration catalyst (Beta Molecular sieve) in the dehydration reactor 5, and at 500 ° C, the liquid hourly space velocity is 3.0h -1 Pass through the dehydration catalyst bed in the dehydration reactor under the conditions and dehydration reaction occurs, and then transported to the dehydration product storage tank 7 after being cooled by the condenser 6 to obtain 1,3-dichloropropanol, 1,3-dichlorohydrin The dehydration product composed of chloropropene, water and other organic matter was analyzed by gas chromatography, and the conversion rate of 1,3-dichloropropanol was measured to be 75%, and the selectivity of 1,3-dichloropropene was 90%;

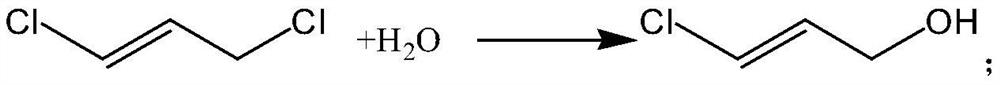

[0104] (2) Hydrolysis reaction of 1,3-di...

Embodiment 2

[0111] (1) Dehydration reaction of 1,3-dichloropropanol

[0112] refer to figure 1 As shown, the raw material 1,3-dichloropropanol 2 is transported to the preheating furnace 4 by the delivery pump 3, preheated and gasified, and then mixed with the protective gas nitrogen and transported to the dehydration catalyst (Al 2 o 3 Loaded phosphotungstic acid, 30%H 3 o 40 PW 12 / Al 2 o 3 ) in the dehydration reactor 5, and at 200°C, the liquid hourly space velocity is 0.1h -1 Pass through the catalyst bed of the dehydration reactor under certain conditions and dehydration reaction occurs, then after being cooled by the condenser 6, it is transported to the dehydration product storage 7 to obtain 1,3-dichloropropene, a small amount of 1,3-dichloropropanol The dehydration product composed of , water and other organic matter was analyzed by gas chromatography, and the conversion rate of 1,3-dichloropropanol was measured to be 83%, and the selectivity of 1,3-dichloropropene was 93%...

Embodiment 3

[0120] (1) Dehydration reaction of 1,3-dichloropropanol

[0121] refer to figure 1 As shown, the raw material 1,3-dichloropropanol 2 is transported to the preheating furnace 4 by the delivery pump 3, preheated and gasified, and then mixed with the protective gas nitrogen and transported to the dehydration catalyst (solid state) loaded with the pipeline through the pipeline. Phosphoric acid, 10% H 3 PO 4 / SiO 2 ) in the dehydration reactor 5, and at 300°C, the liquid hourly space velocity is 2.0h -1 Under the condition of passing through the dehydration reactor and the dehydration reaction takes place, then after being cooled by the condenser 6, it is transported to the dehydration product storage tank 7 to obtain 1,3-dichloropropene, water, a small amount of 1,3-dichloropropanol and other The dehydration product composed of organic matter was analyzed by gas chromatography, and the conversion rate of 1,3-dichloropropanol was measured to be 63%, and the selectivity of 1,3-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com