Nitrogen-phosphorus flame-retardant polybutadiene material and preparation method thereof

A polybutadiene, nitrogen and phosphorus flame retardant technology, applied in the field of polymer chemical synthesis, can solve problems such as poor compatibility, and achieve the effect of durable flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

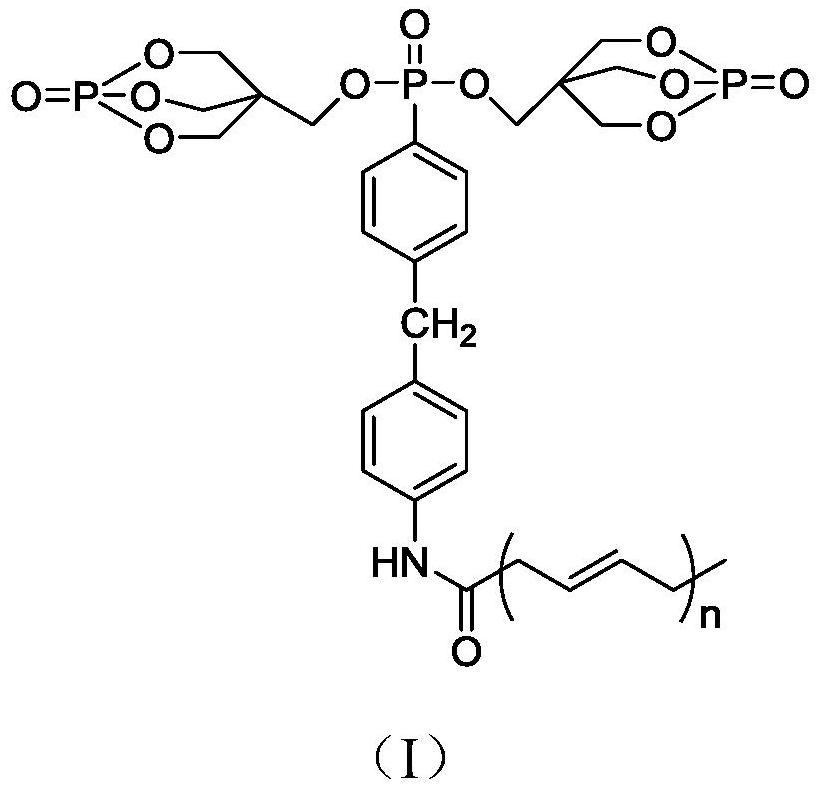

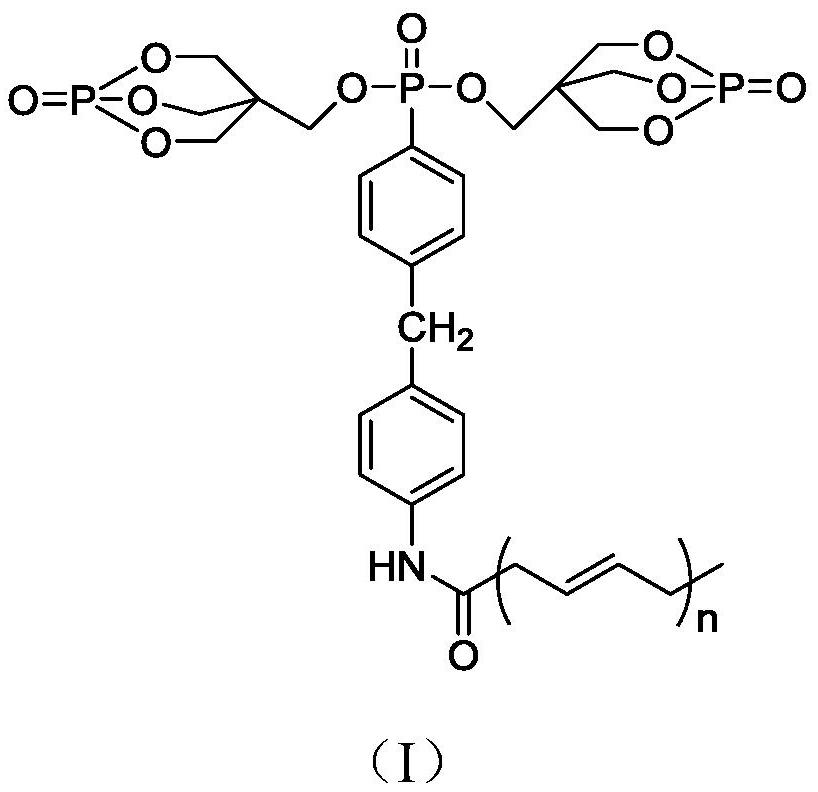

Method used

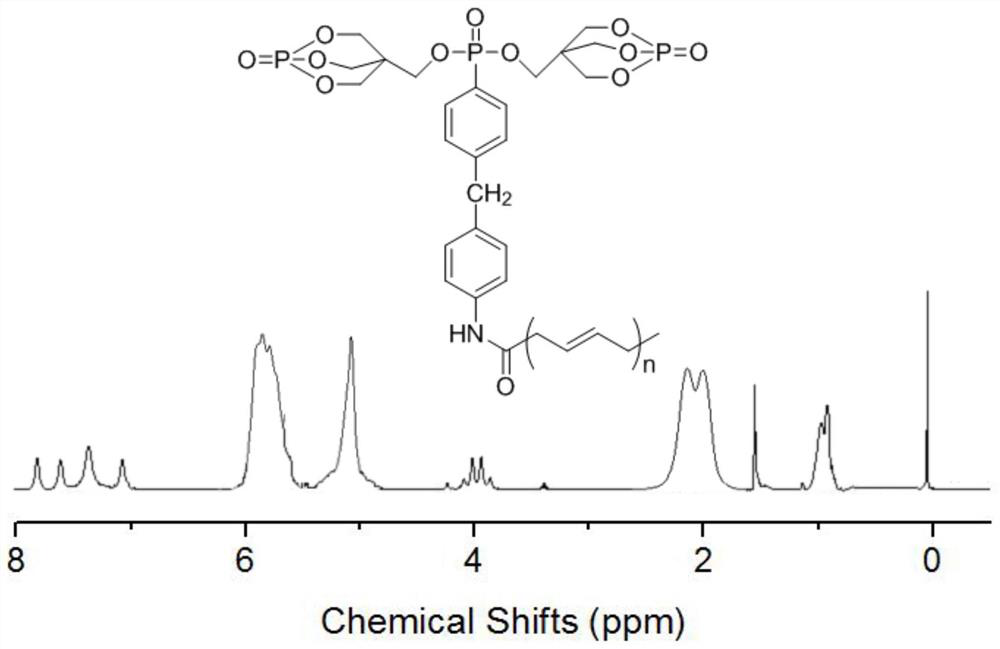

Image

Examples

Embodiment 1

[0024] Add carboxyl-terminated polybutadiene (2.0 mmol) and anhydrous tetrahydrofuran THF into the reactor, and after the reaction temperature rises to 70°C, slowly add SOCl dropwise 2 (10.0mmol), the dropwise addition completed the reaction for 2h, after finishing the reaction, the SOCl was removed by distillation under reduced pressure 2 and THF to obtain a carboxyl-terminated polybutadienyl chloride product with a yield of 78.4%.

Embodiment 2

[0026] Nitrogen-phosphorus flame retardant (1.0mmol) was added into a 50mL Schlenk bottle, and after pumping nitrogen three times, N 2 Under protection, add 30ml of anhydrous toluene to a disposable syringe, raise the temperature to 70°C, inject 1ml of pyridine after the nitrogen and phosphorus flame retardant is completely dissolved, and after stirring for 30min, add the above carboxyl-terminated polybutadienyl chloride dissolved in toluene dropwise The product (10.0mmol) was heated to 80°C and continued to react for 3 hours. The product was cooled to room temperature, and after two cycles of continuous dissolution / precipitation in toluene / methanol, it was dried in vacuum at 45°C to constant weight to obtain nitrogen-phosphorus flame-retardant polybutylene ene material with a yield of 80.2%.

Embodiment 3

[0028] Before processing, vacuum-dry the nitrogen-phosphorus flame-retardant polybutadiene material at 80°C for 12 hours, add 60wt% nitrogen-phosphorus flame-retardant polybutadiene material on an open heat refiner with a twin-roller temperature of 225°C, and wait for it to melt After wrapping and kneading for 10 minutes, the sheets are uniformly released, hot pressed on a flat vulcanizer at 230°C for 10 minutes, cold pressed at room temperature for 8 minutes, and then released. Various standard specimens are prepared on a universal prototype machine for flame retardant performance testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com